Automobile component machining equipment

A technology of auto parts and processing equipment, which is applied in the field of parts processing, can solve the problems of low grinding efficiency, long grinding time, and increased dust volume, and achieve the effect of convenient grinding and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

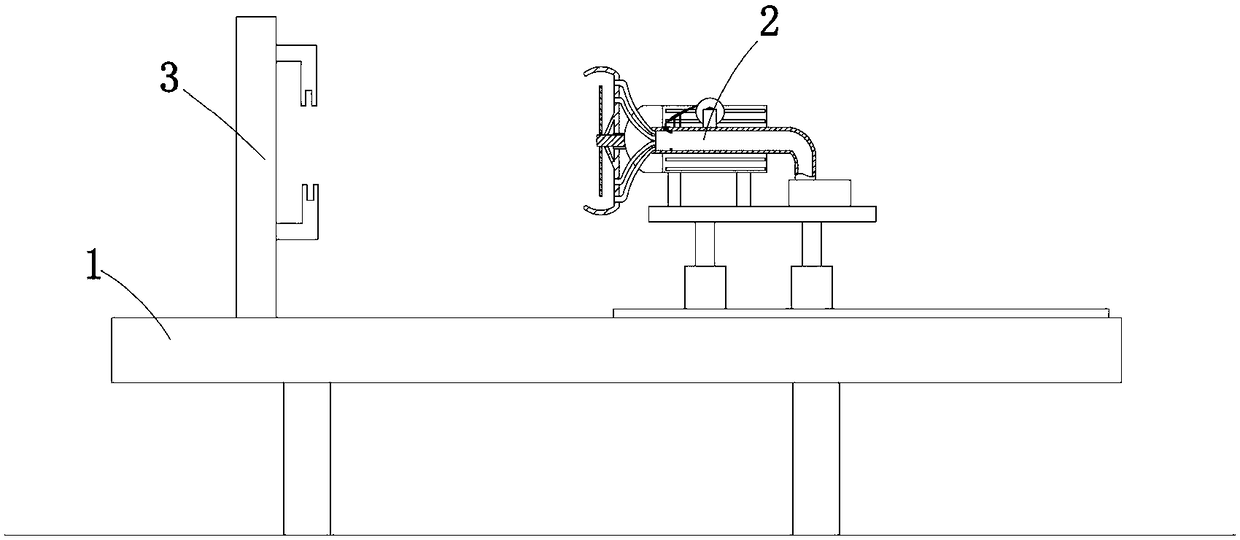

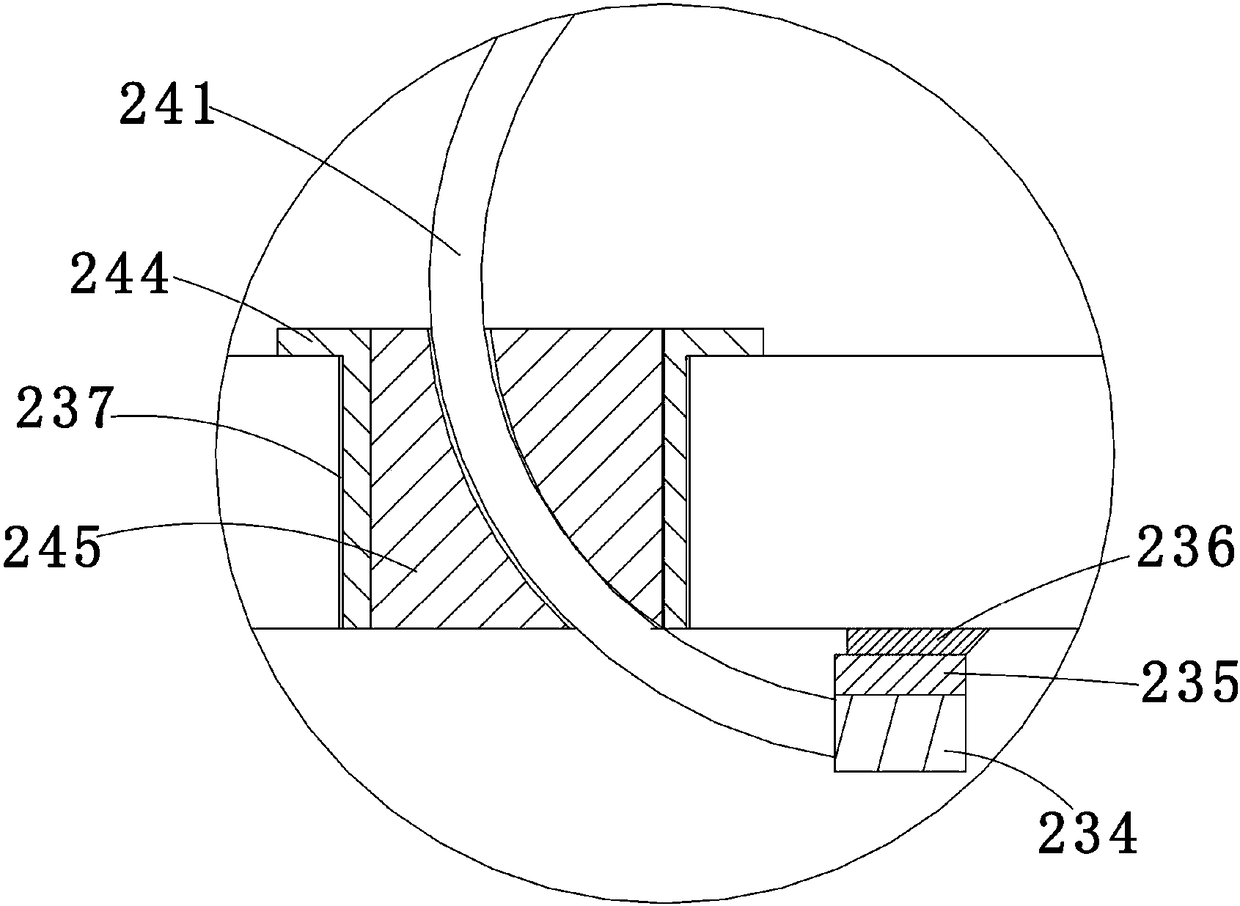

[0020] Such as Figure 1-5 As shown, a kind of auto parts processing equipment includes a workbench 1, a grinding device 2 and a fixing device 3; Mechanical grasping; after the workpiece to be processed is fixed on the fixing device 3, the workpiece is processed and polished by the grinding device 2; specifically, the grinding device 2 includes a grinding part 21, a driving part 22 and a dust removal structure 23; wherein the grinding part 21 is a sand disc, and the driving part 22 is a motor, and the output shaft of the driving part 22 is detachably connected with the grinding part 21. When the driving part 22 is working, the grinding part 21 rotates at a high speed and quic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com