Deodorant based on plant essence extracting solution and preparation method of deodorant

A plant essence and deodorant technology, applied in the fields of botanical equipment and methods, plant growth regulators, separation methods, etc., can solve the problems of lack of effective removal of carcinogenic gases, low purity of active ingredients, poor effect, etc., to reduce bacteria. The speed of reproduction, the effect is thorough, and the effect of not polluting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A plant essence extract deodorant, its preparation method is as follows:

[0035] (1) Weigh 1.5% laurate, 1.0% tea polyphenols, 0.5% rhodamine, 1.0% citronellol, 0.2% pinene, 1.1% linalool, 0.5% terpineol, limonene by weight percentage 0.6%, eucalyptol 1.3%, L-camphor 0.8%, menthol 0.2%, 4-terpene alcohol 0.9%, terpineol 0.7%, carvone 0.5%, isobornyl acetate 0.5%, cedrene 0.3%, thujene 0.5%, thujene 0.1%, cedene 0.5%, purified water 87.30%.

[0036] (2) Put pure water into the reaction kettle and heat to 40-50°C;

[0037] (3) add laurate, stir until it dissolves completely;

[0038] (4) Add the remaining components and continue to stir until a clear and transparent solution is obtained;

[0039] (5) Stop stirring, and obtain a stable clear and transparent solution after standing for 20 minutes, which is the deodorant of the present embodiment 1.

Embodiment 2-4

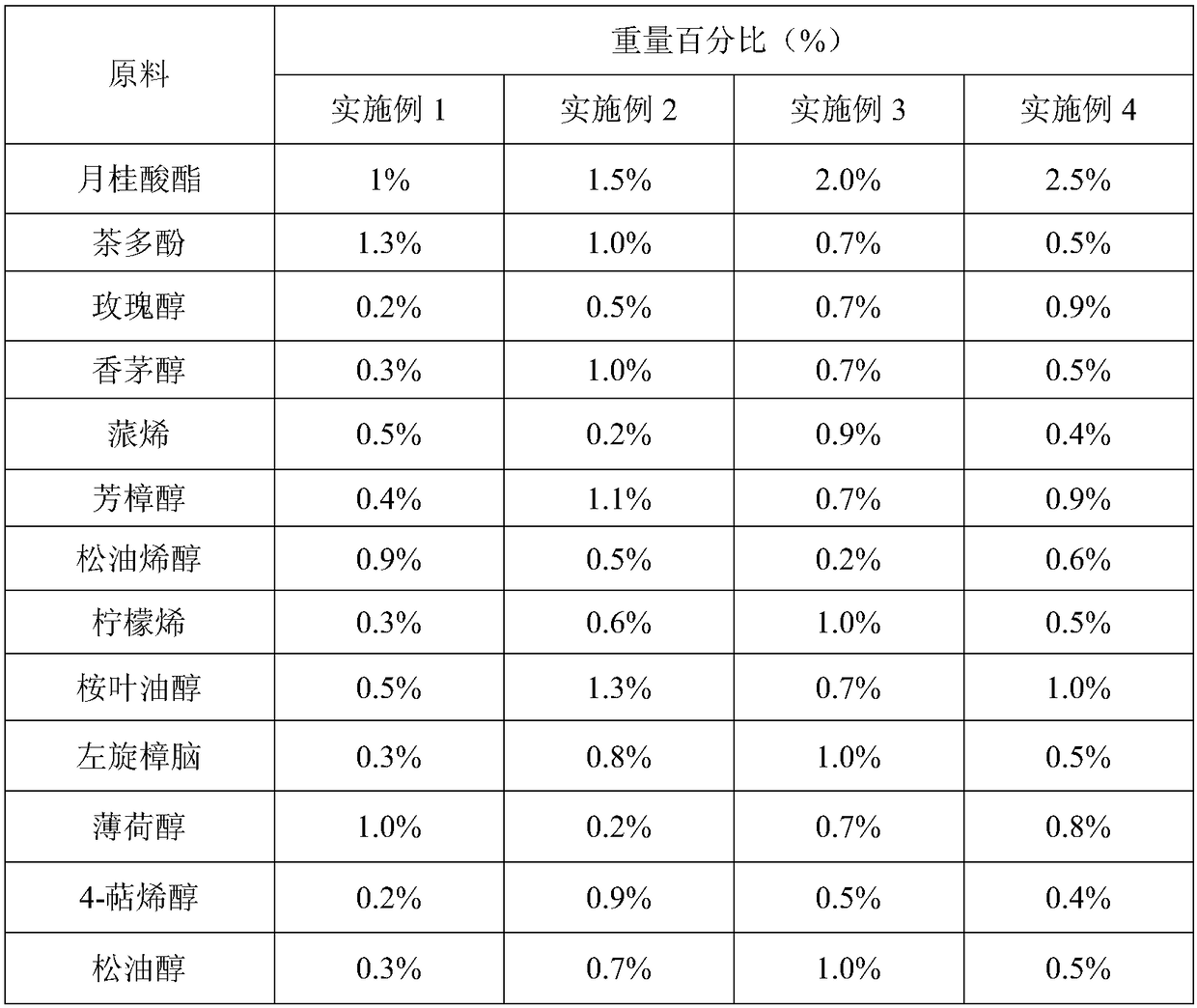

[0040] The rest of Examples 2-4 were prepared in the same way as Example 1 by comparing the raw materials and weight percentages of the corresponding examples in Table 1 below.

[0041] Table 1 embodiment 1-4 each raw material and weight percentage thereof

[0042]

[0043]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com