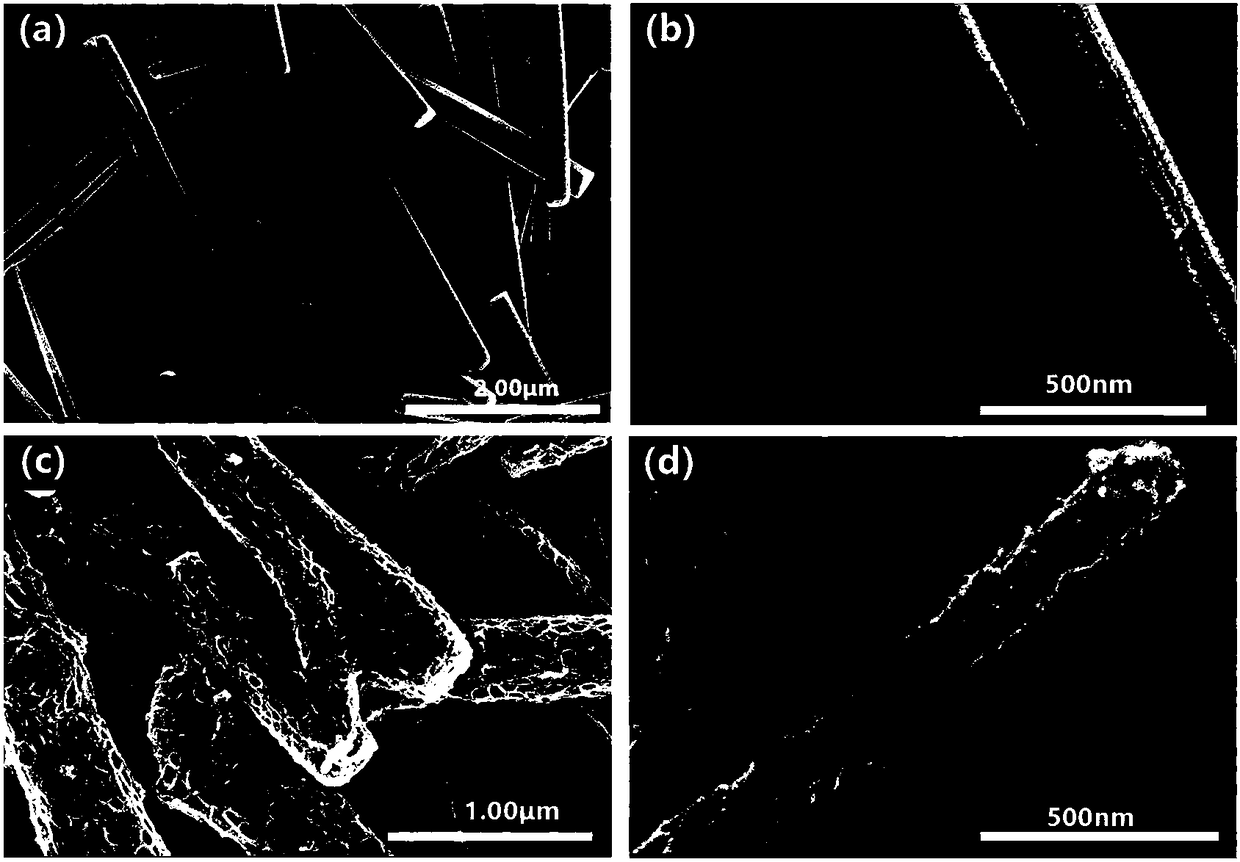

Multi-level N-doped carbon nano-rod composite material and preparation method thereof

