Energy feedback-based permanent-magnet speed regulation device

An energy feedback, permanent magnet speed regulation technology, which is applied to electromechanical devices, permanent magnet clutches/brakes, asynchronous induction clutches/brakes, etc. Speed system transmission shaft wear, large footprint and other issues, to achieve the effect of solving the large footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

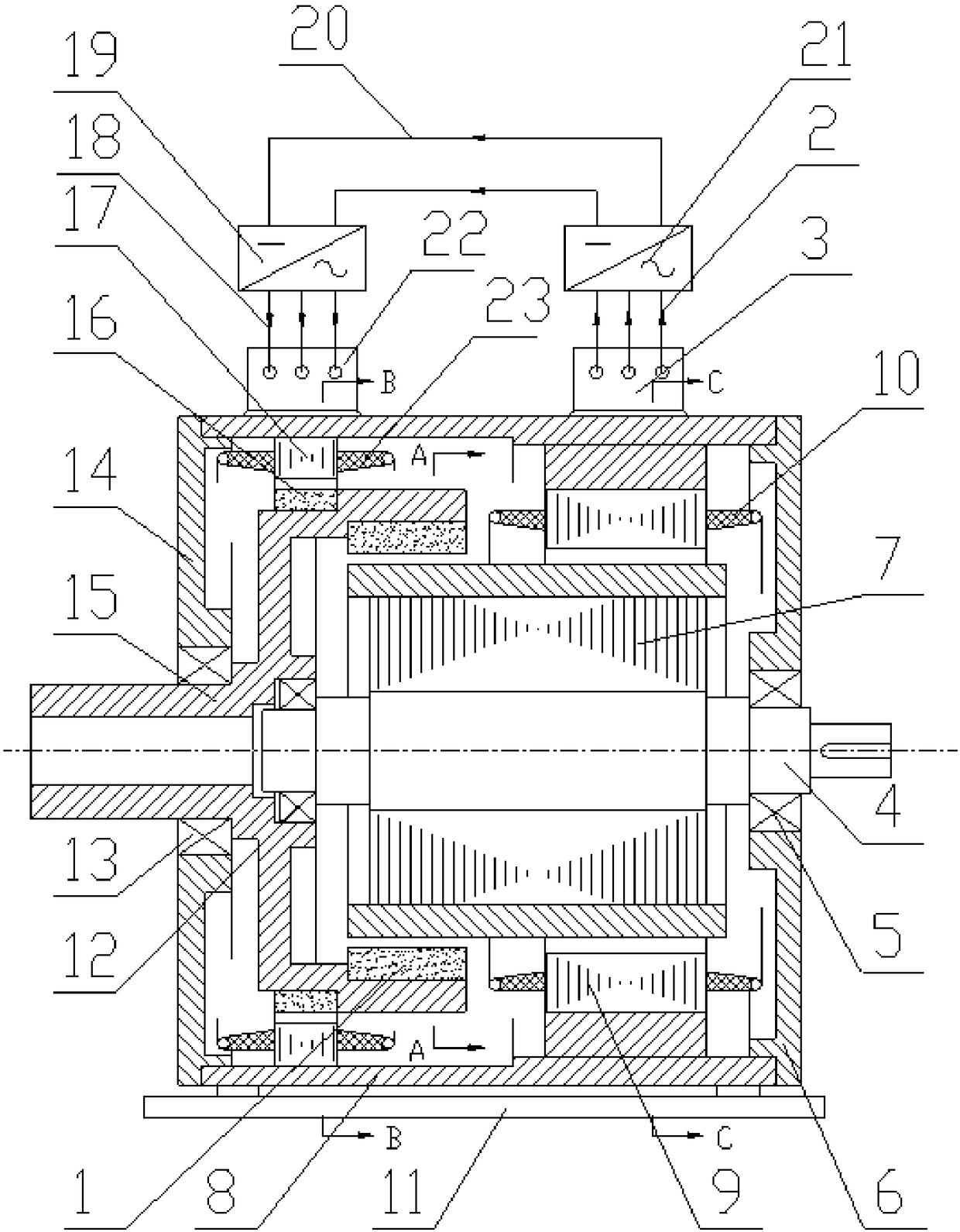

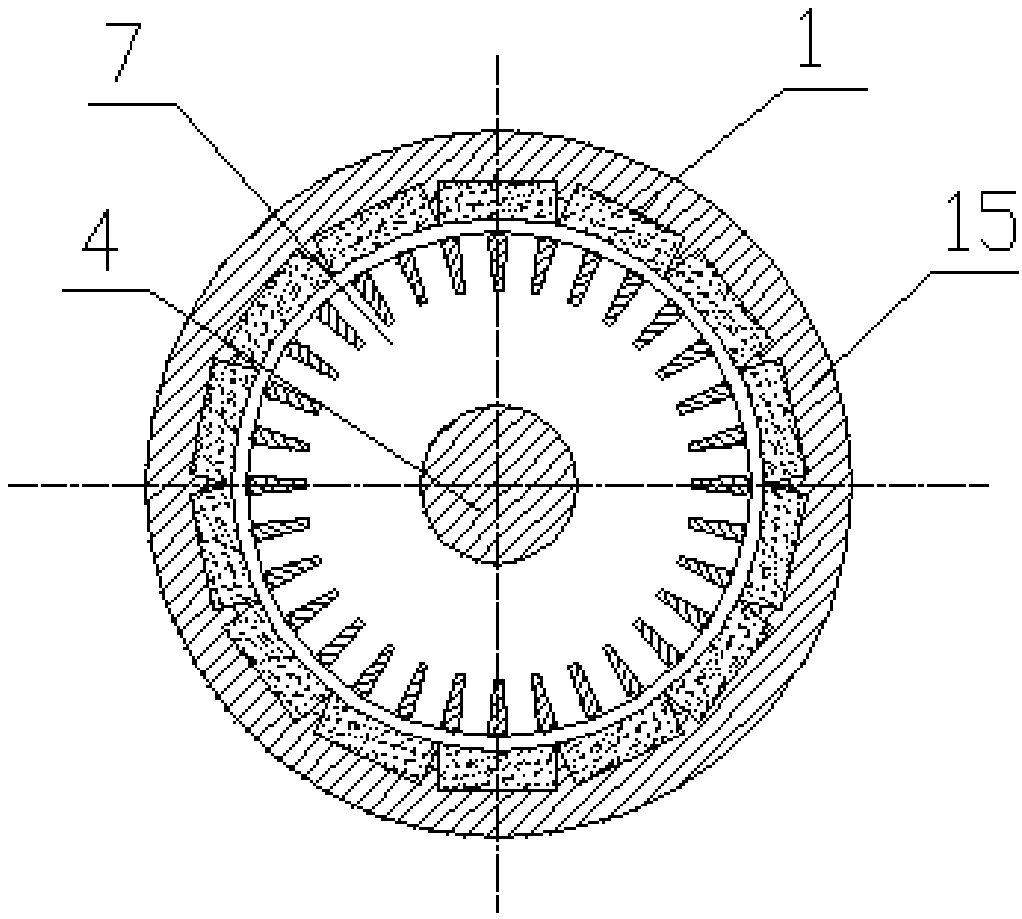

