Multifunctional organic fertilizer processing equipment

A processing equipment and organic fertilizer technology, applied in the field of multifunctional organic fertilizer processing equipment, can solve the problems of uneven crushing, easy accumulation of raw materials, and low crushing efficiency, and achieve the effects of improving crushing quality, keeping clean, and saving equipment energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Further detailed explanation through specific implementation mode below:

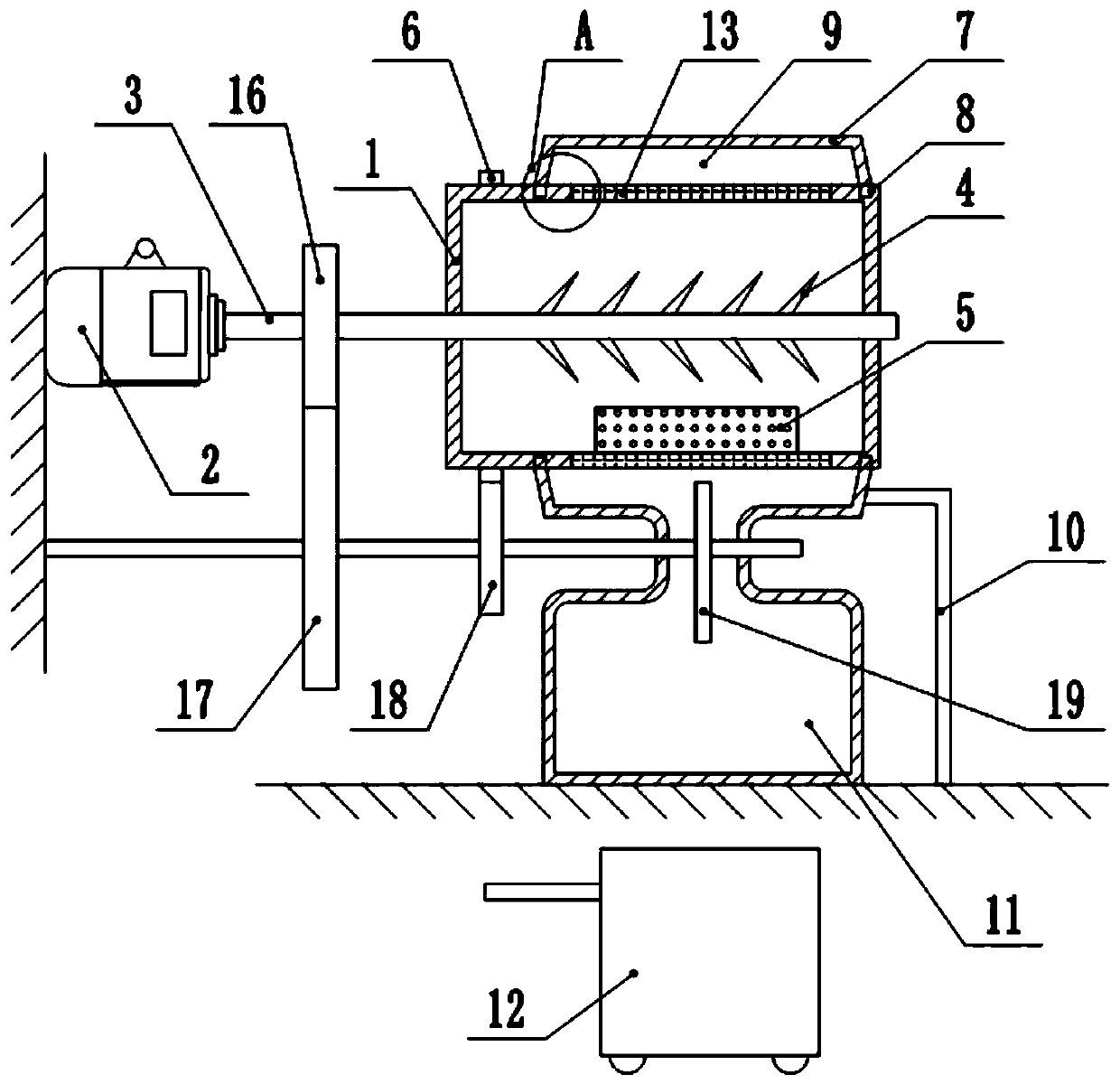

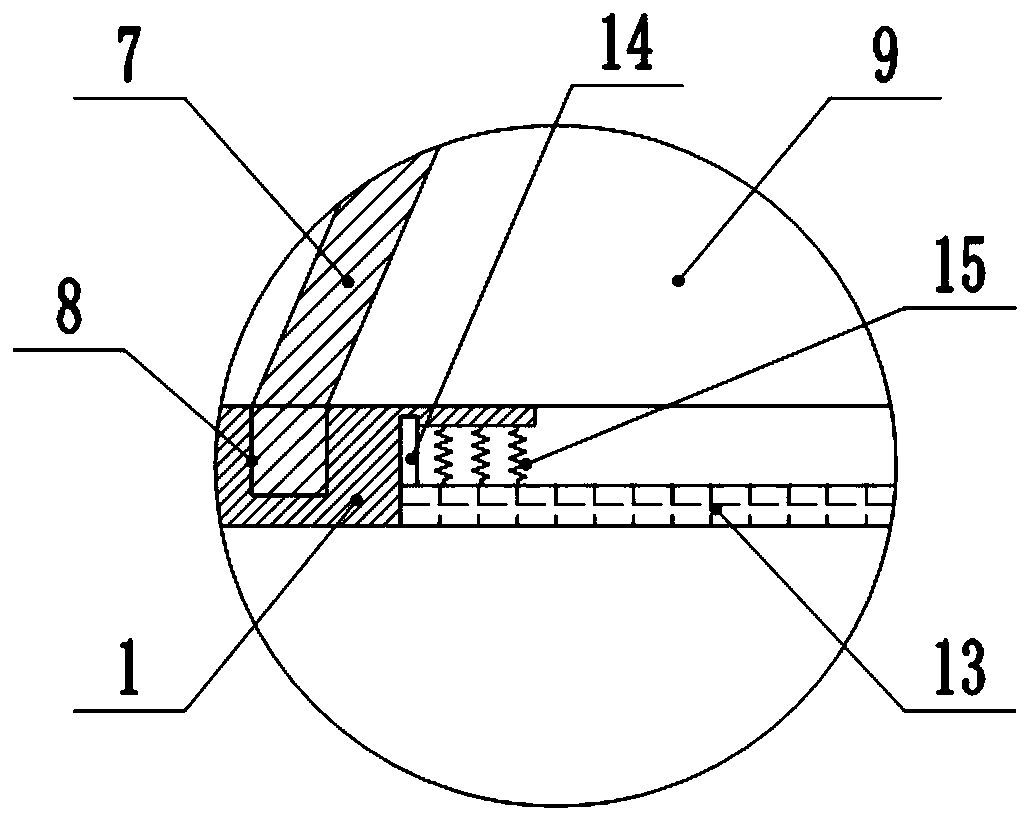

[0019] The reference signs in the drawings of the description include: crushing tank 1, motor 2, rotating shaft 3, cutter 4, partition 5, ring gear 6, cylinder 7, first chute 8, annular chamber 9, strut 10, Sediment tank 11, transport trolley 12, circular screen 13, second chute 14, spring 15, first gear 16, second gear 17, third gear 18, cam 19.

[0020] This embodiment is basically as figure 1 As shown, the multi-functional organic fertilizer processing equipment includes a frame and a crushing tank 1, a motor 2 is fixedly installed on the frame, and the output end of the motor 2 is fixedly connected with a rotating shaft 3, and the rotating shaft 3 runs through the opposite left wall of the crushing tank 1 and The right wall is arranged, the rotating shaft 3 is rotationally connected with the side wall of the crushing tank 1, the joint between the rotating shaft 3 and the crushing tank 1 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com