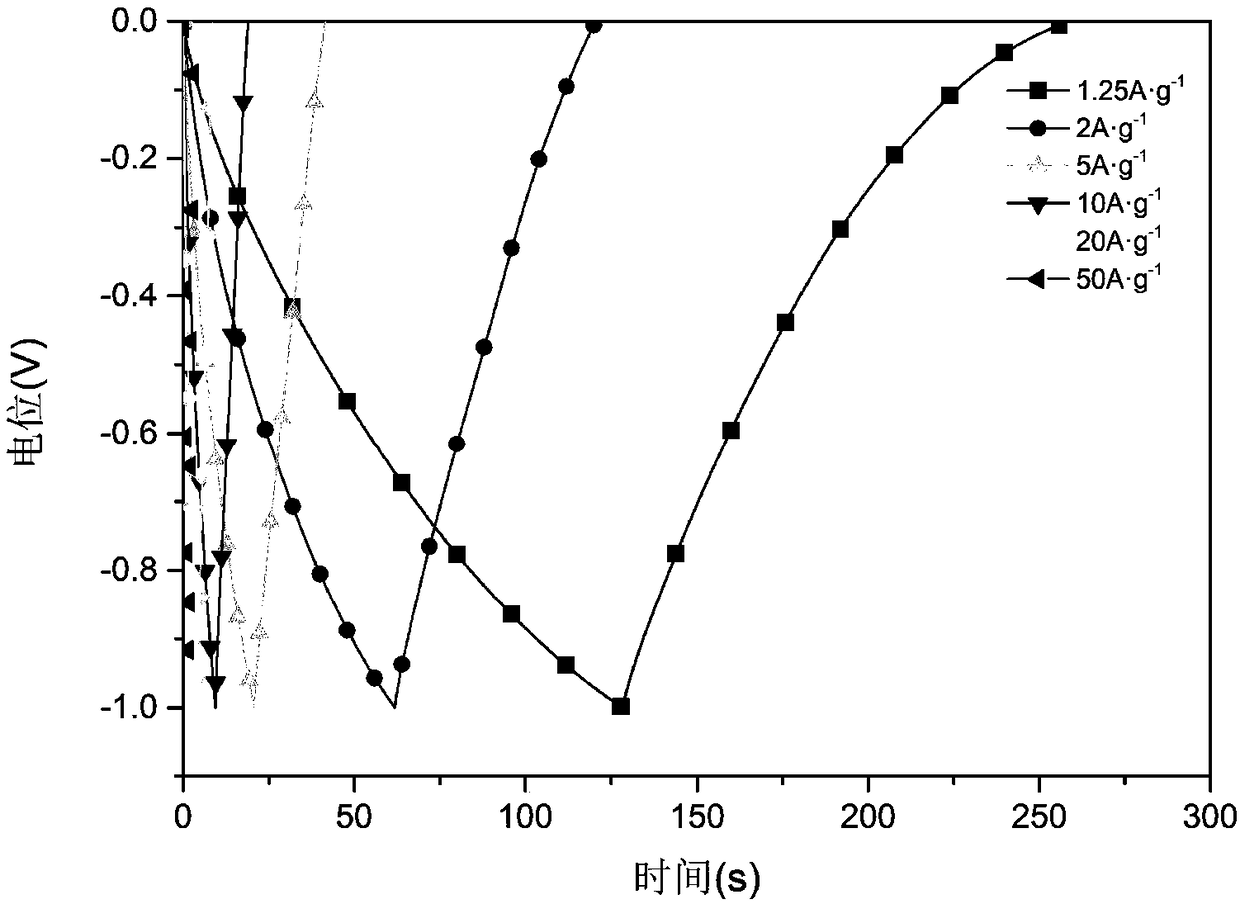

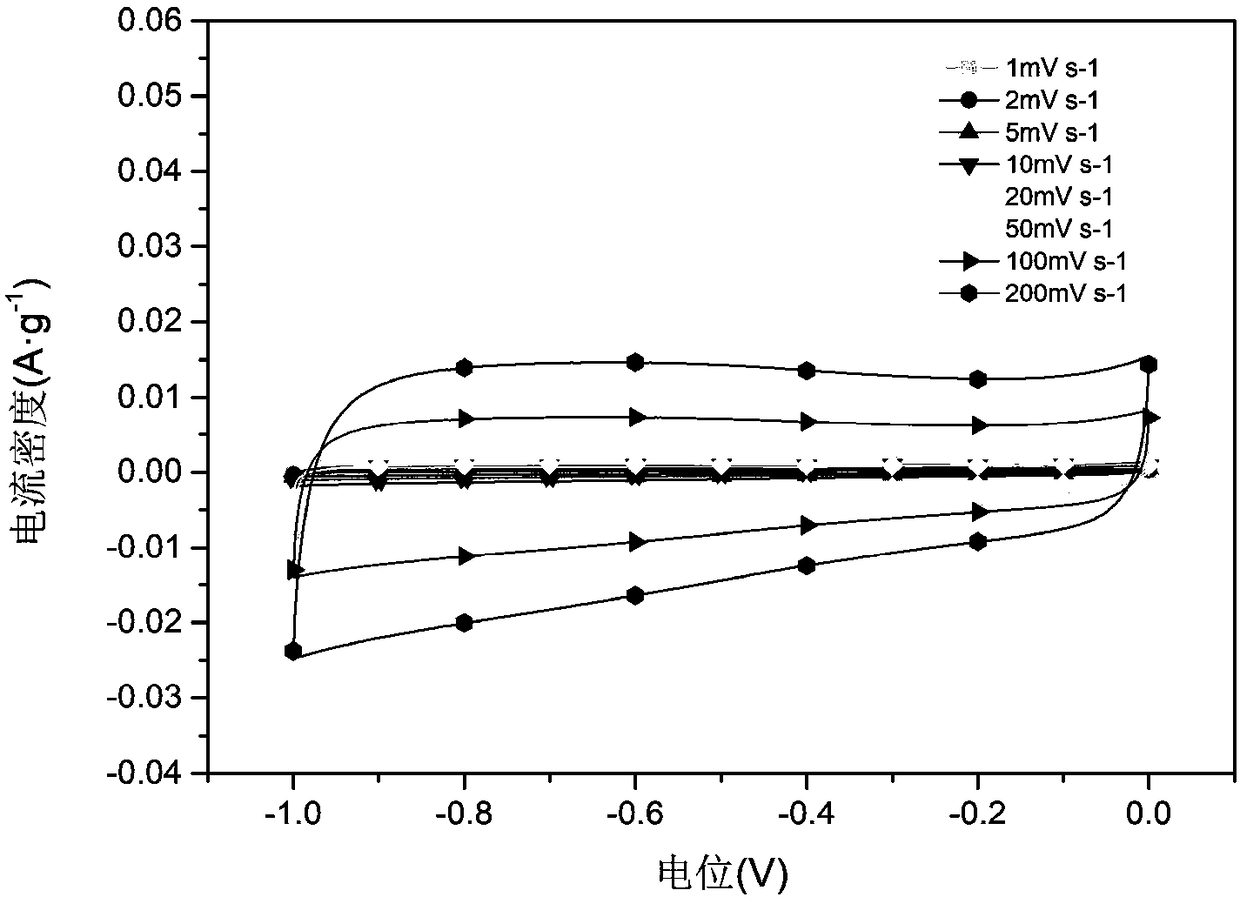

A technology of carbon nanorods and composite materials, applied in the field of material chemistry, can solve problems such as poor cycle performance, lower rate performance and power density, poor conductivity, etc., and achieve good capacitance performance, large specific surface area, and wide application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In this embodiment, the steps of the method for preparing the multi-level N-doped carbon nanorod composite material are as follows:

[0030] (1) Preparation of Zn(BTC) precursor:

[0031] (a) Add 0.4585g zinc acetate dihydrate to 4.22ml deionized water, stir until a colorless and transparent solution is formed, wherein [Zn 2+ ]=0.495mol / L;

[0032] (b) Dissolve 0.2625g of trimesic acid in 8.34ml of absolute ethanol, stir until a colorless and transparent solution is formed, wherein [BTC 3- ]=0.150mol / L;

[0033] (c) During the stirring process, add the solution of (b) dropwise to the solution obtained in (a), after ultrasonication for 10 minutes, transfer the reactant to a hydrothermal kettle, keep it at 175°C for 24 hours, and then cool to room temperature ;

[0034] (d) The product was collected by centrifugation, washed with absolute ethanol, and then dried at 200° C. for 2 h;

[0035] (2) Preparation of ZnO@C template: put the Zn(BTC) precursor into a tube furn...

Embodiment 2

[0043] In this embodiment, the steps of the method for preparing the multi-level N-doped carbon nanorod composite material are as follows:

[0044] (1) Preparation of Zn(BTC) precursor:

[0045] (a) Add 0.4585g zinc acetate dihydrate to 4.22ml deionized water, stir until a colorless and transparent solution is formed, wherein [Zn 2+ ]=0.495mol / L;

