An alcohol fuel cell system

A fuel cell system and fuel cell stack technology, applied in fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve problems such as low system efficiency and low fuel recovery rate, save heat dissipation space, and avoid replacement. Thermal equipment or heat exchange energy consumption, the effect of improving fuel utilization and system efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

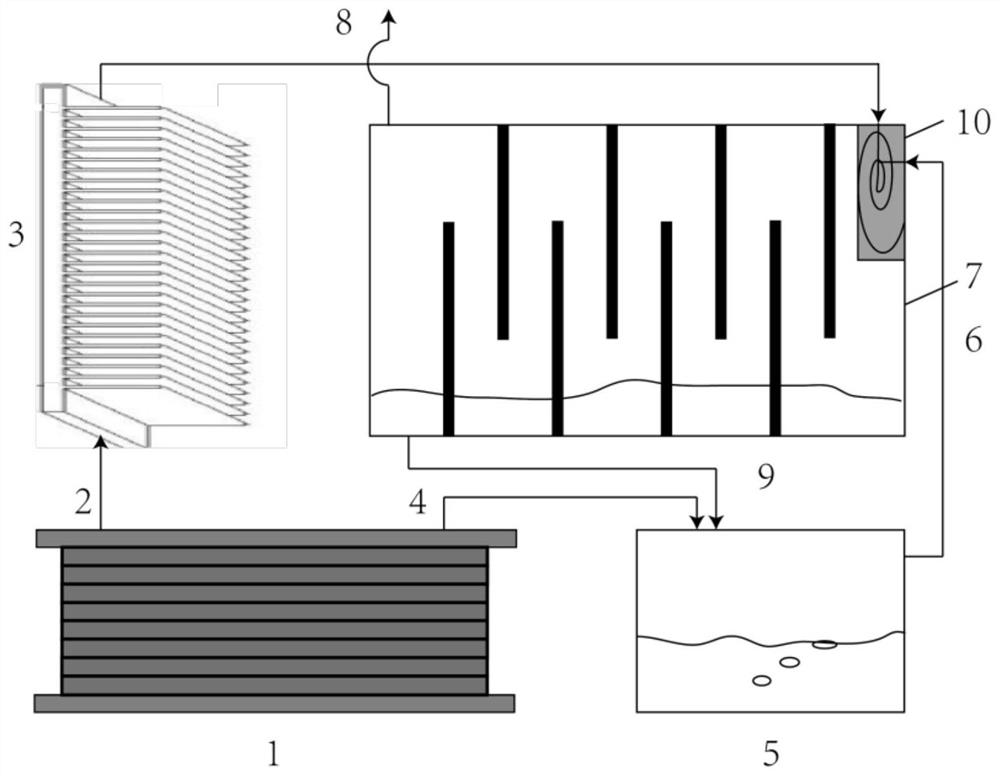

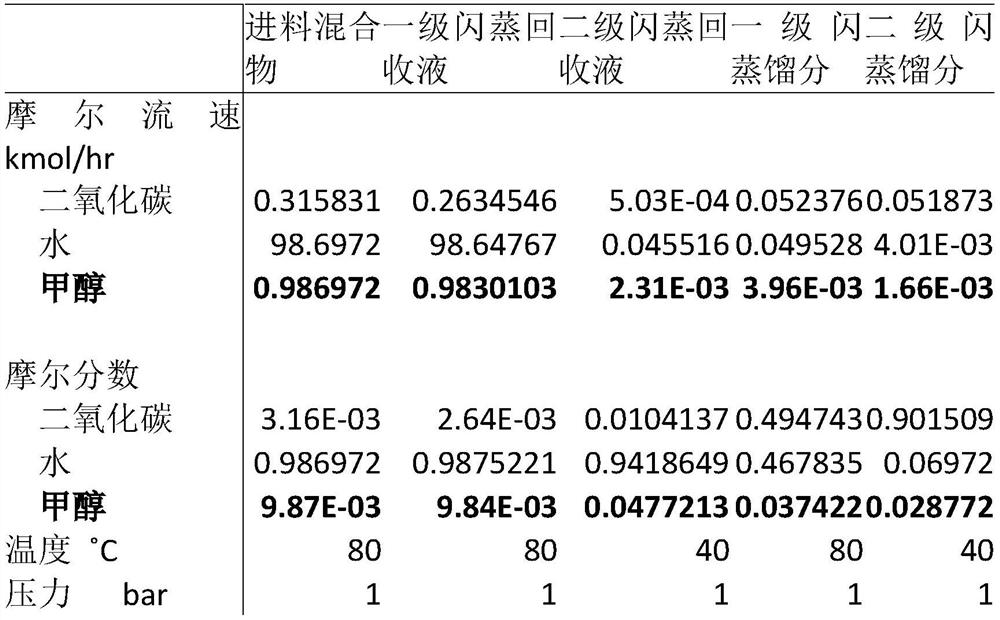

[0023] CO produced by stack anode 2 After the gas passes through the gravity separation of the 5 liquid storage tanks, the gaseous CO 2 Carrying saturated water vapor into the contactor 10 in the gas-liquid separator 7 at a flow rate of 1-20L / min, and meeting the air tail gas with a flow rate of 1-100L / min generated by the cathode of the stack and cooled by the radiator, the two Substance and heat exchange is fully carried out in 10 contactors. CO after heat and mass exchange 2 The steam methanol in the vapor is cooled to a liquid state at a temperature of 50-20 degrees Celsius, and is trapped in 7 gas-liquid separators. The loss rate of methanol after interception is reduced by 10-80%. The invention can increase the methanol utilization rate of the whole methanol fuel cell system by 1-5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com