Technology for preparing purified water by well process reverse osmosis

A technology of reverse osmosis and pure water, applied in the direction of osmosis/dialysis water/sewage treatment, water/sewage treatment, non-polluted water treatment, etc., can solve the problems of difficult absorption of minerals, large total power consumption, and large power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

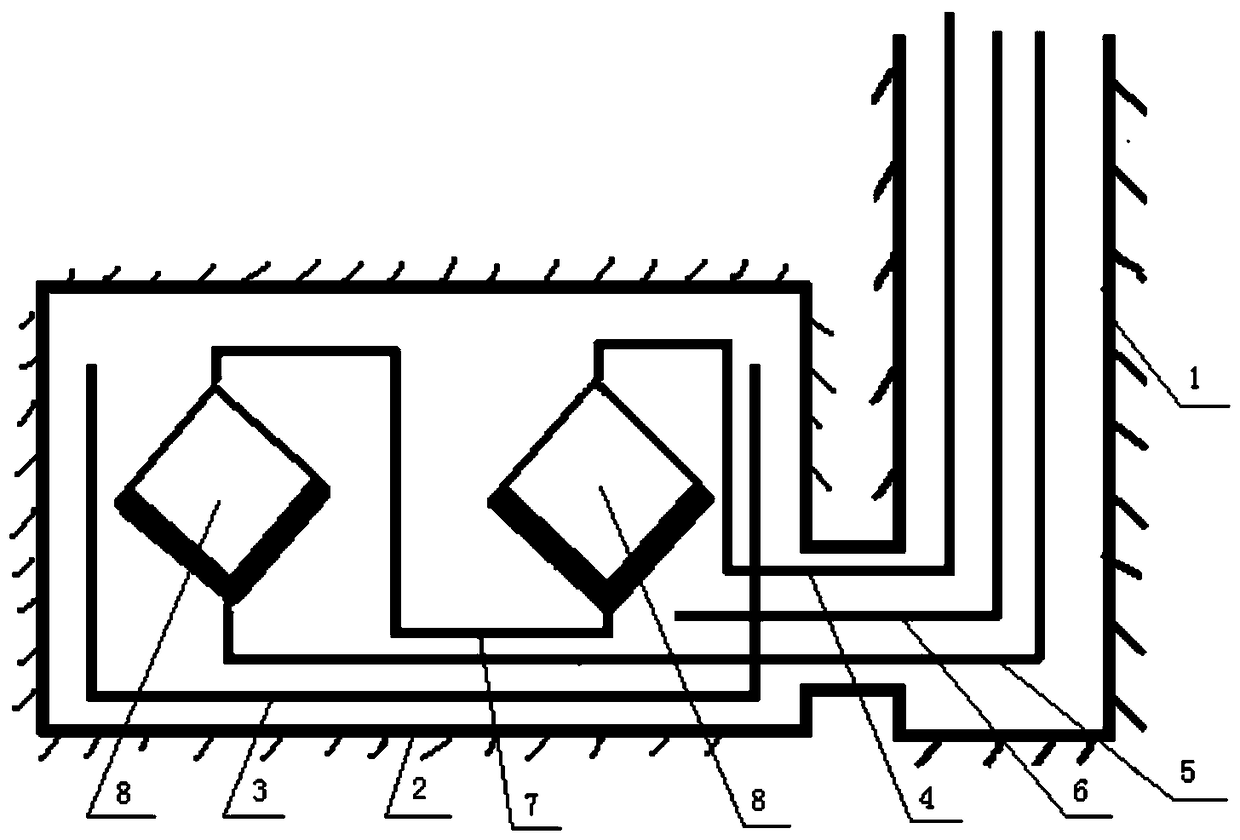

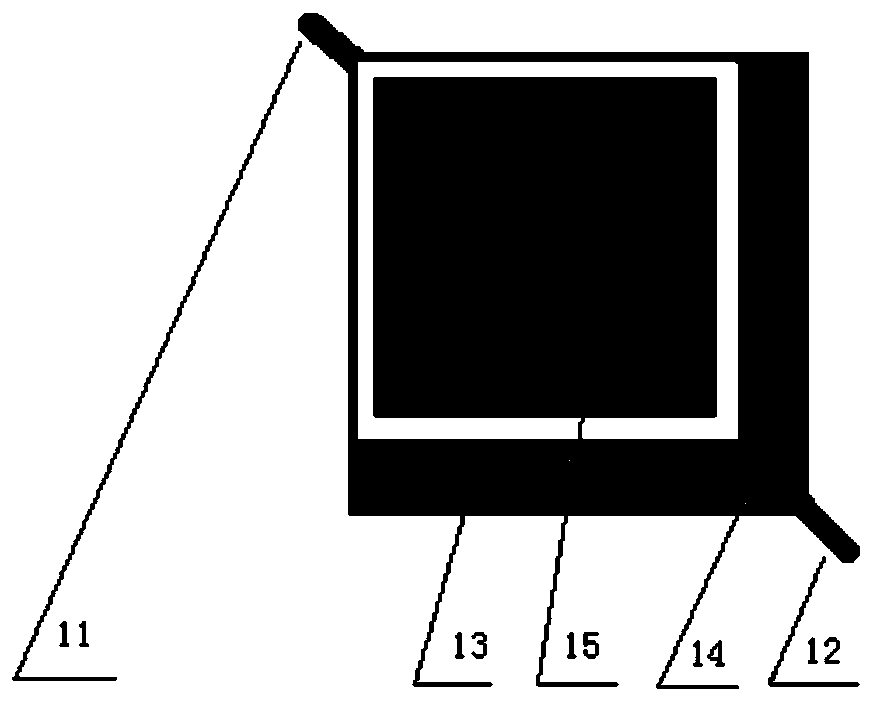

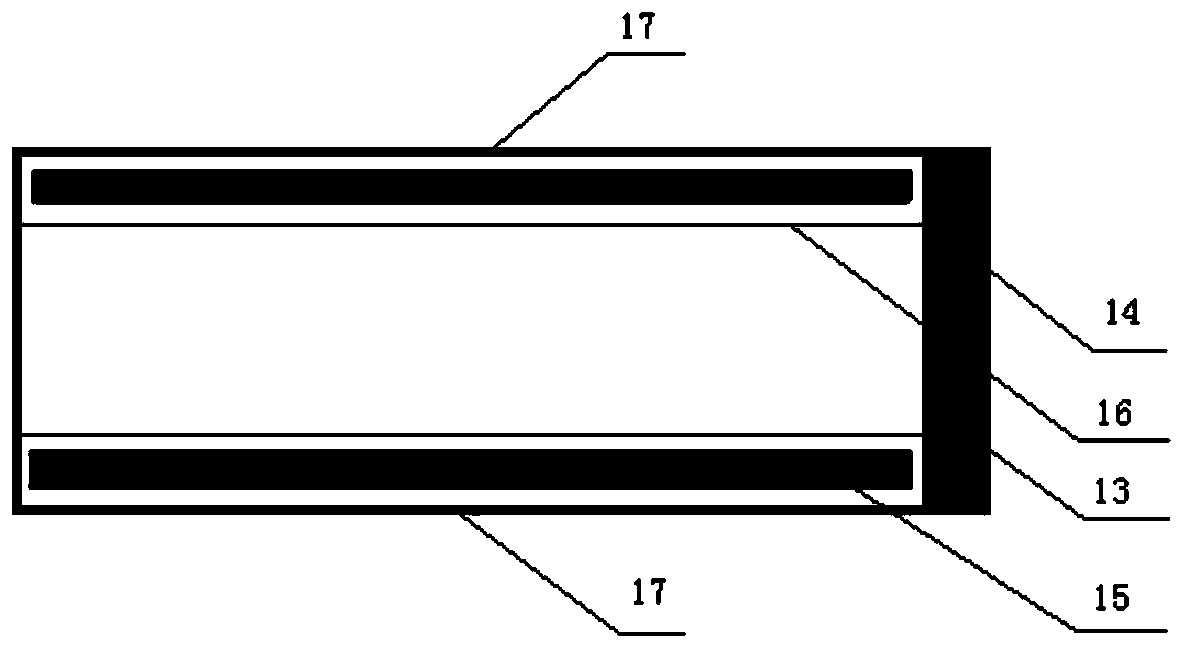

[0018] Such as figure 1 As shown, a technology for preparing pure water by well method reverse osmosis, the technology consists of vertical well 1, reverse osmosis chamber 2, reverse osmosis water tank 3, water inlet pipe 4, water outlet pipe 5, pure water pipe 6, connecting pipe 7, reverse osmosis The osmosis component consists of 8 components.

[0019] First, a vertical shaft 1 of a certain depth is dug from the surface to the ground, and its depth is determined by the user according to the required working pressure. About every 10 meters in depth increases the pressure by one atmosphere. Then open up a certain space as the reverse osmosis chamber 2 at the bottom of the shaft 1 to the side. The water inlet pipe 4 , the water outlet pipe 5 and the pure water pipe 6 are laid from the ground into the reverse osmosis chamber 2 via the shaft 1 . The reverse osmosis water tank 3 is placed in the reverse osmosis chamber 2 , and the reverse osmosis component 8 is placed in the rev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com