Fuel cell membrane electrode employing ruthenium telluride as cathode and preparation method

A fuel cell film and telluride technology, which is applied in fuel cells, battery electrodes, nanotechnology for materials and surface science, etc., can solve the problem of easily forming oxygen or the adsorption of various oxygen-containing ions, reducing battery performance, Platinum is easy to be oxidized and other problems, to achieve the effect of improving cathode poisoning resistance, improving methanol oxidation resistance, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

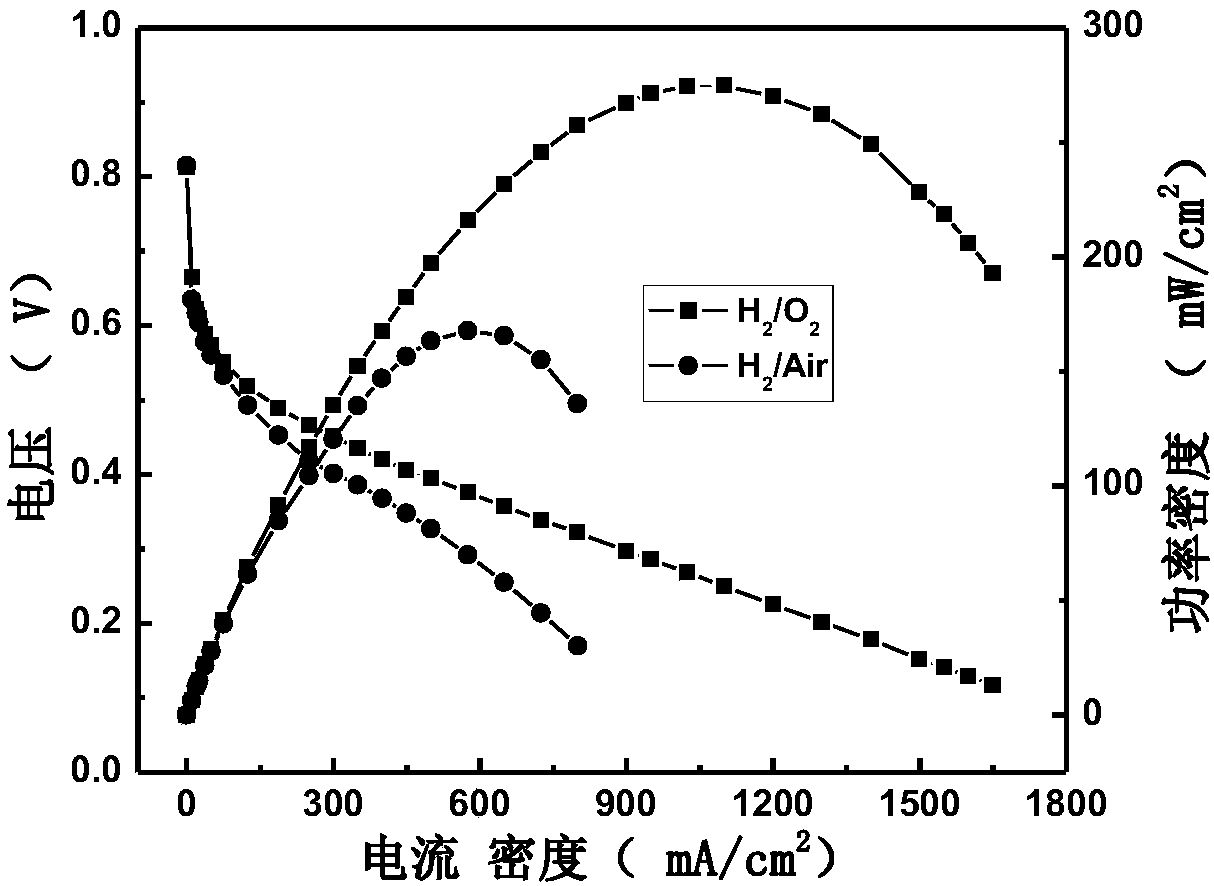

Embodiment 1

[0028] (1) The platinum mass fraction is 20%, and the carbon-supported platinum catalyst of Vulcan-XC72 is added to the mixed solution of deionized water and ethanol (volume ratio is 10:90), and then a certain amount of 5% mass fraction of Nafion is added. The solution was magnetically stirred for 1 hour, ultrasonically dispersed for 1 hour, and prepared into a slurry, so that the mass ratio of carbon-supported platinum and Nafion in the suspension was 60:40.

[0029] (2) Spray the slurry obtained in (1) evenly on one side of the Nafion-212 membrane with an ultrasonic sprayer to form an anode catalytic layer, and dry it in a vacuum oven. The spraying time was 30 minutes, the temperature was 85° C., and the platinum loading was 0.15 mg / cm2.

