Unsalted butter granular essence and preparation method thereof

A technique for whipping cream and granules, which is applied to the field of whipped cream granule essence and its preparation, can solve the problems of thin aroma and harsh storage conditions of whipped cream, and achieve the effects of realistic taste, mellow and rich aroma, and improvement of insufficient aroma.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0036] This embodiment mainly analyzes the influence of the enzymolysis temperature on the aroma of the reaction product through experiments.

[0037] The temperature of the enzymolysis reaction was explored through Examples 1-3, and the influence of different reaction temperatures on the aroma of the reaction product was obtained. The specific results are shown in Table 1.

[0038] Table 1 Effects of different enzymatic hydrolysis temperatures on the aroma of the reaction product

[0039] raw material

[0040] It can be seen from Table 1 that when the temperature of the enzymolysis reaction in Example 1 is controlled at 45°C, the light cream granule essence prepared in Example 1 is added to 4wt% of the milk powder aqueous solution, and the addition amount is 1wt% of the milk powder aqueous solution. After tasting, the teacher found that the aroma was relatively pure, but the aroma was weak and the mouthfeel was thin; when the temperature of the enzymolysis reaction ...

Embodiment 4~7

[0042] Examples 4-7 mainly analyze the influence of enzymatic hydrolysis time on the aroma of the reaction product through experiments.

[0043] The enzymatic hydrolysis reaction time was explored, and the influence of different reaction time on the aroma of the reaction product was obtained. The results are shown in Table 2.

[0044] Table 2 Effects of different enzymatic hydrolysis times on the aroma of the reaction product

[0045] raw material

[0046] It can be seen from Table 2 that when the enzymolysis reaction time in Example 4 is controlled at 1 hour, the product is added to 4wt% milk powder aqueous solution, and the addition amount is 1wt% of the milk powder aqueous solution. After tasted by the perfumer, it is found that the aroma is relatively pure , but the aroma is weak, and there is a sense of roughness; when the enzymolysis reaction time is controlled at 2h in Example 5, by tasting, it feels that the aroma and mouthfeel are all improved compared with ...

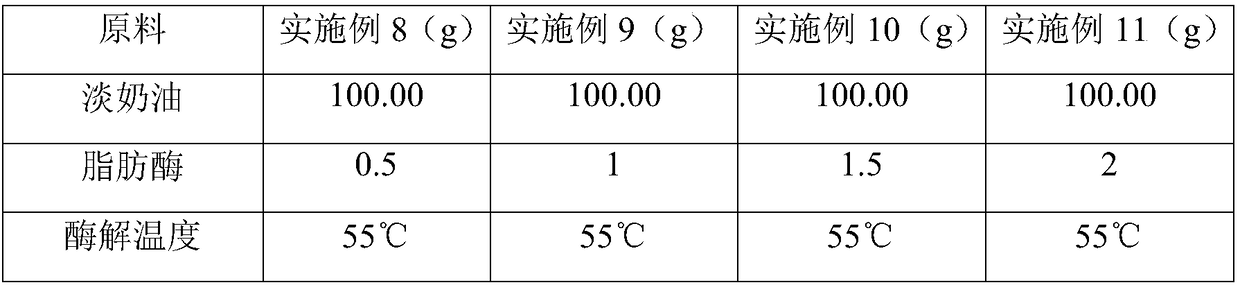

Embodiment 8~11

[0048] Examples 8-11 analyzed the influence of different lipase dosages on the aroma of the reaction product.

[0049] The amount of lipase was explored, and the effect of different lipase amounts on the aroma of the reaction product was obtained. The results are shown in Table 3.

[0050] The impact of the amount of different lipases in table 3 on the aroma of the reaction product

[0051]

[0052]

[0053] As can be seen from Table 3, the mass ratio of whipping cream and lipase consumption is controlled at about 100:0.5 in embodiment 8, by adding the product in the milk powder aqueous solution of 4wt%, the addition is 1wt% of described milk powder aqueous solution, after adjusting After tasting, the perfumer found that the aroma of milk is not strong enough, the taste is not full enough, and it is slightly grainy; the mass ratio of whipped cream and lipase in formula 9 is controlled at about 100:1. After tasting, the aroma of milk is relatively strong , the fullness and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com