A kind of preparation method of anti-scratch hydrophobic anti-reflection film

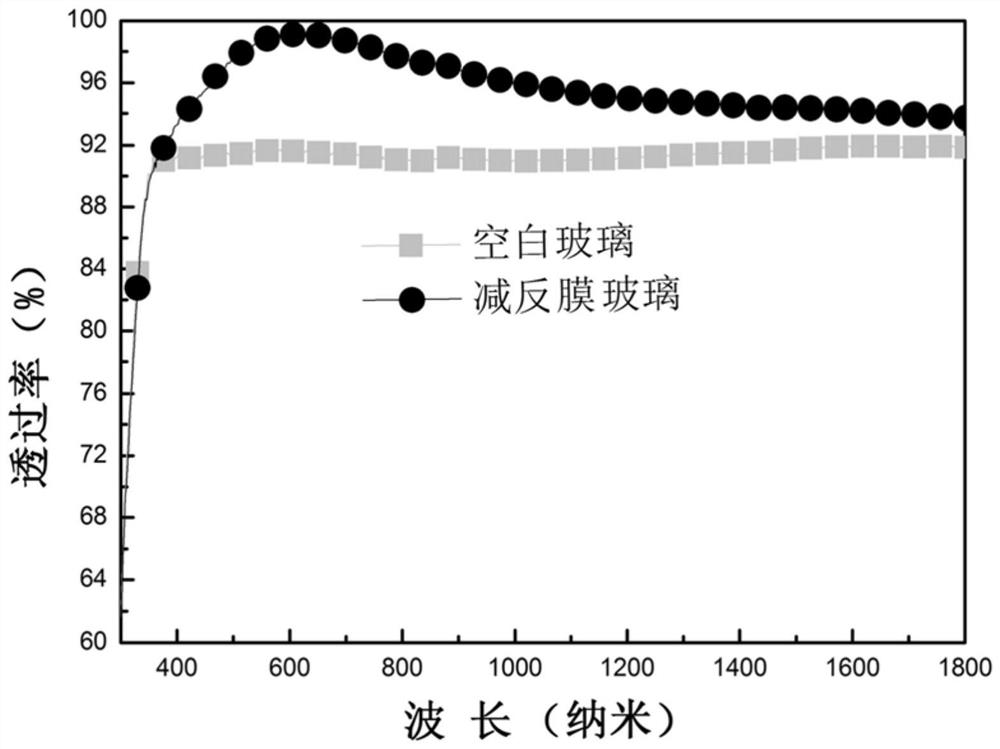

An anti-reflection coating and hydrophobic technology, applied in the coating and other directions, can solve the problems of poor wear resistance of nano-particle anti-reflection coatings, unfavorable surface adhesion of anti-reflection coatings and glass substrates, and discontinuous microscopic morphology of thin films.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

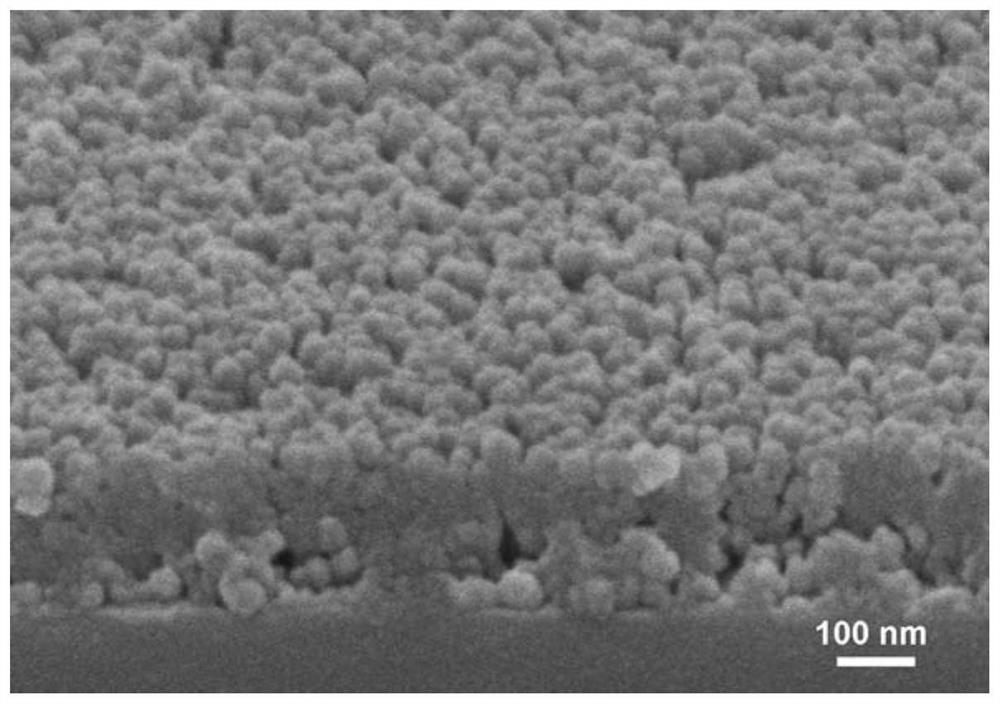

[0034] The preparation method of the scratch-resistant hydrophobic anti-reflection film of embodiment 1 comprises the following steps:

