Automatic power supply device installed beside hot metal ladle car

A technology of molten iron tank car and automatic power supply, which is applied in the substation/distribution device shell, circuit, current collector, etc., which can solve the problems of long construction period, complex structure, high cost, etc., and achieve prolonging service life, less investment and reasonable design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

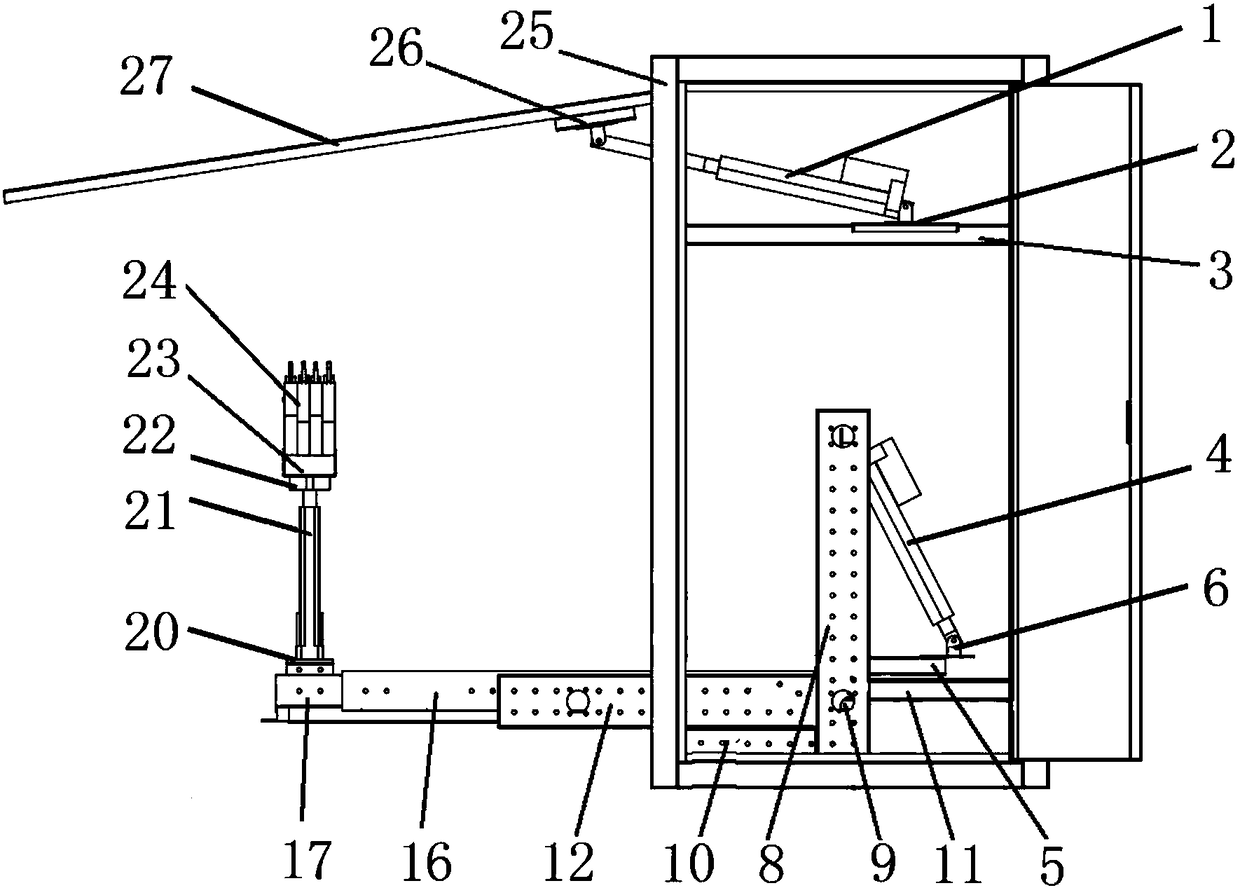

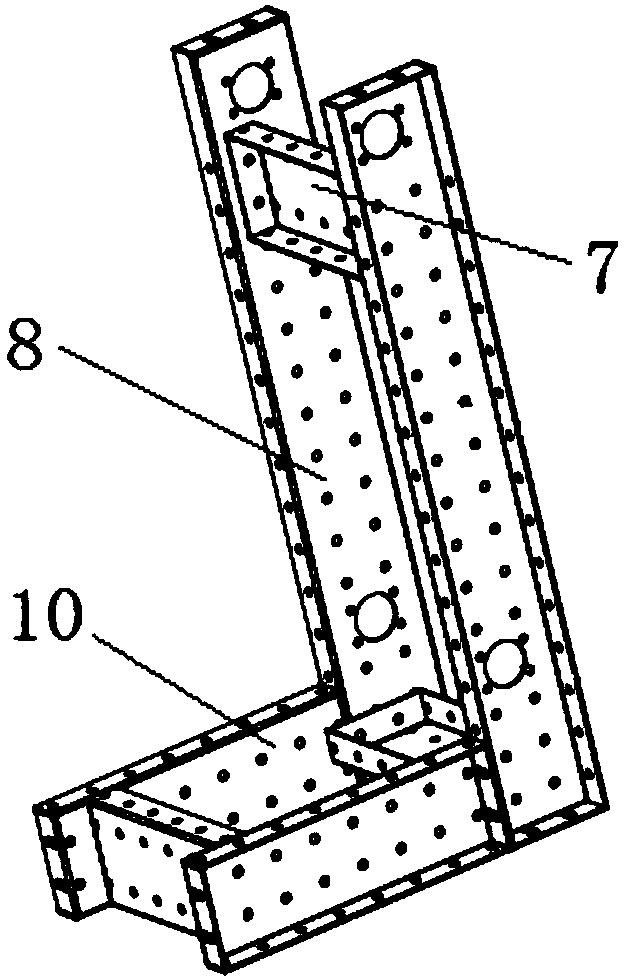

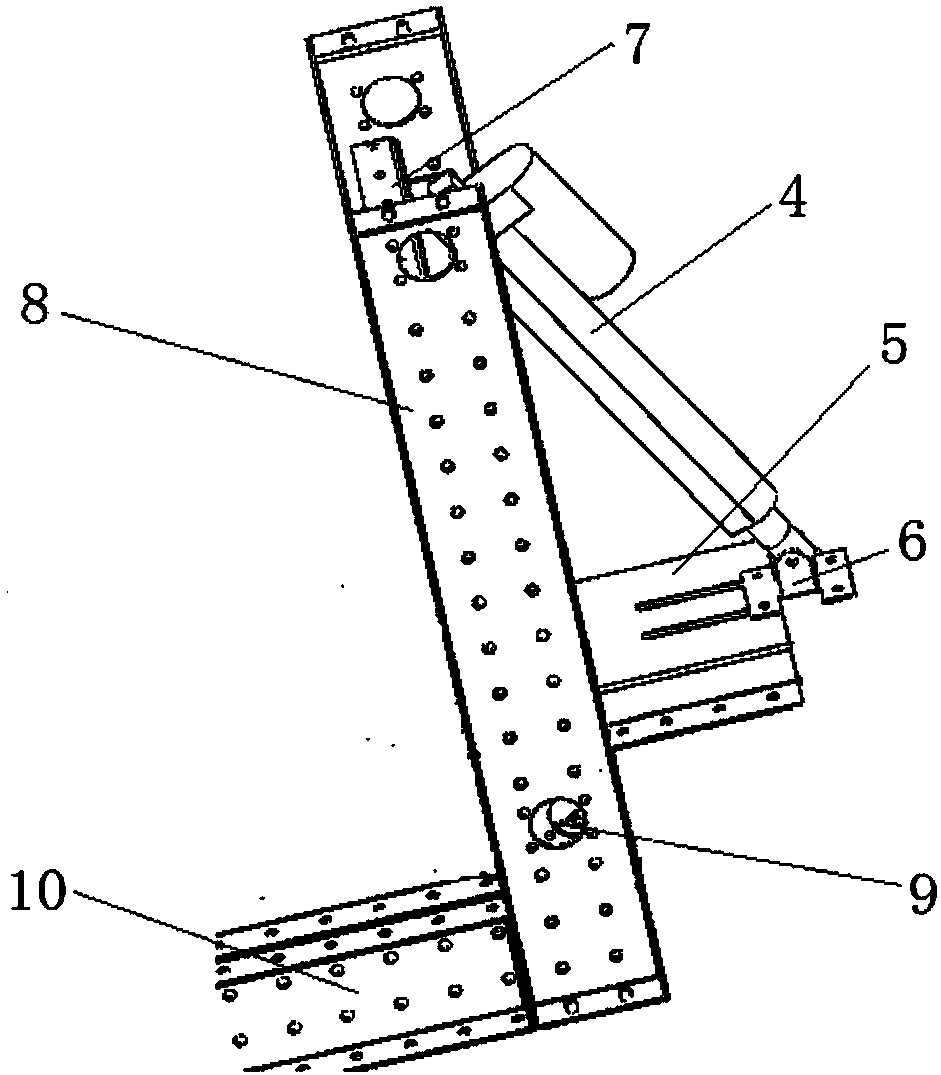

[0035] Embodiment 1: a kind of automatic power supply device installed on the side of the molten iron tank car provided by the present invention, its structure is as follows figure 1 shown. A power supply cabinet 25 is provided, and the cabinet is provided with a door switch mechanism, a pressing and lifting mechanism, a forward and backward mechanism, a lifting mechanism, and a collector contact mechanism. The actions of each mechanism are completed by their respective electric push rods. The electric push rods are all driven by 24V safe voltage, the power is 30W, and the wiring is 2-core wires. To realize all actions, only one 8-core cable needs to be drawn out to realize remote automatic control and power supply, so as to realize power supply for the molten iron tanker.

[0036] see figure 1 , 6 , the length, width and height of the power supply cabinet 25 in this embodiment are 600×400×1100mm, and the power supply cabinet is installed next to the parking space of the mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com