Cast-in-place pile side post-grouting device and method

A technology of grouting device and cast-in-place pile, which is applied in the direction of sheet pile wall, building, foundation structure engineering, etc., can solve the problems of not well controlling the effective pressure of mud, potential safety hazards, influence of pile body strength, etc., and avoid corrosion of steel bars hidden effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

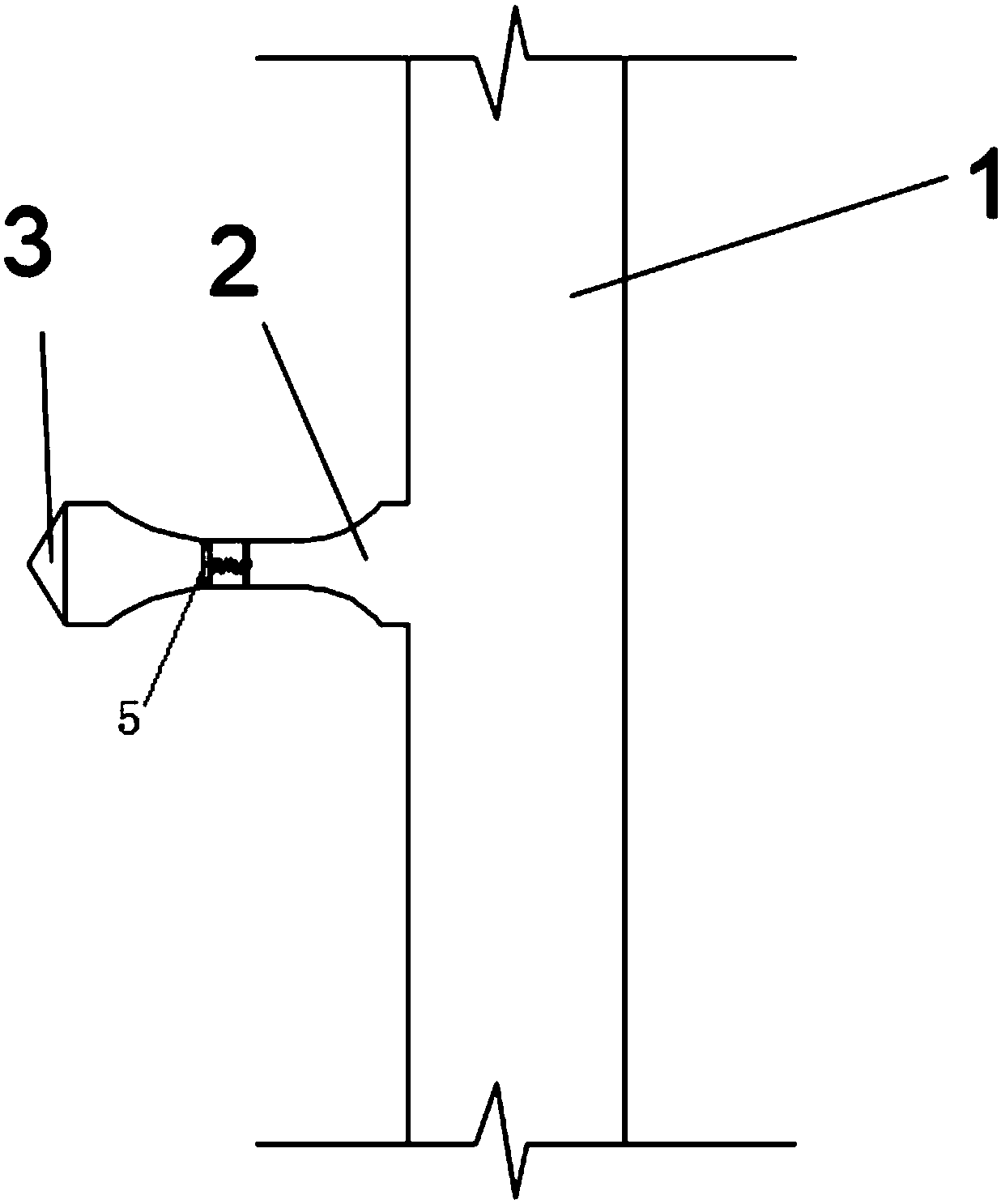

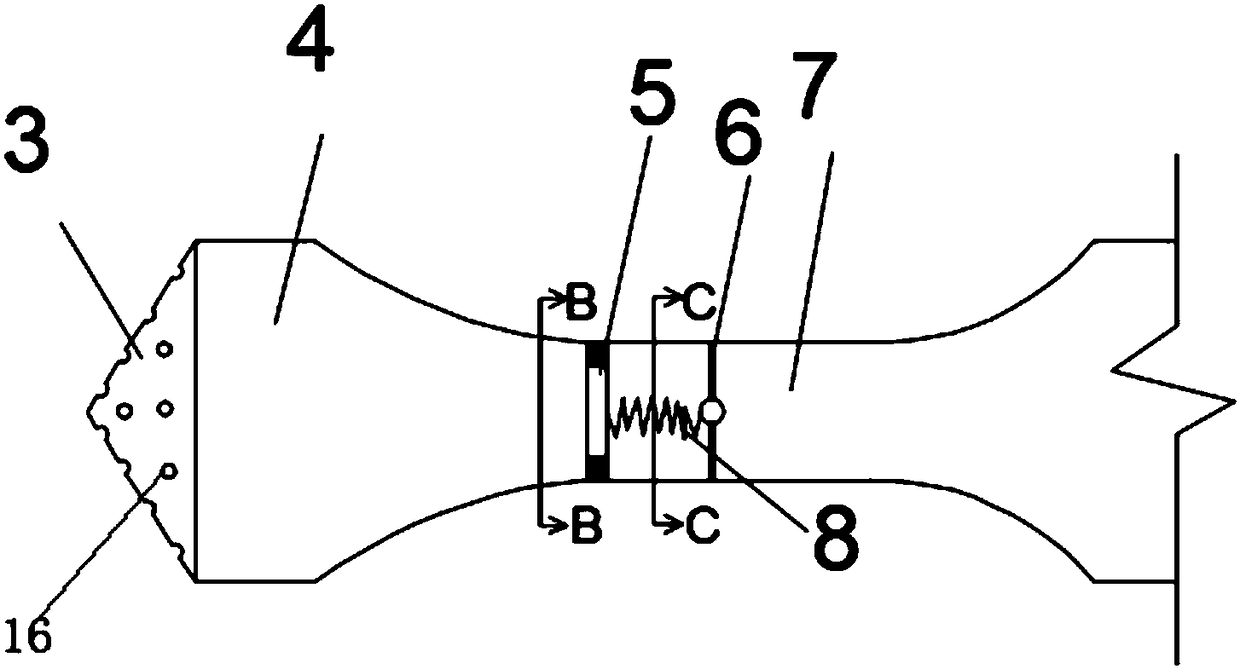

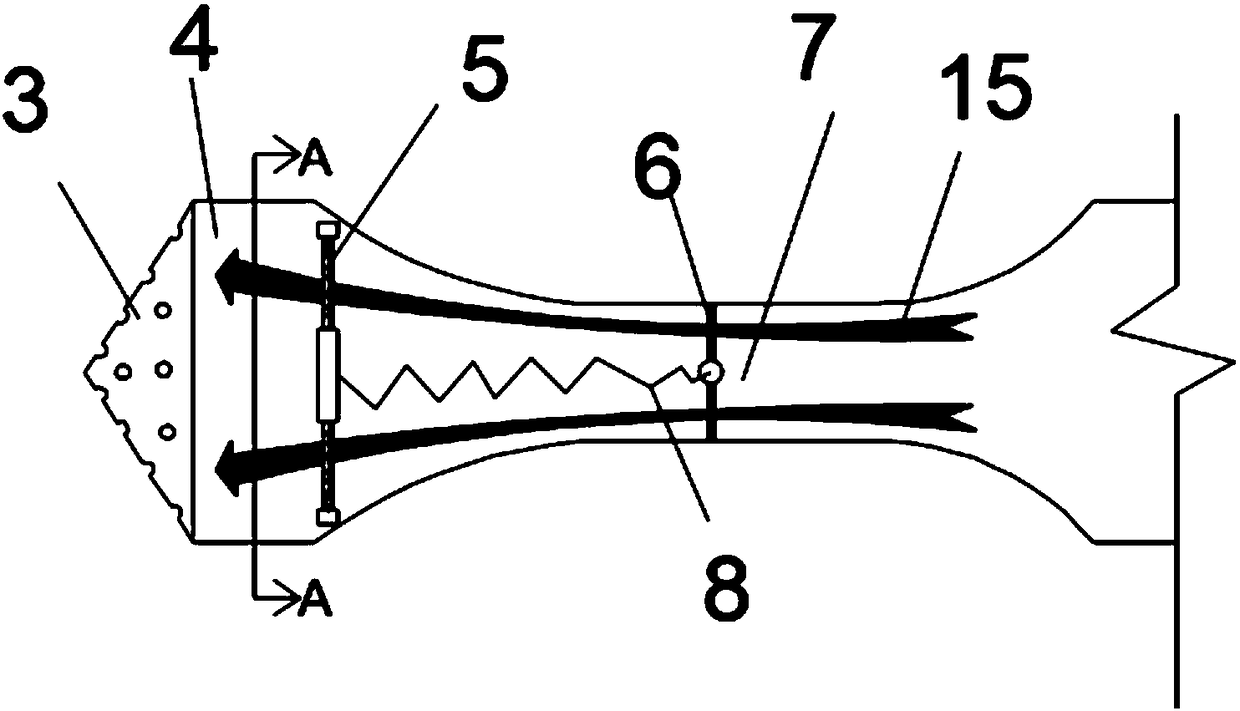

[0045] like figure 1 As shown, a post-grouting device for cast-in-place piles includes a longitudinal grouting main pipe 1, a horizontal grouting branch pipe 2, a grouting head 3 and a one-way check pressure valve 5, and the vertical grouting main pipe 1 The bottom end is closed, and there is an opening on the side of the longitudinal grouting main pipe 1, one end of the horizontal grouting branch pipe 2 is connected to the opening on the longitudinal grouting main pipe 1, and the grouting head 3 is installed on the horizontal grouting branch pipe 2 The other end of the horizontal grouting branch pipe 2 is divided into a middle small section section 7 and a large section section 4 at both ends, and the middle small section section 7 is respectively connected with the large section section 4 at both ends through a smooth necking section, The one-way check pressure valve 5 is installed at the middle small-section section 7 of the horizontal grouting branch pipe 2. When the one-w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com