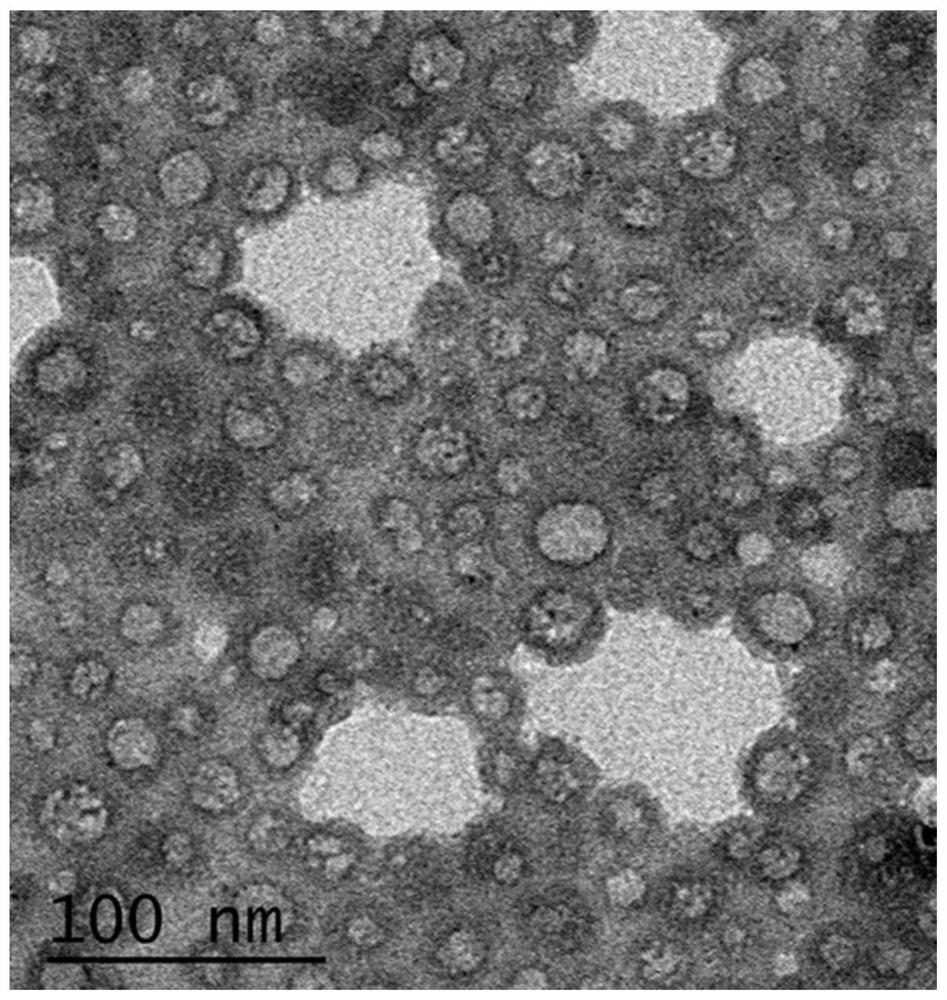

[0035] (1) Using tetraethyl orthosilicate as the precursor silicon source I to prepare hollow spheres of SiO 2 Nanoparticle solution, obtain solution I, the preparation process of this solution I is:

[0036]① Add ammonia monohydrate to water to obtain an aqueous solution of ammonia monohydrate, then disperse polyacrylic acid into the aqueous solution of ammonia monohydrate to obtain a mixed solution I-1;

[0037] ②Add mixed solution I-1 and precursor silicon source I to ethanol in sequence to obtain mixed solution I-2;

[0038] ③ Stir the mixed solution I-2, and reflux for 24 hours after aging for 18 hours to remove the ammonia water in the solution to obtain the solution I;

[0039] The molar ratio of ammonia monohydrate, water, polyacrylic acid, precursor silicon source I, and ethanol used successively in the preparation process of the a...

Embodiment 2

[0046] The preparation method of the scratch-resistant hydrophobic anti-reflection film of embodiment 2 comprises the following steps:

[0047] (1) Using tetraethyl orthosilicate as the precursor silicon source I to prepare hollow spheres of SiO 2 Nanoparticle solution, obtain solution I, the preparation process of this solution I is:

[0048] ① Add ammonia monohydrate to water to obtain an aqueous solution of ammonia monohydrate, then disperse polyacrylic acid into the aqueous solution of ammonia monohydrate to obtain a mixed solution I-1;

[0049] ②Add mixed solution I-1 and precursor silicon source I to ethanol in sequence to obtain mixed solution I-2;

[0050] ③ Stir the mixed solution I-2, reflux for 48 hours after aging for 12 hours, remove the ammonia water in the solution, and obtain the solution I;

[0051] The molar ratio of ammonia monohydrate, water, polyacrylic acid, precursor silicon source I, and ethanol used successively in the preparation process of the abov...

Embodiment 3

[0058] The preparation method of the scratch-resistant hydrophobic anti-reflection film of embodiment 3 comprises the following steps:

[0059] (1) Using tetraethyl orthosilicate as the precursor silicon source I to prepare hollow spheres of SiO 2 Nanoparticle solution, obtain solution I, the preparation process of this solution I is:

[0060] ① Add ammonia monohydrate to water to obtain an aqueous solution of ammonia monohydrate, then disperse polyacrylic acid into the aqueous solution of ammonia monohydrate to obtain a mixed solution I-1;

[0061] ②Add mixed solution I-1 and precursor silicon source I to ethanol in sequence to obtain mixed solution I-2;

[0062] ③ Stir the mixed solution I-2, reflux for 36 hours after aging for 24 hours, remove the ammonia water in the solution, and obtain the solution I;

[0063] The molar ratio of ammonia monohydrate, water, polyacrylic acid, precursor silicon source I, and ethanol used successively in the preparation process of the abov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com