Split type gear, making method of split type gear, correction assembly of split type gear, and correction method of split type gear

A split-type, gear technology, applied to components with teeth, belts/chains/gears, portable lifting devices, etc., can solve the problems of large cumulative errors of presses, troublesome adjustment operations, and heavy workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The following description serves to disclose the invention to enable those skilled in the art to practice the invention. The preferred embodiments described below are given by way of example only, and other obvious modifications will occur to those skilled in the art.

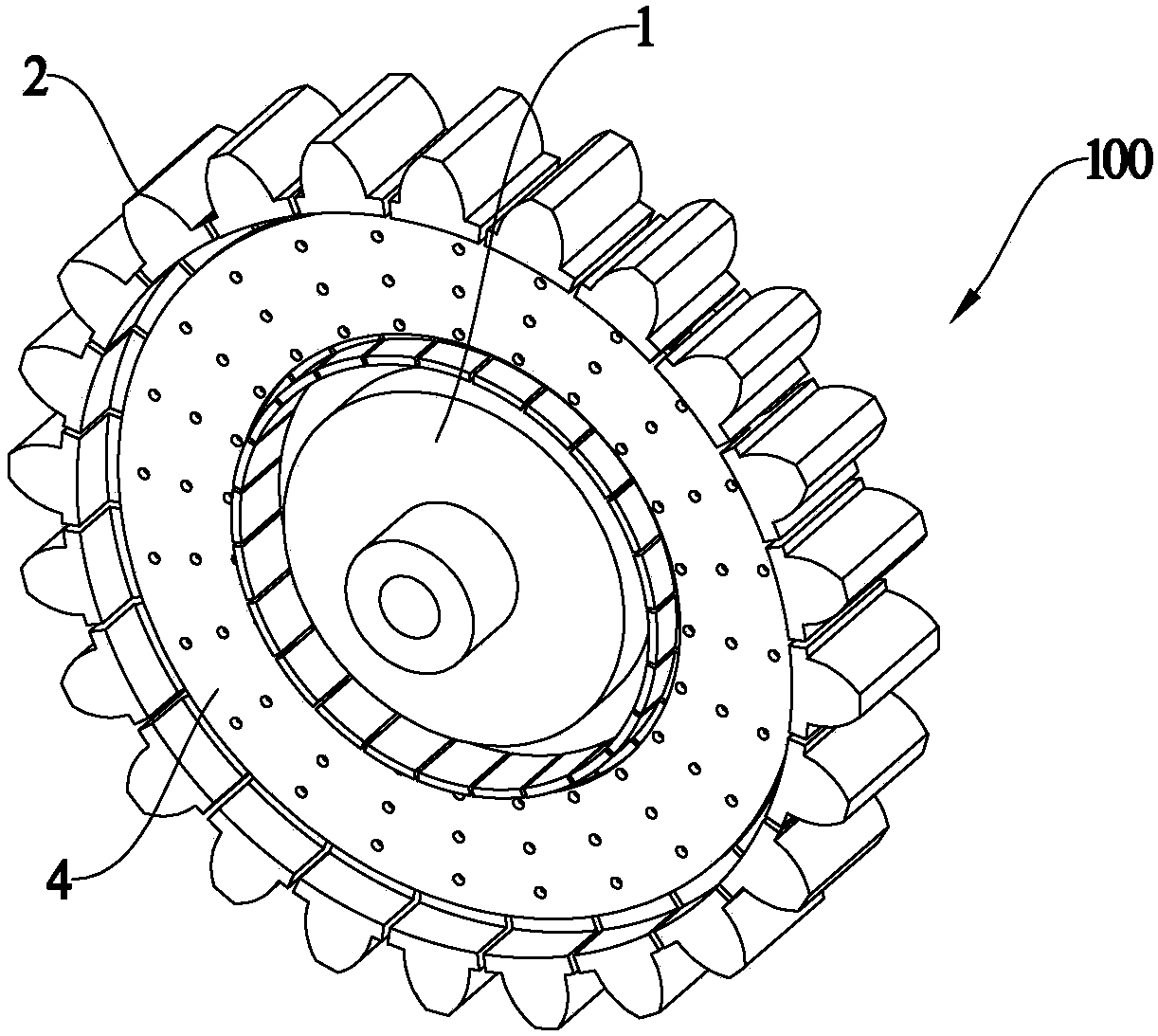

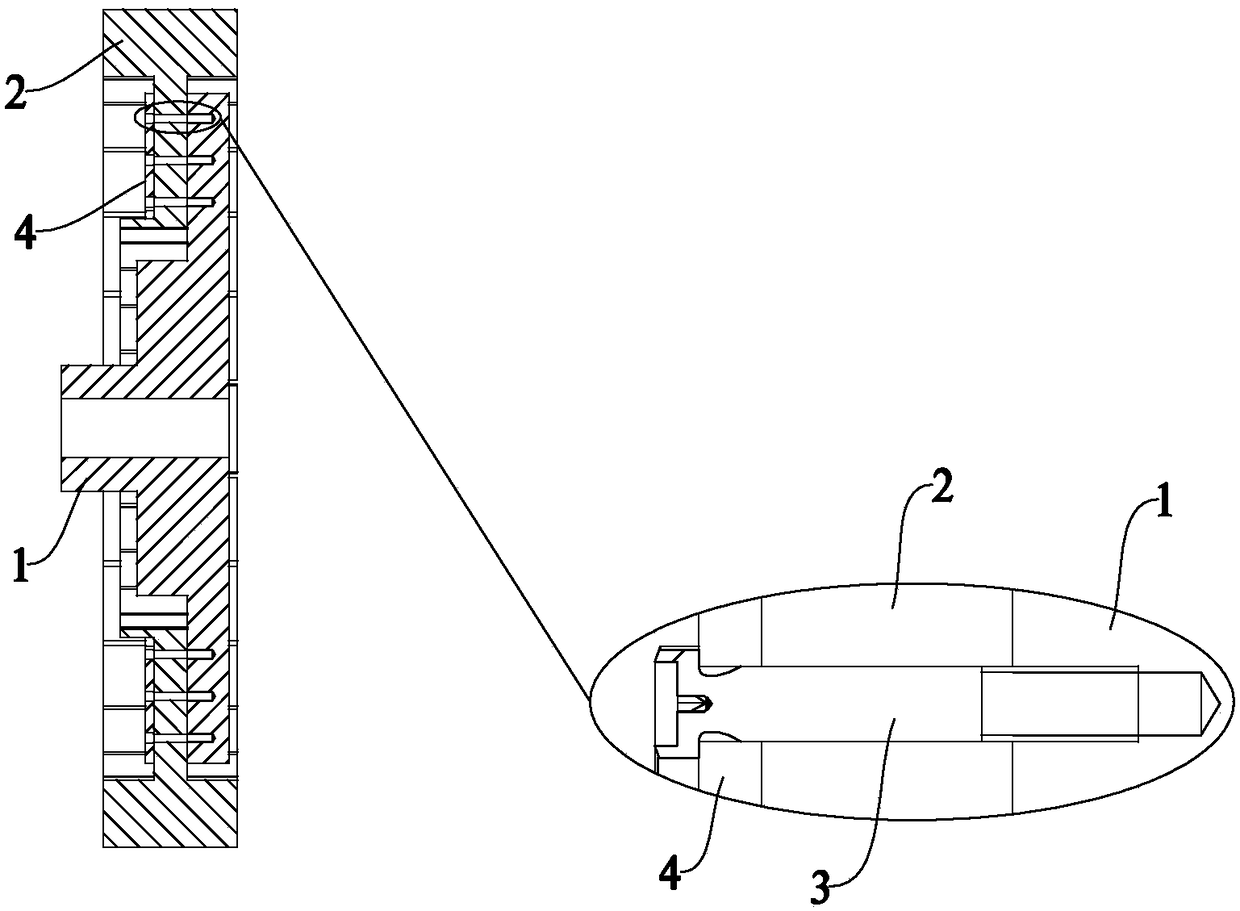

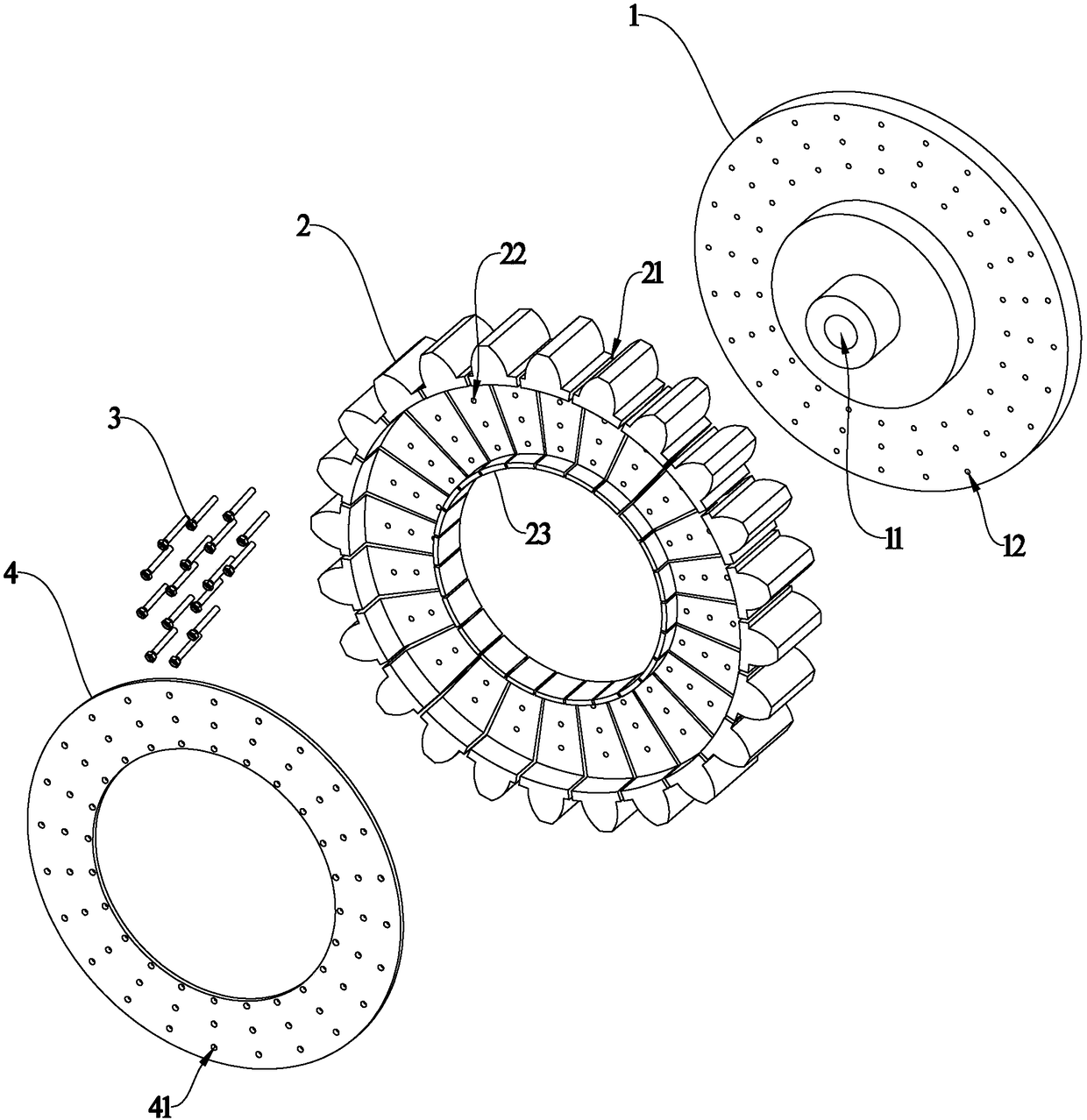

[0047] like Figures 1 to 8 As shown, the split gear 100 of a preferred embodiment of the present invention includes a gear base 1, a gear unit 2, a fixing bolt 3 and a connecting piece 4, the gear base 1 is provided with a shaft hole 11, and each gear unit 2 Corresponding to one tooth, a plurality of gear units 2 are evenly distributed on the gear base 1 along the circumferential direction, and there is an adjustment gap 21 between the gear units 2. The gear base 1 is provided with a threaded hole 12 which is matched with the fixing bolt 3. The unit 2 is provided with an adjustment hole 22. The adjustment hole 22 is slightly larger than the fixing bolt 3. The fixing bolt 3 passes through the adjustment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com