[0030] (3) Add a carbon-supported ruthenium-based telluride (RuTe2 / C, the carrier is Vulcan-XC72) catalyst into a mixed solution of deionized water and ethanol (volume ratio of 10:90) and then add a certain amount of 5% mass fraction of T...

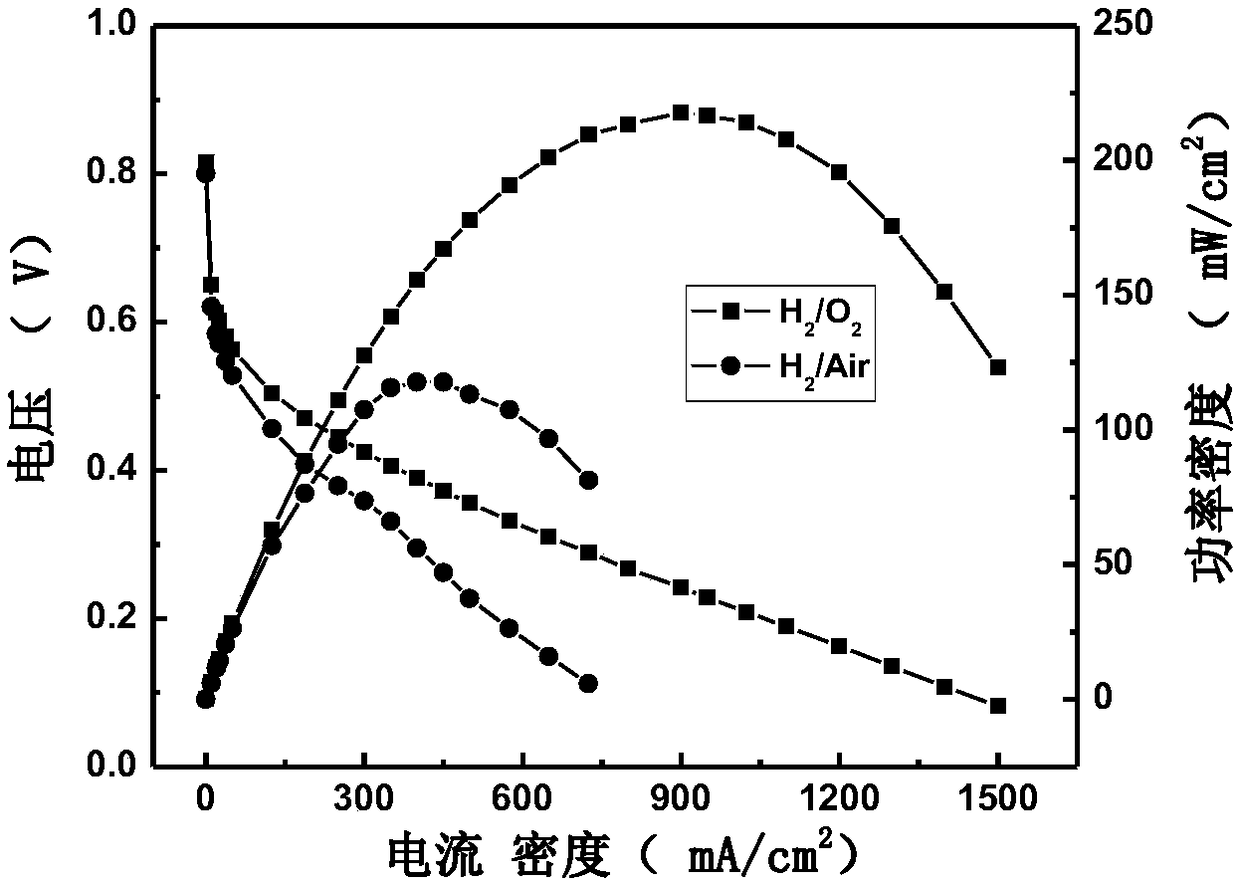

Embodiment 2

[0034] (1) Add a platinum mass fraction of 40% and a Vulcan-XC72R carbon-supported platinum catalyst into a mixture of deionized water and ethanol (volume ratio of 20:80) and then add a certain amount of 5% mass fraction of Nafion The solution was magnetically stirred for 2 hours and ultrasonically dispersed for 2 hours to form a slurry, so that the mass ratio of carbon-supported platinum and Nafion in the suspension was 66:34.

[0035] (2) Spray the slurry obtained in (1) evenly on one side of the Nafion-211 membrane with an ultrasonic sprayer to form an anode catalytic layer, and dry it in a vacuum oven. The spraying time was 50 minutes, the temperature was 80° C., and the platinum loading was 0.2 mg / cm2.

