Semiautomatic hollow column soil sample making device

A technology for making hollow cylinders and devices, which is applied in the direction of measuring devices, test sample preparation, sampling, etc., which can solve problems such as low efficiency and affecting the quality of soil sample production, achieve good results, save energy and time, and uniform rotation speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

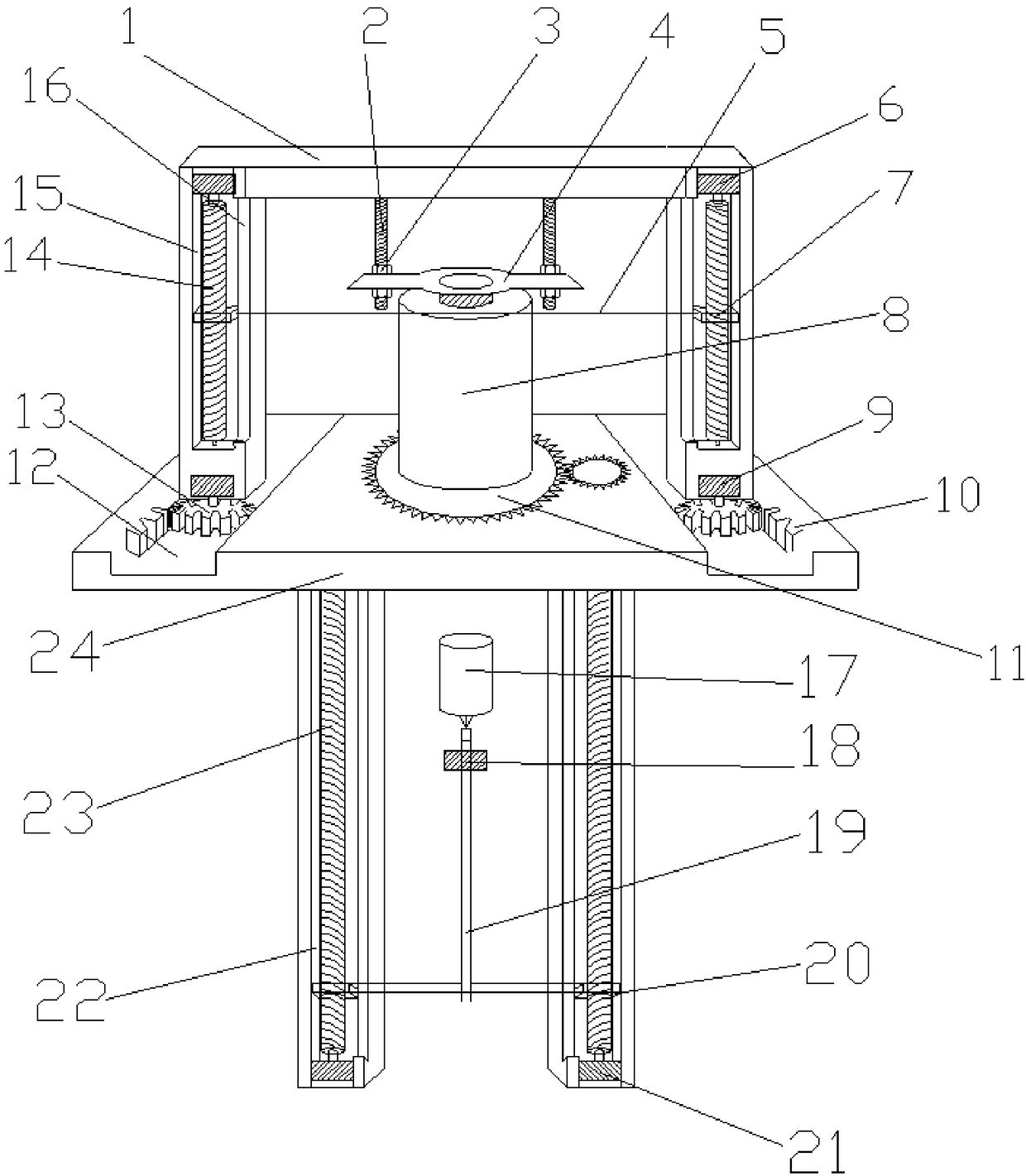

[0020] Such as figure 1 As shown, a semi-automatic hollow cylindrical soil sample production device includes a fixed cover plate 4, a soil cutting wire 5, a middle partition 24, a soil cutting wire knife holder, a tray 11, a first stepping motor 6, and a second stepping motor 9. The third stepper motor, PLC, the earth-taking cylinder 17, the first stepper motor 6, the second stepper motor 9, and the third stepper motor are connected to the PLC respectively;

[0021] There is a central through hole in the middle of the middle partition plate 24, and two parallel first chute 12s are arranged on both sides, and the side wall of the first chute 12 has a rack structure 10; The first bracket 16 installed directly and the beam 1 fixed on the top of the first bracket 16 are composed, and the fixed cover plate 4 is installed under the beam 1 through two bolts 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com