Paint brushing device for two faces of cork board

A cork board, double-sided technology, which is applied to devices and coatings that apply liquid to the surface, can solve the problems of large size of cork boards, waste of labor resources, difficulty in turning over by one person, etc., achieving simple operation and saving time and cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following is further described in detail through specific implementation methods:

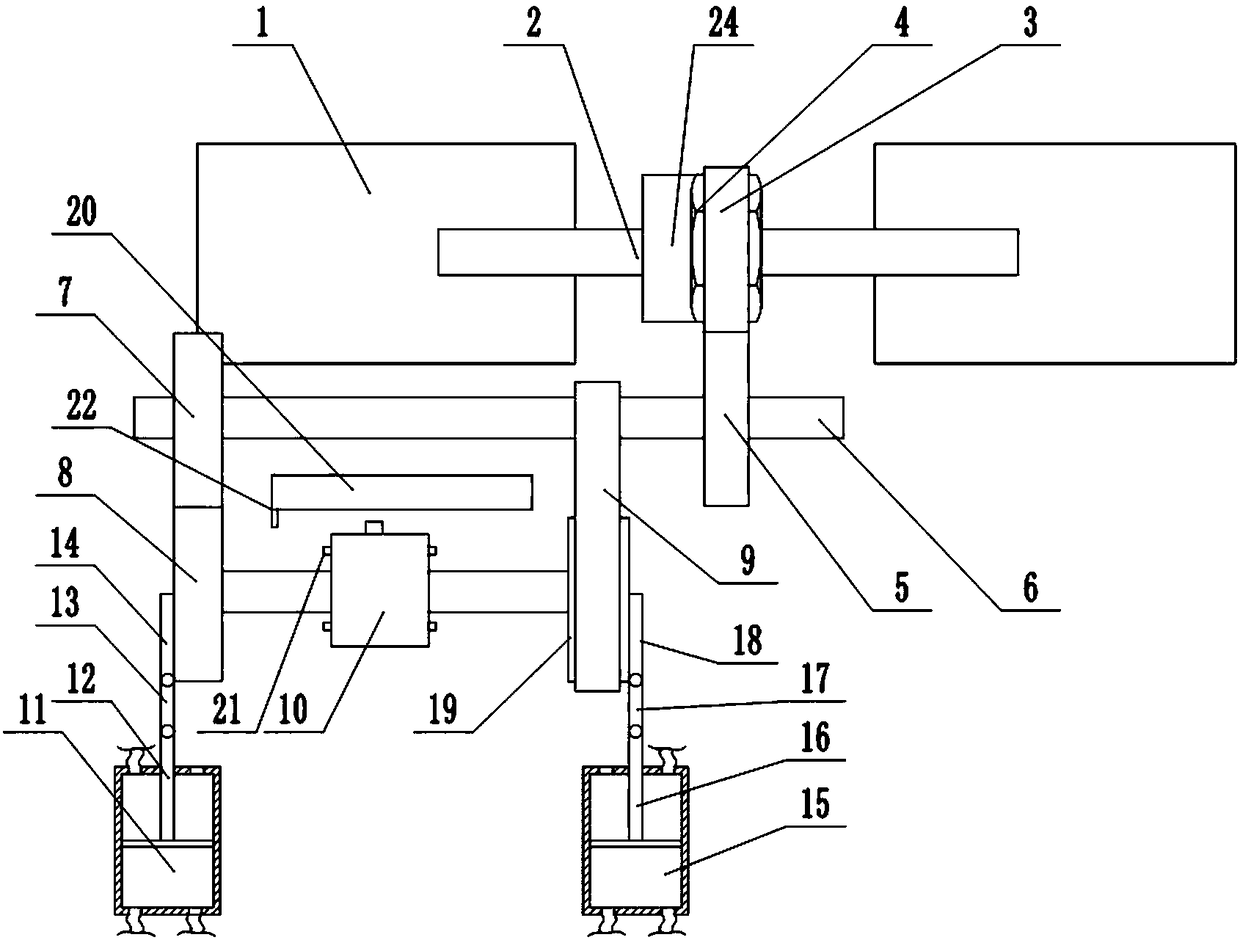

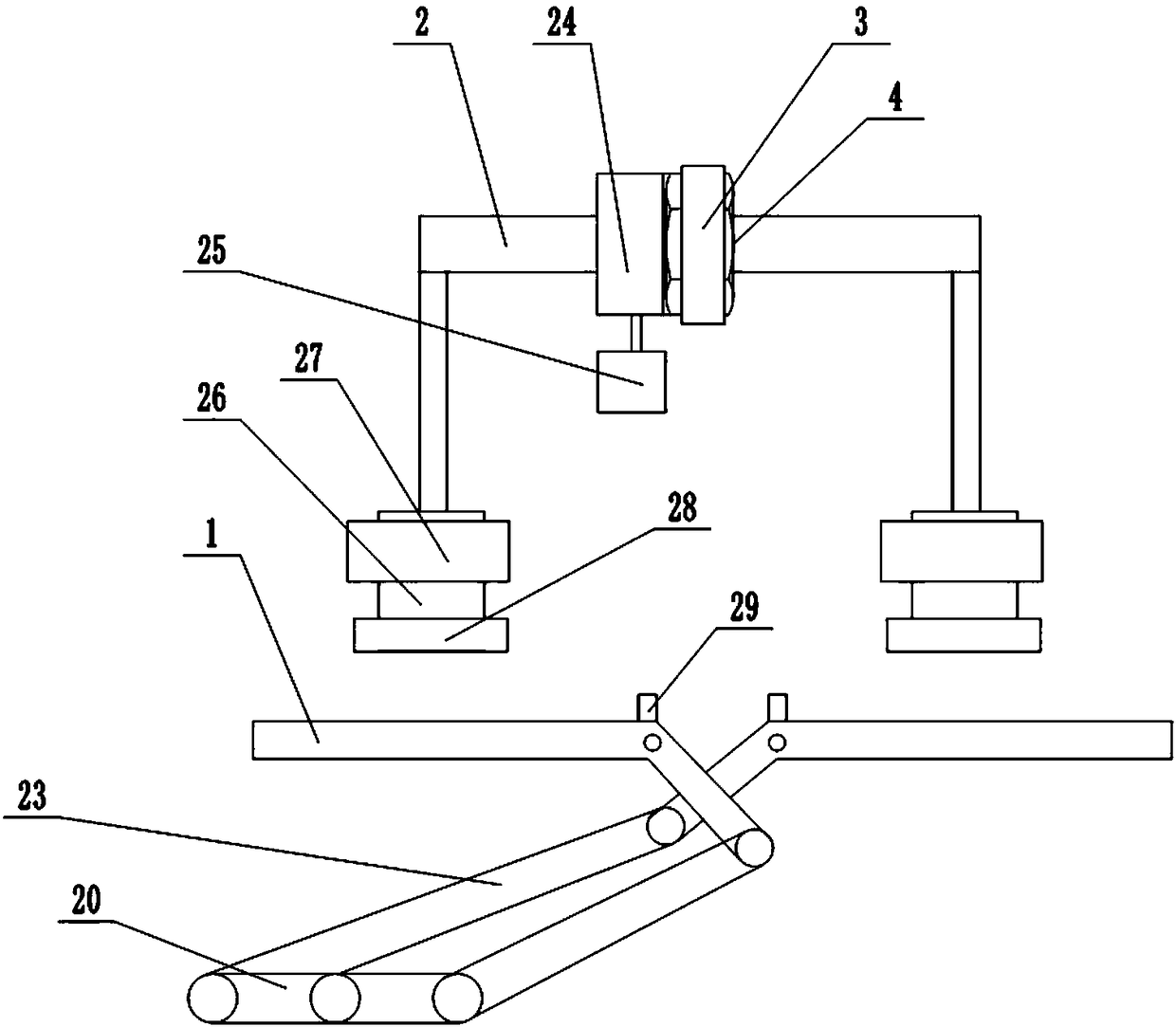

[0023] The reference numerals in the accompanying drawings of the description include: flip plate 1, screw mandrel 2, fourth gear 3, nut 4, third gear 5, second rotating shaft 6, second gear 7, first gear 8, belt 9, engaging Set 10, first piston barrel 11, first piston rod 12, second connecting rod 13, third connecting rod 14, second piston barrel 15, second piston rod 16, fourth connecting rod 17, fifth connecting rod 18 , Disc 19, handle 20, limit block 21, lever 22, first connecting rod 23, first sleeve 24, hydraulic cylinder 25, second sleeve 26, fifth gear 27, sponge brush head 28.

[0024] like figure 1 As shown, the cork board double-sided painting device includes a frame, and the frame is provided with a painting part, a turning part and a driving part, and the turning part is located below the painting part.

[0025] like figure 2 As shown, the turning part includes a ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com