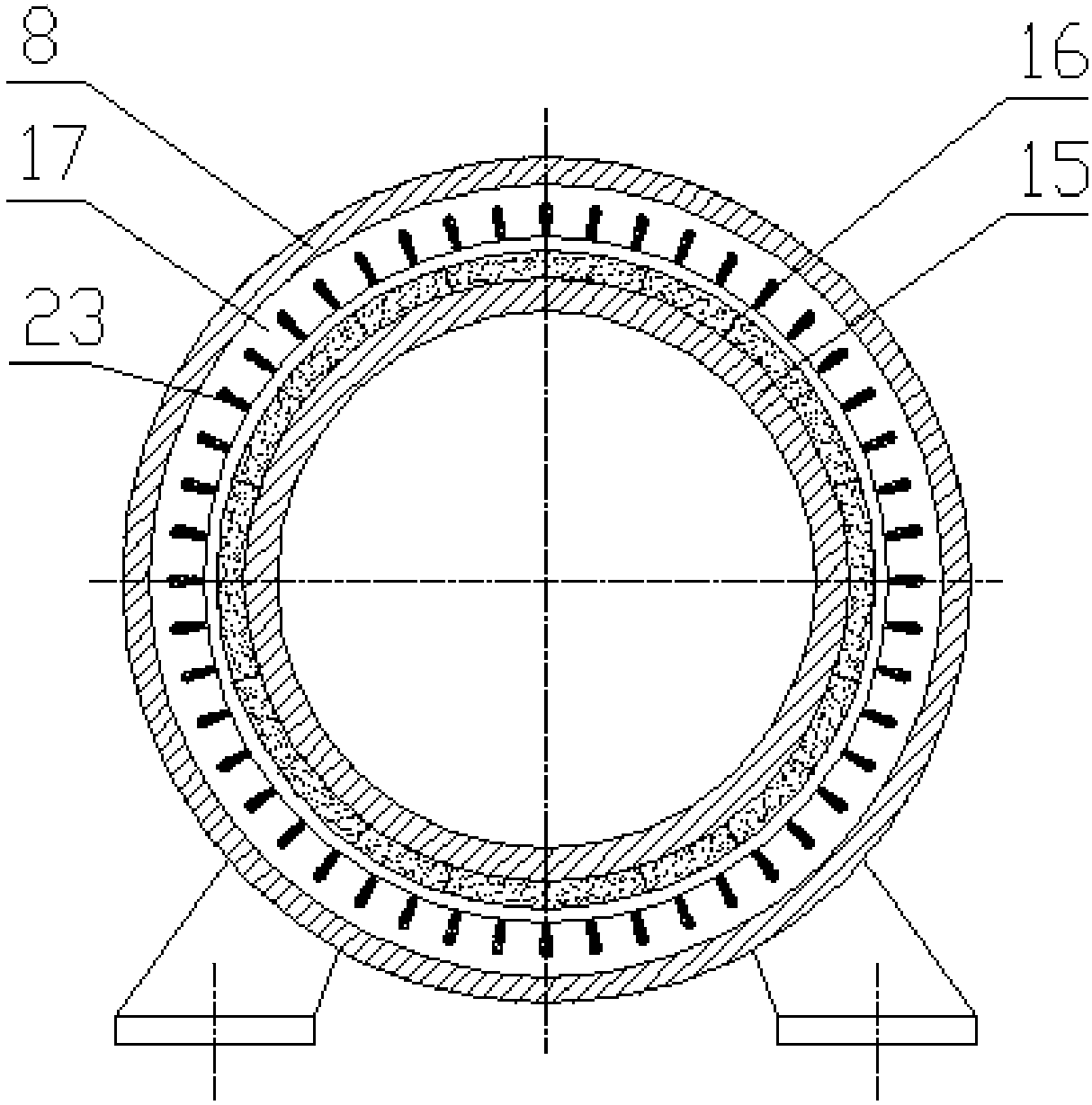

[0027] The present invention will be further described below in conjunction with accompanying drawing, as Figure 1-4 As shown, based on the energy feedback type permanent magnet speed control device, it includes an outer rotor assembly, an inner rotor assembly, an energy feedback device assembly and a base assembly; the outer rotor assembly includes permanent magnets I1, permanent magnets II16 , embedded bearing 12 and power input shaft 15; described inner rotor assembly includes inner rotor coil winding 7 and power output shaft 4; described energy feedback device assembly includes stator yoke iron I9, stator coil I10, shell body 8, outlet box 3, stator winding outlet 2, inverter I21, cable 20, inverter II19, stator winding inlet 18 and inlet box 22; the base assembly includes a bottom plate 11, a left end bearing end Cover 14, left end bearing 13, right end bearing end cover 6 and right end bearing 5.

[0028] The permanent magnet I1 is installed on the largest inner surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com