Interior wall scaffold for masonry and using method thereof

A technology for scaffolding and interior walls, which is applied to the accessories of scaffolding, buildings, building structures, etc. It can solve the problems of easy dryness and cracking of scaffolding eyes, cumbersome sealing of scaffolding eyes, and affecting construction speed. Low, speed up the effect of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

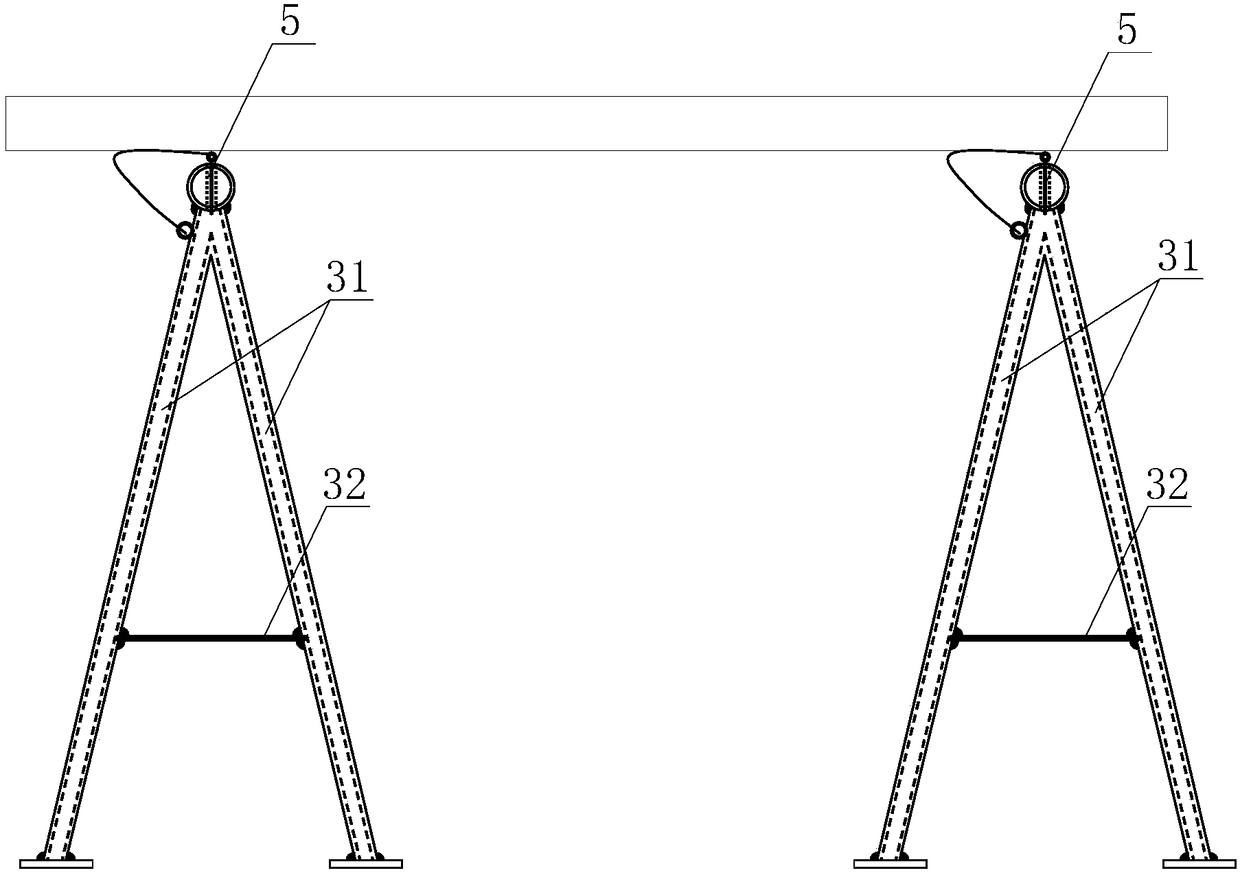

[0032] Example: such as figure 1 , figure 2 with image 3 As shown, a kind of interior wall scaffolding for masonry, including a support and a cross bar 1, one end of the cross bar 1 is fixedly connected to the support, and the other end is fixedly connected with an angle steel 2 for inserting into the vertical seam of the interior wall , The length ratio of the cross bar 1 to the angle steel 2 is 5-10:1.

[0033] further as figure 1 As shown, the length ratio of the cross bar 1 to the angle steel 2 is 20:3. Specifically, the length of the cross bar 1 is 1.2m, and the length of the angle steel 2 is 0.18m.

[0034] further as figure 1 As shown: the support member is a tripod 3 , and the crossbar 1 is vertically and fixedly connected to the tip of the tripod 3 . One end of the crossbar 1 is sleeved with a fixing part 4 , and the crossbar 1 is vertically connected to the tripod 3 through the fixing part 4 . The fixing part 4 includes a sleeve 41 and a support 42 connected...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com