Atomization spray gun for SNCR (Selective Non-Catalytic Reduction) denitration system and application of atomization spray gun

An atomization spray gun and denitrification technology, which is applied in the direction of injection devices, liquid injection devices, chemical instruments and methods, etc., can solve the problems of complex structure, spray liquid blockage, etc., and achieve the effect of simple adjustment, uniform atomization and firm structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment, further illustrate the present invention, should understand that following specific embodiment is only for illustrating the present invention and is not intended to limit the scope of the present invention, after having read the present invention, those skilled in the art will understand the present invention Modifications in various equivalent forms fall within the scope defined by the appended claims of the present application.

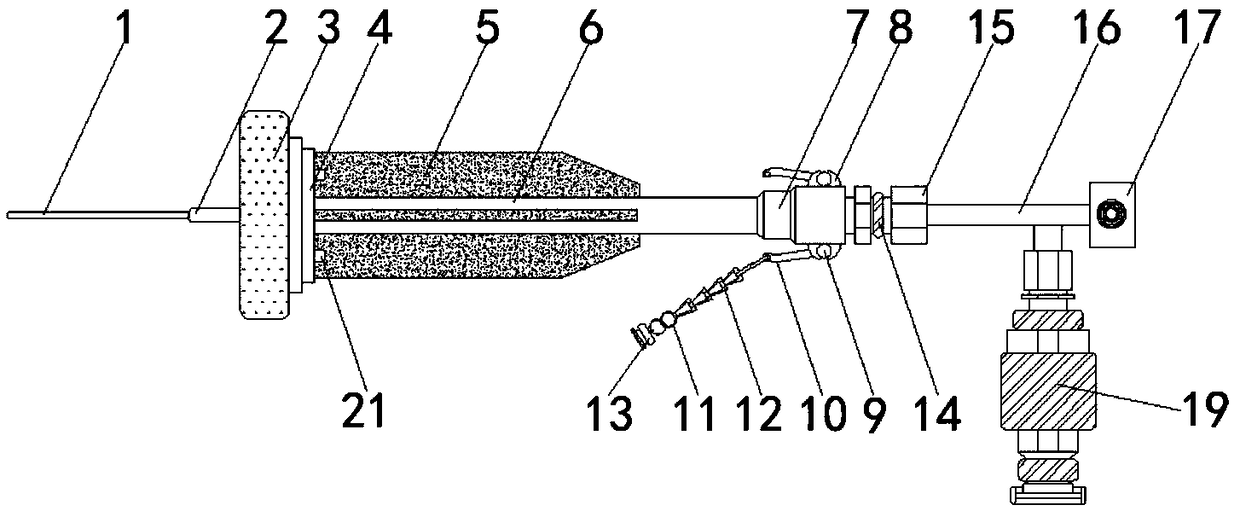

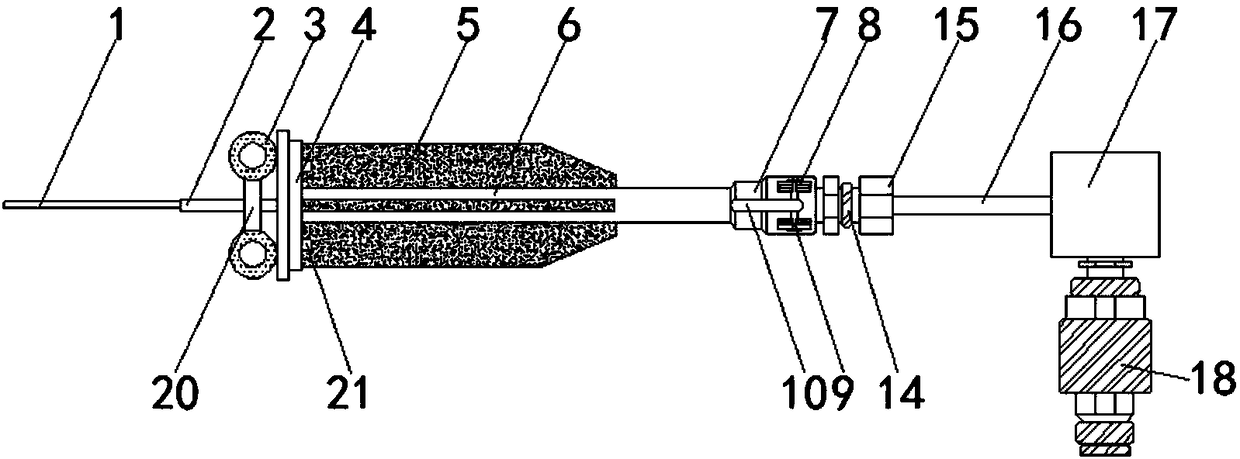

[0020] see Figure 1-2 , an atomizing spray gun for an SNCR denitrification system, including an injection pipe 1, the right side of the injection pipe 1 runs through the end protection pipe 2, the connecting plate 20 and the fixing plate 4 and extends to the inside of the mixing chamber 6, and the outside of the injection pipe 1 The terminal protection tube 2 is fixedly connected, the terminal protection tube 2 runs through the connection plate 20 and extends to the insi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com