Structural design and construction method of a composite face sand and gravel dam

A technology of sand and gravel dams and composite panels, which is applied in the direction of dams, barrages, barrages, etc., can solve the problems of inability to accurately predict the service life of the dam type, insufficient system depth, and less quantitative analysis, so as to reduce the amount of filling work , reduce investment, and prevent penetration damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described below in conjunction with accompanying drawing and specific embodiment:

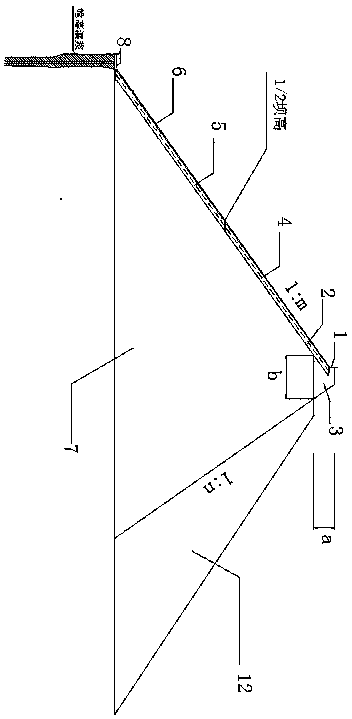

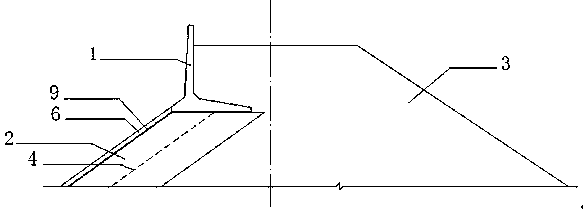

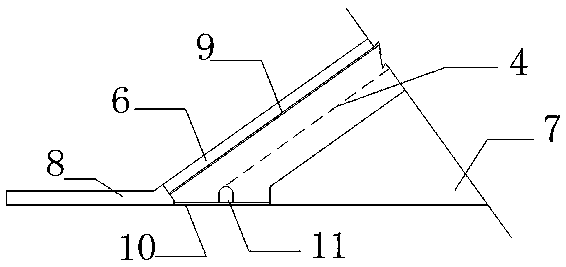

[0027] figure 1 It is a schematic diagram of the dam body structure of the composite face sand and gravel dam designed by the present invention. A structural design method for a composite face sand and gravel dam, comprising a sand and gravel dam body composed of a main rockfill area 7 and a downstream rockfill area 12 located on the downstream slope of the main rockfill area 7, wherein the main rockfill area 7 is filled with river bed sand and gravel; the downstream rockfill area 12 is filled with sand and gravel and excavated gravel. The height of the downstream rockfill area 12 is lower than that of the main rockfill area 7 a m, the upstream slope of the gravel dam body is provided with a cushion layer and a face layer 6 parallel to the cushion layer, the top of the gravel dam body is provided with a wave wall 1; the bottom of the face layer 6 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com