[0036] (3) Add a carbon-supported ruthenium-based telluride (RuTe2 / C, the carrier is Vulcan-XC72R) catalyst into a mixed solution of deionized water and ethanol (volume ratio of 20:80) and then add a certain amount of 5% mass fraction of Nafion solution was magnetically ...

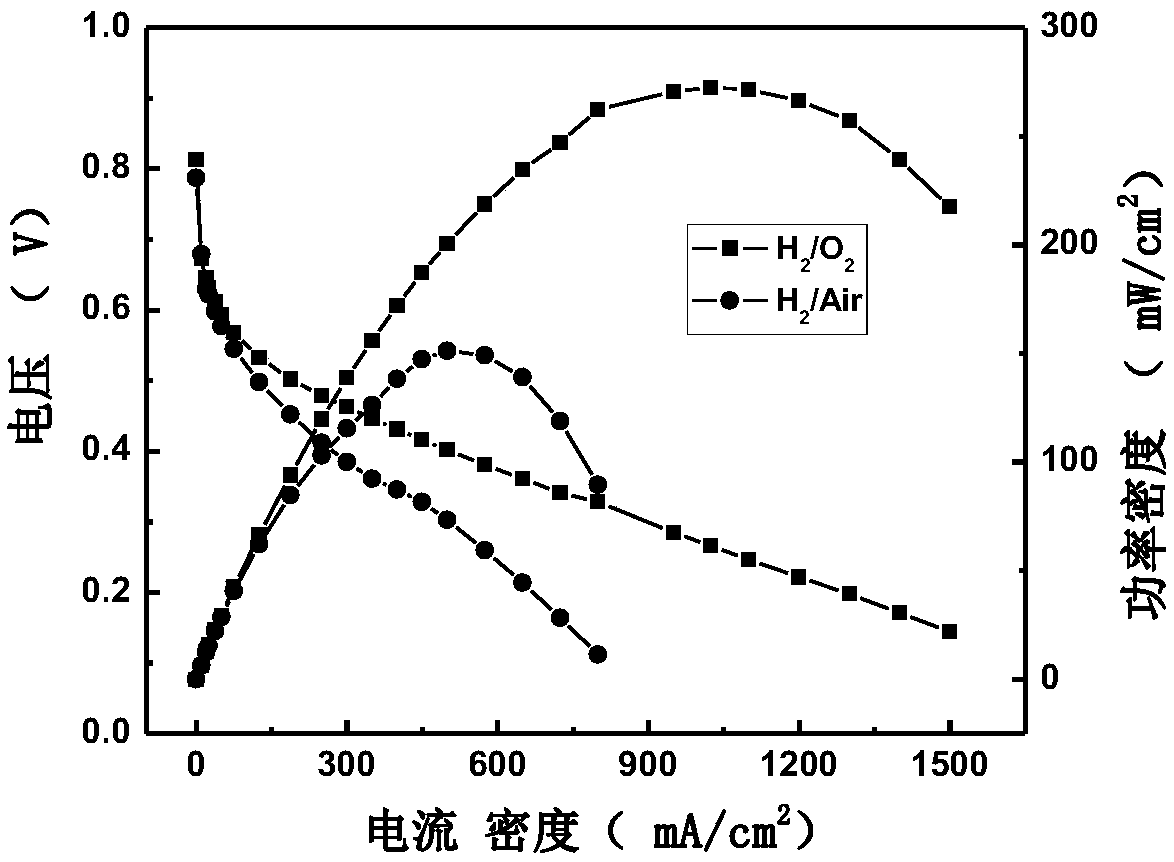

Embodiment 3

[0040] (1) The platinum mass fraction is 60%, and the carbon-supported platinum catalyst of Vulcan-XC72R is added to the mixed solution of deionized water and ethanol (volume ratio is 50:50), and then a certain amount of 5% mass fraction of Nafion is added. The solution was magnetically stirred for 1 hour, ultrasonically dispersed for 1 hour, and prepared into a slurry, so that the mass ratio of carbon-supported platinum and Nafion in the suspension was 70:30.

[0041] (2) Spray the slurry obtained in (1) evenly on one side of the Nafion-112 membrane with an ultrasonic sprayer to form an anode catalytic layer, and dry it in a vacuum oven. The spraying time was 60 minutes, the temperature was 75° C., and the platinum loading was 0.25 mg / cm2.

[0042] (3) Add a carbon-supported ruthenium-based telluride (RuTe2 / C, the carrier is BP2000) catalyst into a mixed solution of deionized water and ethanol (volume ratio of 50:50), and then add a certain amount of 5% Nafion solution by mas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com