[0046] (b) Dissolve 0.525g of trimesic acid in 8.34ml of absolute ethanol, stir until a colorless and transparent solution is formed, wherein [BTC 2- ]=0.2996mol / L;

[0047] (c) During the stirring process, the solution of (b) was added dropwise to the solution obtained in (a), and after ultrasonication for 10min, the reactant

[0048] Move to a hydrothermal kettle, keep warm at 175°C for 24h, then cool to room temperature;

[0049] (d) The product was collected by centrifugation, washed with absolute ethanol, and then dried at 200° C. for 2 h;

[0050] (2) Preparation of ZnO@C template: put the Zn(BTC) precursor into a tube fu...

Embodiment 3

[0058] In this embodiment, the steps of the method for preparing the multi-level N-doped carbon nanorod composite material are as follows:

[0059] (1) Preparation of Zn(BTC) precursor:

[0060] (a) Add 0.4585g zinc acetate dihydrate to 4.22ml deionized water, stir until a colorless and transparent solution is formed, wherein [Zn 2+ ]=0.495mol / L;

[0061] (b) Dissolve 0.63g of trimesic acid in 8.34ml of absolute ethanol and stir until a colorless and transparent solution is formed, wherein [BTC 2- ]=0.359mol / L;

[0062] (c) During the stirring process, add the solution of (b) dropwise to the solution obtained in (a), after ultrasonication for 10 minutes, transfer the reactant to a hydrothermal kettle, keep it at 175°C for 24 hours, and then cool to room temperature ;

[0063] (d) The product was collected by centrifugation, washed with absolute ethanol, and then dried at 200° C. for 2 h;

[0064] (2) Preparation of ZnO@C template: put the Zn(BTC) precursor into a tube fur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com