Anti-aging agent for promoting grain filling special for corn and application method thereof

A technology dedicated to corn and application methods, applied in the direction of fertilization methods, applications, fertilization devices, etc., can solve the problems of large impact, unstable increase in production and efficiency, etc., to prevent premature senescence of leaves, prolong physiological function period, improve yield and economical benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

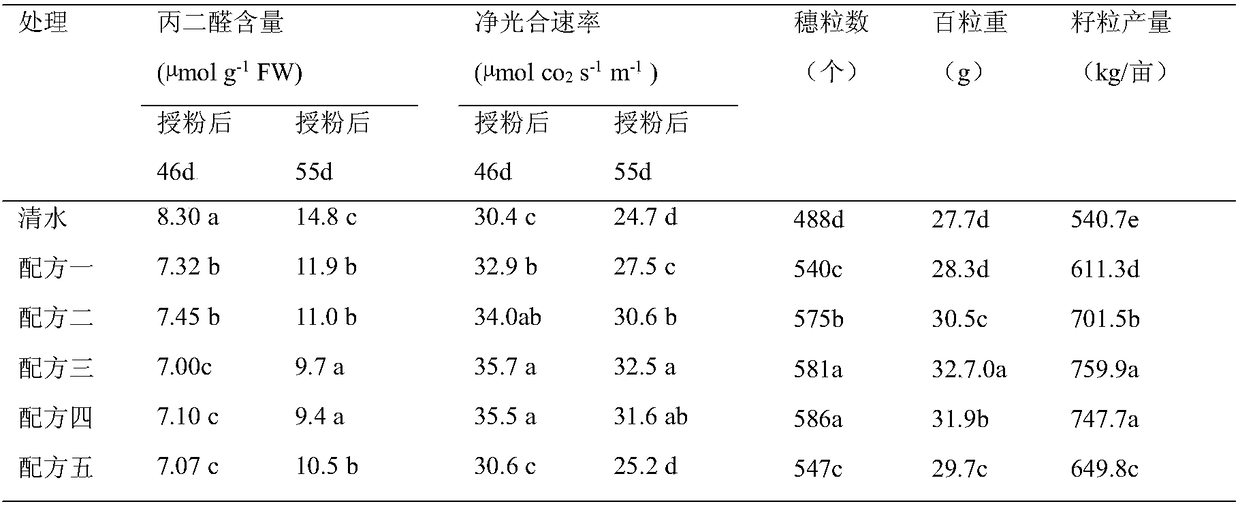

[0017] Embodiment 1 field bioassay test

[0018] The test site is Nanjing City, Jiangsu Province, with Suyu 29 as the test material, sown on April 25, with a density of 60,000 plants·hm -2 . Set two treatments of spraying anti-aging agent and clear water, anti-aging agent is 5 formulas respectively, each formula has 4 repetitions, and each plot is 30m 2 .

[0019] Formula one, the thiadidiazuron of 0.003mg / L, the calcium nitrate (Ca(NO) of 350mg / L 3 ) 2 ), 80mg / L magnesium sulfate (MgSO 4 ), 150mg / L of urea (CO(NH 2 ) 2 ), the surfactant (Tween 20) of 5ml / L.

[0020] Formula two, the thiadizuron of 0.003mg / L, the calcium nitrate (Ca(NO) of 350mg / L 3 ) 2 ), 100mg / L of magnesium sulfate (MgSO 4 ), 200mg / L of urea (CO(NH 2 ) 2 ), the surfactant (Tween 20) of 5ml / L.

[0021] Formula three, 0.005mg / L of thiadizuron, 350mg / L of calcium nitrate (Ca(NO 3 ) 2 ), 120mg / L magnesium sulfate (MgSO 4 ), 250mg / L of urea (CO(NH 2 ) 2 ), the surfactant (Tween 20) of 5ml / L.

...

Embodiment 2

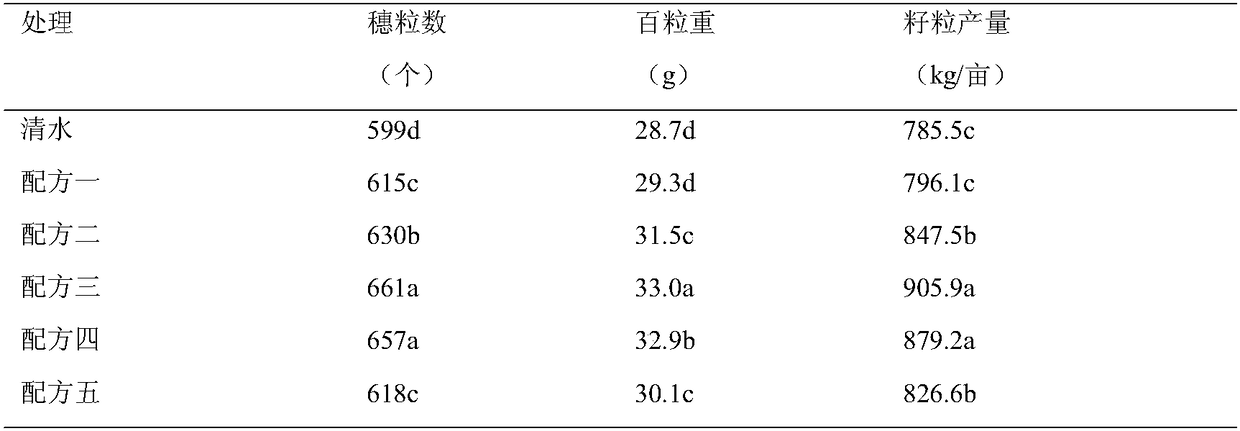

[0030] Embodiment 2 Field yield test

[0031] The test site is Gongzhuling City, Jilin Province. Taking Xianyu 335 as the test material, it was sown on April 15, with a density of 67500 plants·hm -2 . Set two treatments of spraying anti-aging agent and clear water, anti-aging agent is 5 formulas respectively, each formula has 3 repetitions, and each plot is 60m 2 .

[0032] Formula one, the thiadidiazuron of 0.003mg / L, the calcium nitrate (Ca(NO) of 350mg / L 3 ) 2 ), 80mg / L magnesium sulfate (MgSO 4 ), 150mg / L of urea (CO(NH 2 ) 2 ), the surfactant (Tween 20) of 5ml / L.

[0033] Formula two, the thiadizuron of 0.003mg / L, the calcium nitrate (Ca(NO) of 350mg / L 3 ) 2 ), 100mg / L of magnesium sulfate (MgSO 4 ), 200mg / L of urea (CO(NH 2 ) 2 ), the surfactant (Tween 20) of 5ml / L.

[0034] Formula three, 0.005mg / L of thiadizuron, 350mg / L of calcium nitrate (Ca(NO 3 ) 2 ), 120mg / L magnesium sulfate (MgSO 4 ), 250mg / L of urea (CO(NH 2 ) 2 ), the surfactant (Tween 20) of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com