A system for removing VOC from polypropylene pellets and its application method

A polypropylene granule and control system technology, applied in the direction of coating, etc., can solve the problems of reducing safety and applicability, and achieve the effect of reliable performance, low investment and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

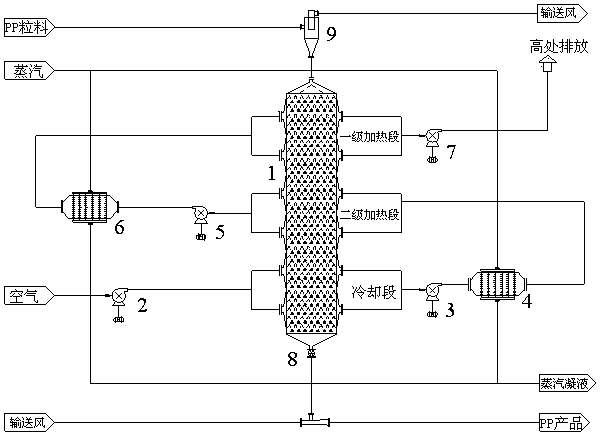

[0025] Such as figure 1 As shown, a system for removing VOC from polypropylene pellets, the system includes a roof-mounted devolatilization tower 1 with a weighing control system, a cyclone dust collector 9, a primary heater 6 and a secondary heater 4.

[0026] The top of the roof-type devolatilization tower 1 is provided with a material inlet, and the bottom is provided with a rotary unloading valve 8 with a speed change device; the material inlet is connected with the cyclone dust collector 9; one side of the roof-type devolatilization tower 1 is sequentially arranged from top to bottom There are primary air inlets, secondary air outlets, and cooling air inlets, and the other side is provided with primary air outlets, secondary air inlets, and cooling air outlets from top to bottom; the primary air inlets are passed through the primary heater 6, Circulation fan Ⅱ5 is connected to the secondary air outlet; the cooling air inlet is connected to the ambient air input pipe throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com