Wall tie piece assembly capable of eliminating construction error

A technology of construction errors and components, applied in the field of components, can solve the problems of weakening the area and diameter of the wire end of the wall ties, failure to play, and inaccurate positions, etc., and achieve smooth vibration, increased interlocking force, and reduced length Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

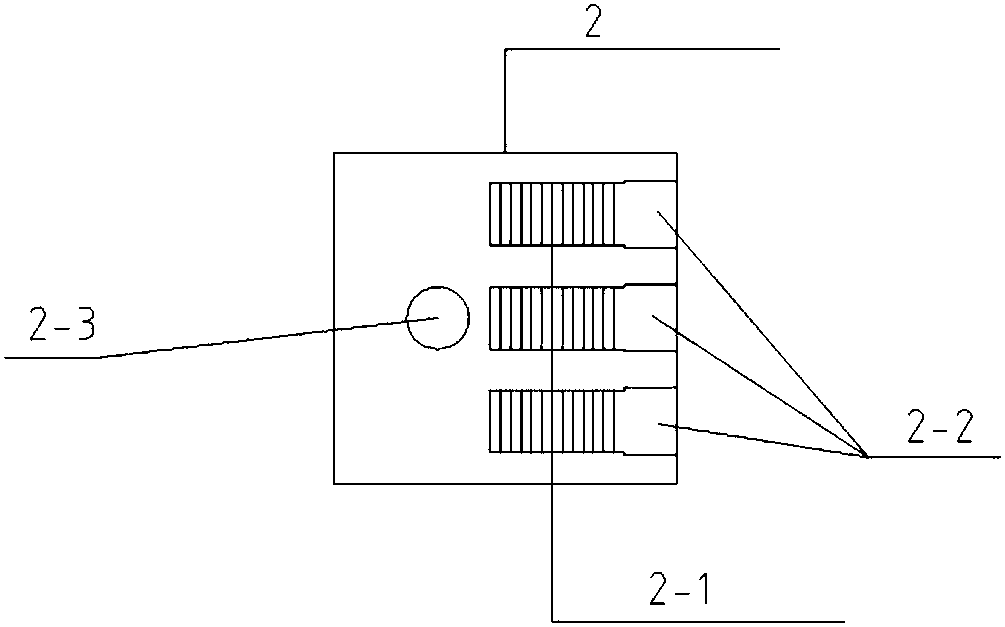

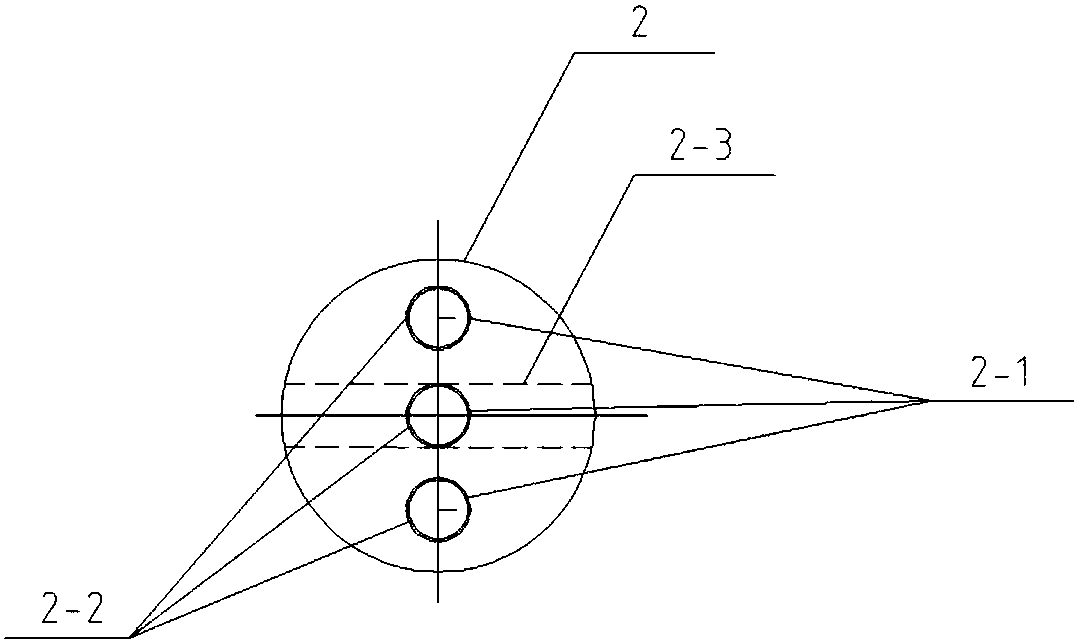

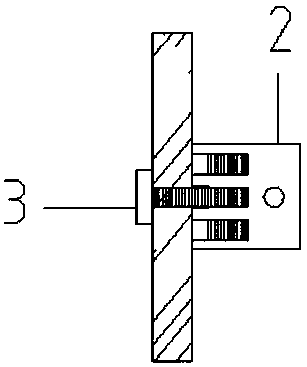

[0020] As shown in the figure, a wall tie bar assembly for eliminating construction errors of the present invention includes an inner threaded part 2 pre-embedded in the concrete along the direction perpendicular to the concrete facade to be poured, in the inner threaded part 2 There are three blind holes along the axial direction of the inner threaded part. The axial direction of the inner threaded part is perpendicular to the direction of the concrete facade to be poured. The axis of one blind hole is located on the central axis of the inner threaded part 2 , the axes of the other two blind holes are arranged symmetrically on the upper and lower sides of the central axis of the inner thread member 2, and the walls of the three blind holes are arranged in sequence from the outside to the inside as the light hole 2-2 and the light hole The co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com