Auxiliary brake triple-safety device for beam-pumping unit

A beam pumping unit and auxiliary brake technology, applied in mechanical equipment, brake actuators, gear shifting mechanisms, etc., can solve problems such as inconvenience, danger, and potential safety hazards, and achieve easy operation, avoid vibration, Smooth and stable effect during operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings.

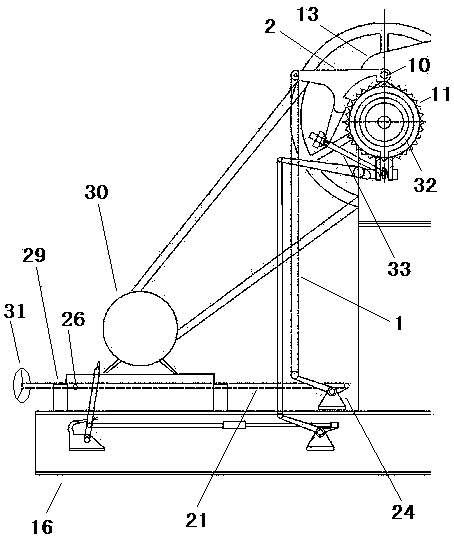

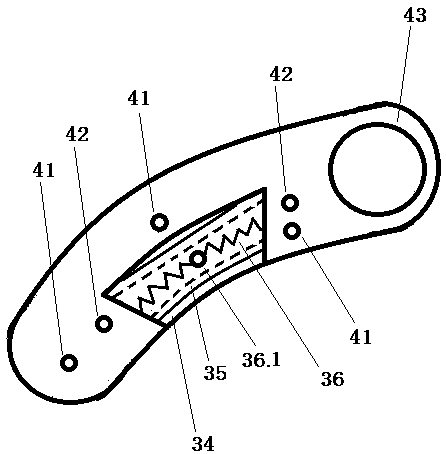

[0030] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 .

[0031] A triple safety device for auxiliary braking of a beam pumping unit includes a starting mechanism 29, an intermediate transmission mechanism, a first safety mechanism, a second safety mechanism and a third safety mechanism.

[0032] The starting mechanism 29 includes a bracket 23, a sleeve pipe 20, a bearing seat 18, a bearing, a drive shaft 22, a bolt transmission part and a manual rotating part. The lower part of the bracket 23 is welded on the pumping unit base 16, and the sleeve pipe 20 and the bearing seat 18 are connected in sequence and welded on the top of the bracket 23. In order to ensure the firmness of the bracket 23, the bracket 23 is welded by steel plates. Drive shaft 22 is installed on the bearing seat 18 by bearing, and the front end of dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com