Driving control system used for servo motor

A servo motor, drive control technology, applied in the control system, AC motor control, electrical components, etc., can solve the problem that the servo motor cannot be accurately controlled, and achieve the effect of eliminating the influence and improving the control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the explanatory text.

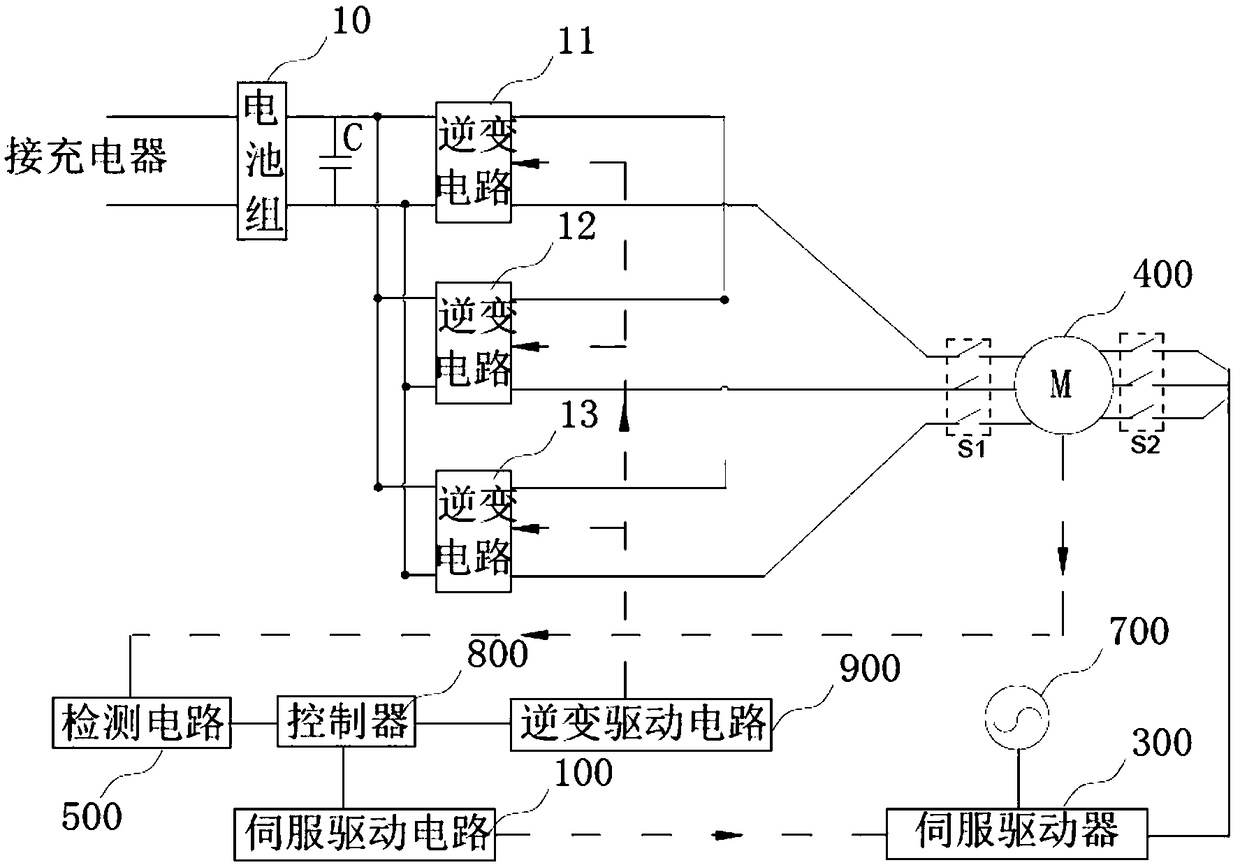

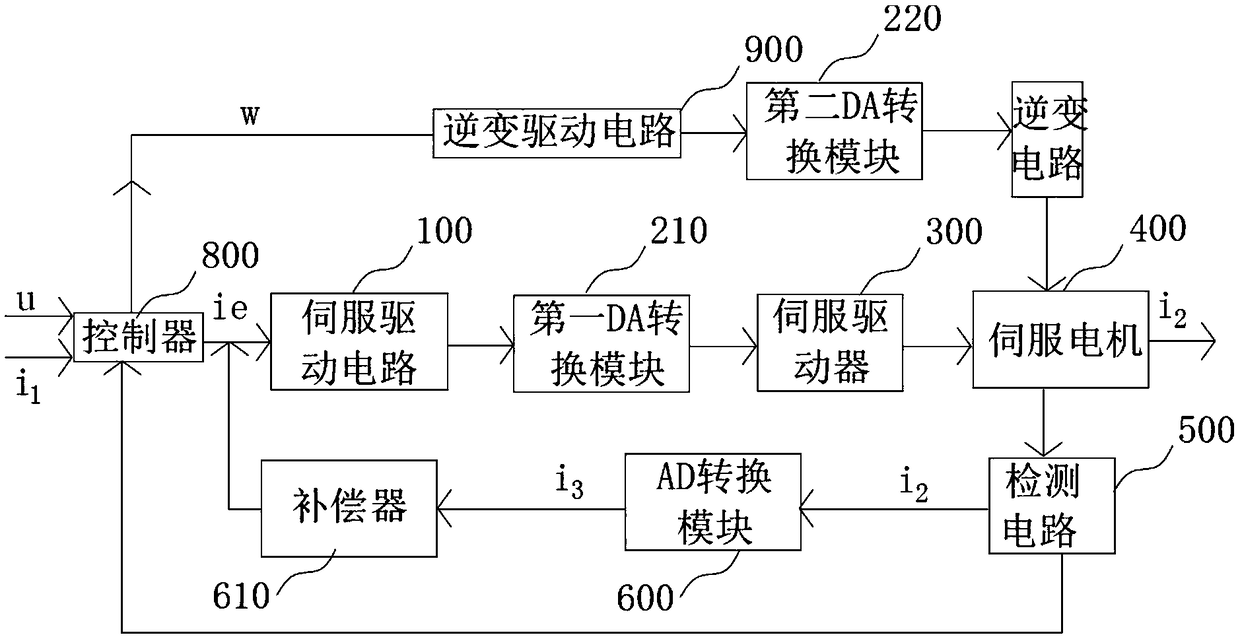

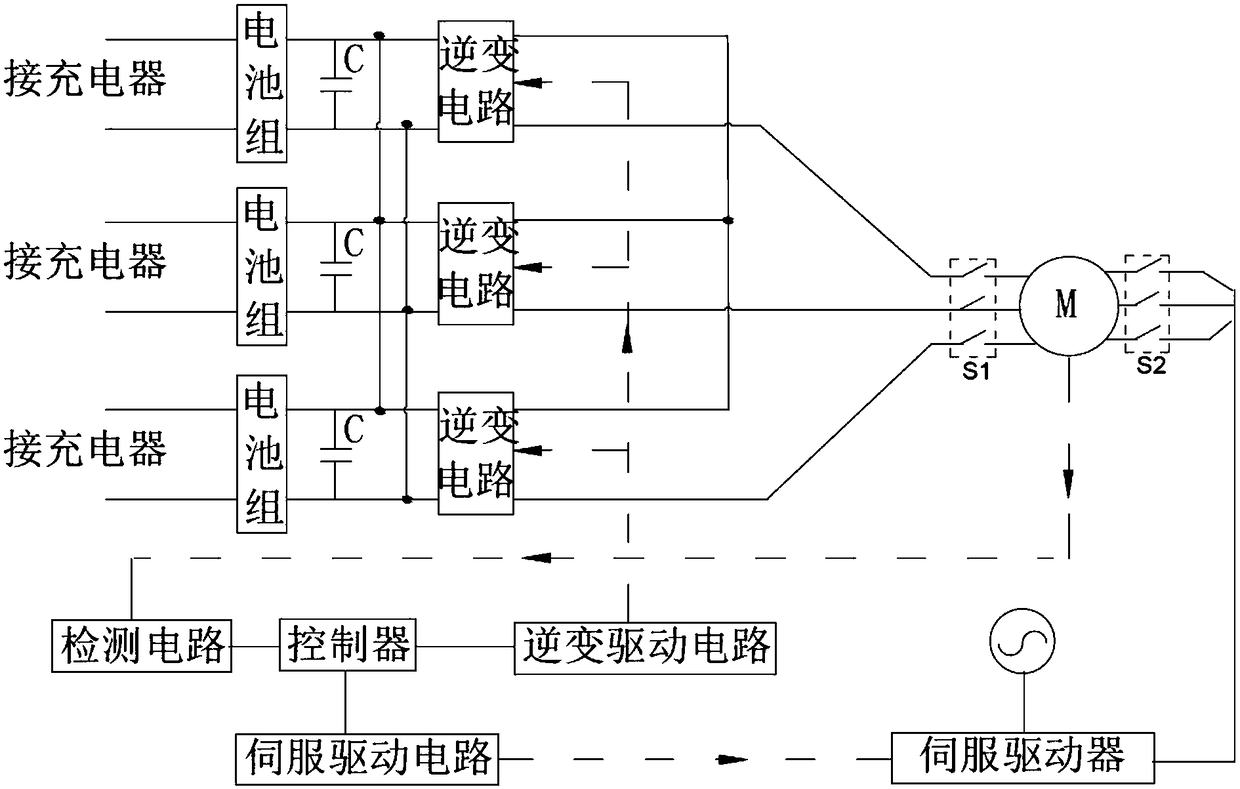

[0030] Such as Figure 1-2 As shown, the present invention provides a drive control system for a servo motor, wherein:

[0031] The input end of the servo drive circuit 100 is connected to the output end of the controller 800 of the servo motor 400. The controller 800 collects the output electrical signal of the servo motor 400 through a detection circuit 500 and feeds it back to the controller 800. Specifically Collect the voltage, current and phase of each phase of the servo motor stator.

[0032] The output end of the servo drive circuit 100 is connected to the signal input end of a servo driver 300, the power input end of the servo driver 300 is connected to a three-phase AC power supply 700, and the power output end of the servo drive circuit 100 is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com