Oil fume treatment device

A technology of oil fume treatment and connection device, which is applied in the field of air purification, can solve the problems of difficult to manage water-oil mixture, difficult to manage smoke inlet plate, waste of water resources, etc., to improve work efficiency and service life, avoid waste, reduce pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

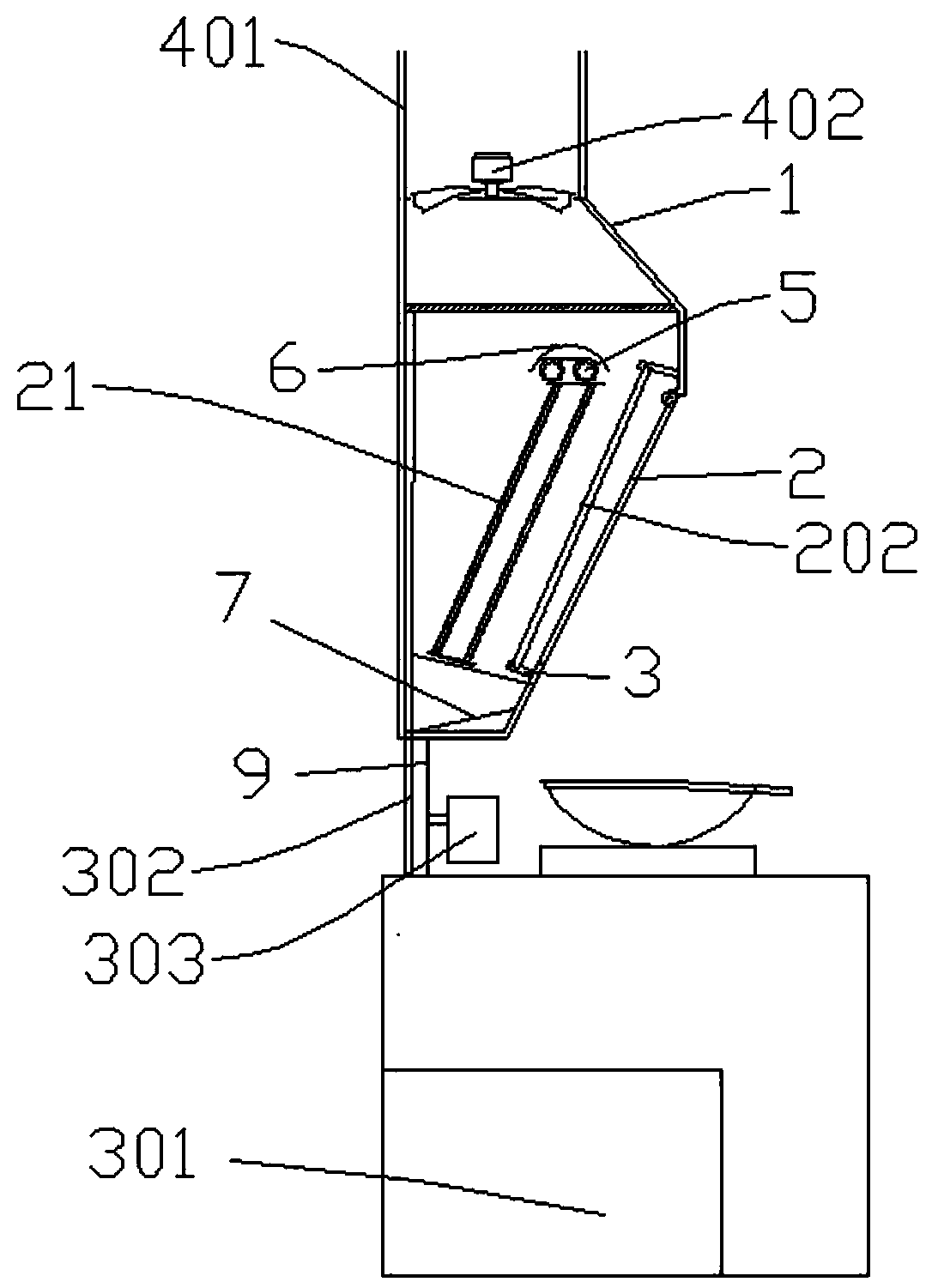

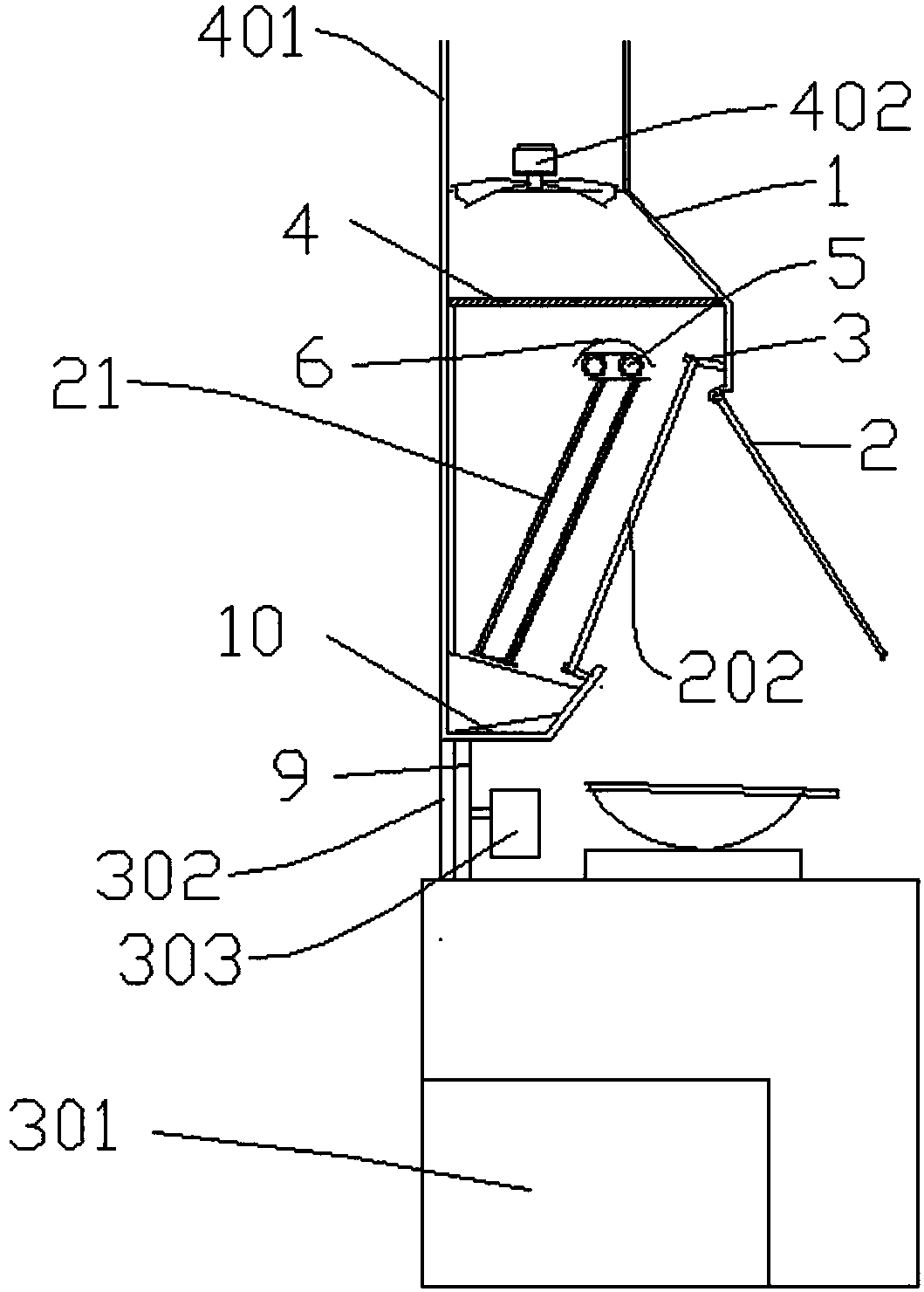

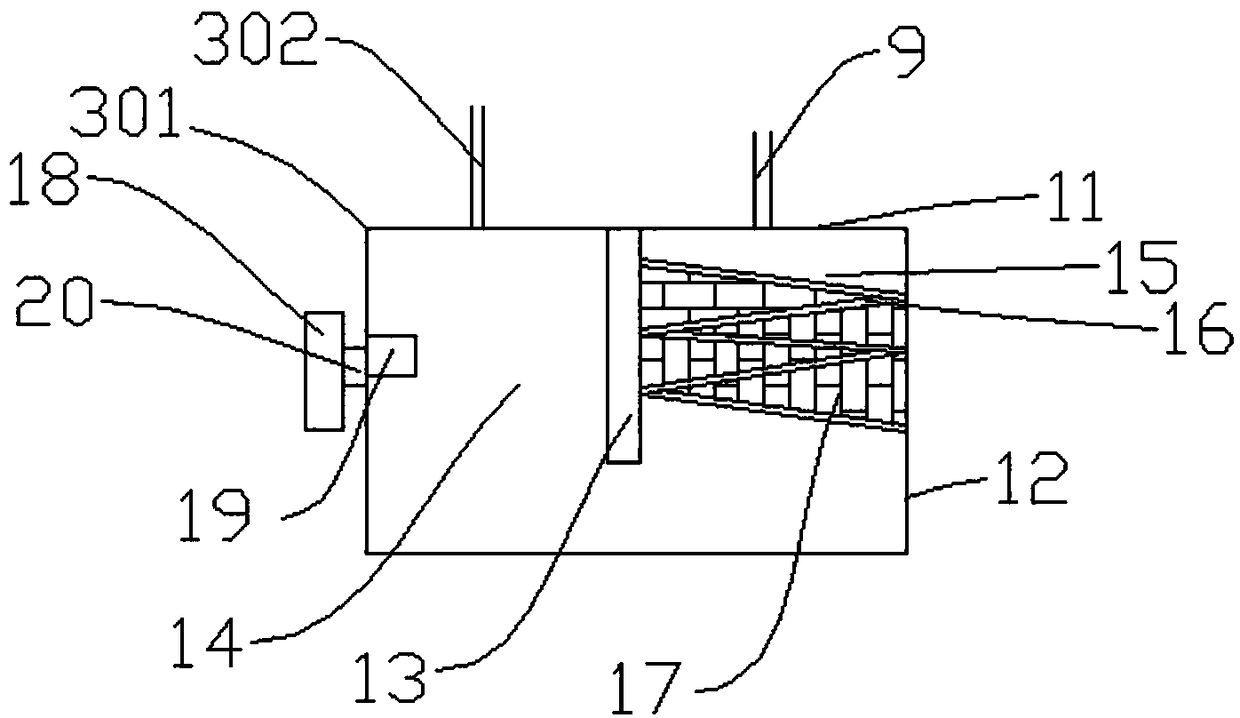

[0021] Combine below Figure 1 to Figure 4 , to further describe the technical solution of the present invention, but not limited to this description.

[0022] An oil fume treatment device, comprising a casing 1, a water circulation system, and a smoke exhaust system. Two smoke inlet plates 2 are movably connected to the front end of the casing 1; a number of smoke inlet holes are uniformly distributed on the smoke inlet plate 2, The inner side of the smoke inlet plate 2 is correspondingly provided with a filter plate 202, and the filter plate 202 is fixedly connected with the casing 1 through a detachable connection device, and the inner side of the smoke inlet plate 2 is correspondingly provided with several layers of filter screens 21, the top of the several layers of filter screens 21 is correspondingly provided with a spray pipe 5 adapted to the length of the filter screen 21, and several spray holes are distributed on the spray pipe 5; the water circulation device includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com