Automobile transmission assembly fatigue life test bench

A technology of automobile transmission and fatigue life, which is applied in the field of automobile manufacturing, can solve the problems such as the long period of the bench debugging process, and achieve the effect of ensuring the accuracy of the coaxiality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

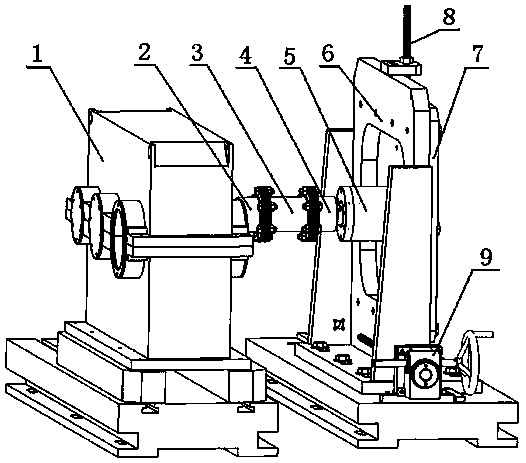

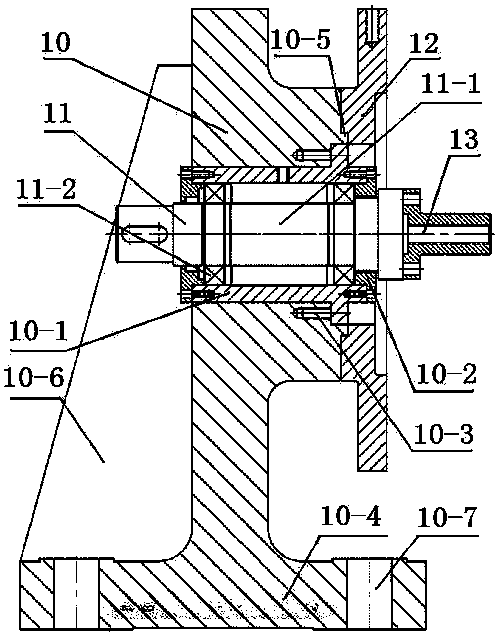

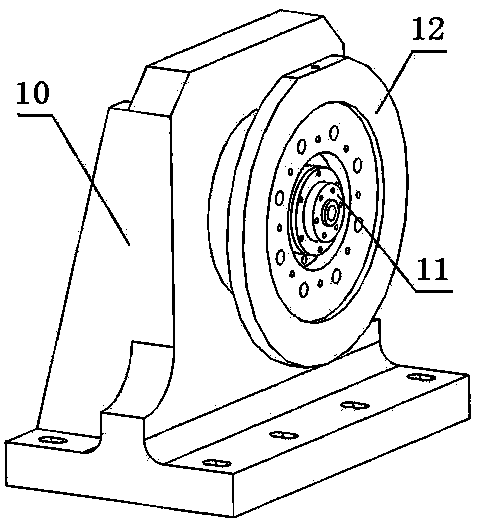

[0017] Such as Figure 1~3 The automobile transmission assembly fatigue life test bench shown in the figure includes a gearbox 1, a gearbox output flange 2, a coupling 3, a cylinder input flange 4, a cylinder assembly 11 and a support Assembly 10, the support assembly 10 includes a support body 10-4, the support body 10-4 is provided with a horizontal through hole, and the horizontal through hole is provided with a shaft sleeve 10-1, and the shaft sleeve 10-1 passes through the screw 10- 3 is fixed in the support body 10-4, the right end surface of the support body 10-4 has a cylindrical boss 10-5, and the boss 10-5 is connected with a groove that matches the boss 10-5. Mounting plate 12, mounting plate 12 is disc-shaped, and the depth of its groove is slightly greater than the height of boss 10-5, and its diameter is slightly greater than the outer dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com