Combined-type underwater hydraulic pump station

A hydraulic pump station and combined technology, applied in the field of hydraulic pump station, can solve the problems affecting the reliability of the operating system, high underwater failure rate, and many sensor transmission lines, achieve reliable sealing, reduce internal and external water pressure difference, The effect of improving sealing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

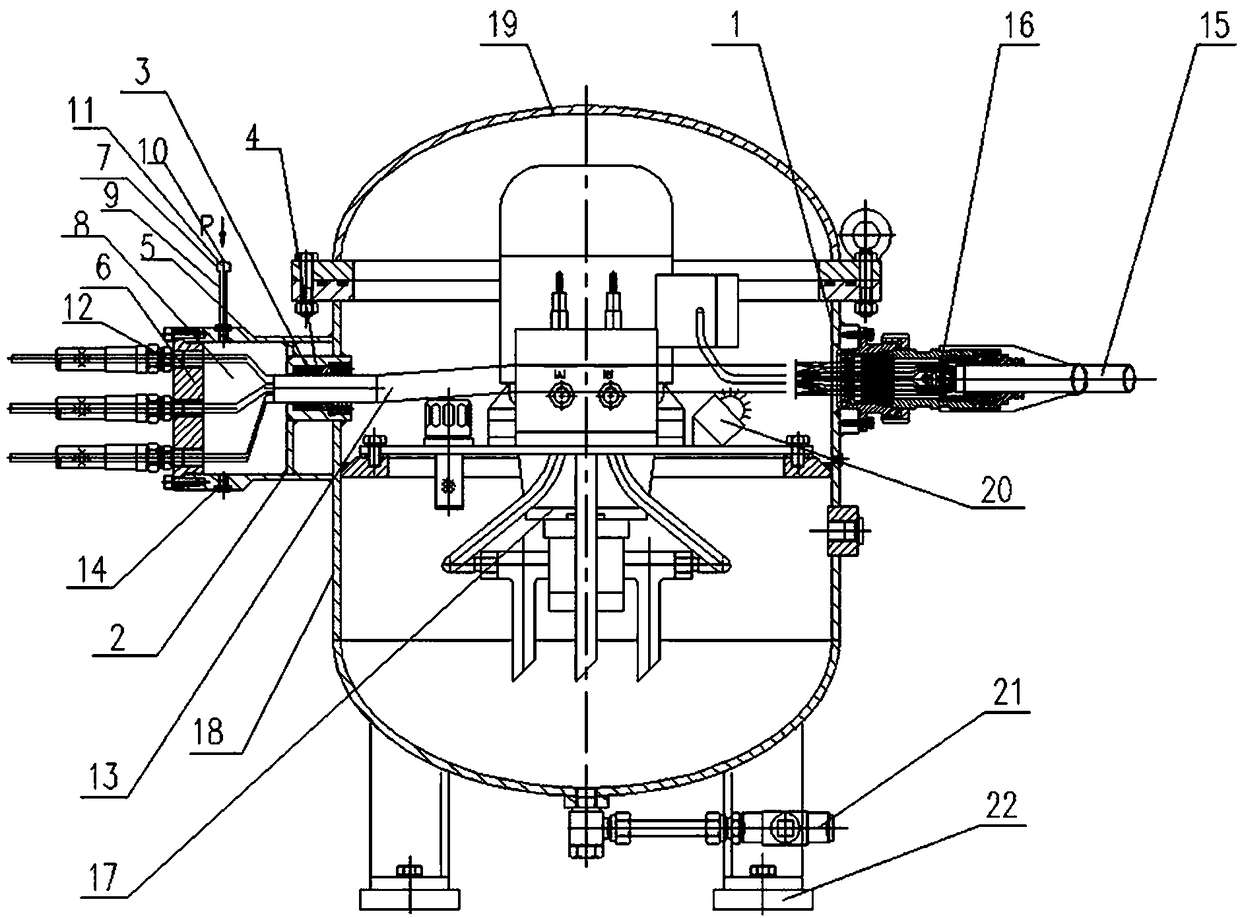

[0024] As a preferred embodiment of the application, refer to the attached figure 1 , this example discloses:

[0025] A combined underwater hydraulic pump station, including a pump station casing 1 and an intermediate junction box 2, the intermediate junction box 2 is welded on the pump station casing 1, and the pump station casing 1 and the intermediate junction box 2 are arranged There is a water-sealed joint seat mounting hole 4, and a water-sealed joint seat 3 is arranged in the water-sealed joint seat installation hole 4; the intermediate junction box 2 includes a box body 5 and an end cover welded as one with the pump station shell 1 6. The end cover 6 and the box body 5 are connected by bolts, the box body 5 is provided with a cavity 8, the intermediate junction box 2 is provided with a pressure equalizing mechanism 7, and the pressure equalizing mechanism 7 includes The connecting rod 9 and the elastic element 10, the connecting rod 9 is a hollow structure, one end o...

Embodiment 2

[0027] As a preferred embodiment of the application, refer to the attached figure 1 , this example discloses:

[0028] A combined underwater hydraulic pump station, including a pump station casing 1 and an intermediate junction box 2, the intermediate junction box 2 is welded on the pump station casing 1, and the pump station casing 1 and the intermediate junction box 2 are arranged There is a water-sealed joint seat mounting hole 4, and a water-sealed joint seat 3 is arranged in the water-sealed joint seat installation hole 4; the intermediate junction box 2 includes a box body 5 and an end cover welded as one with the pump station shell 1 6. The end cover 6 and the box body 5 are connected by bolts, the box body 5 is provided with a cavity 8, the intermediate junction box 2 is provided with a pressure equalizing mechanism 7, and the pressure equalizing mechanism 7 includes The connecting rod 9 and the elastic element 10, the connecting rod 9 is a hollow structure, one end o...

Embodiment 3

[0030] As a preferred embodiment of the application, refer to the attached figure 1 , this example discloses:

[0031]A combined underwater hydraulic pump station, including a pump station casing 1 and an intermediate junction box 2, the intermediate junction box 2 is welded on the pump station casing 1, and the pump station casing 1 and the intermediate junction box 2 are arranged There is a water-sealed joint seat mounting hole 4, and a water-sealed joint seat 3 is arranged in the water-sealed joint seat installation hole 4; the intermediate junction box 2 includes a box body 5 and an end cover welded as one with the pump station shell 1 6. The end cover 6 and the box body 5 are connected by bolts, the box body 5 is provided with a cavity 8, the intermediate junction box 2 is provided with a pressure equalizing mechanism 7, and the pressure equalizing mechanism 7 includes The connecting rod 9 and the elastic element 10, the connecting rod 9 is a hollow structure, one end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com