Train traction motor bearing life testing machine

A traction motor and bearing life technology, applied in the direction of mechanical bearing testing, mechanical component testing, machine/structural component testing, etc., can solve the problems of low sensitivity, poor use effect, serious failure degree, etc. The effect of high discrimination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

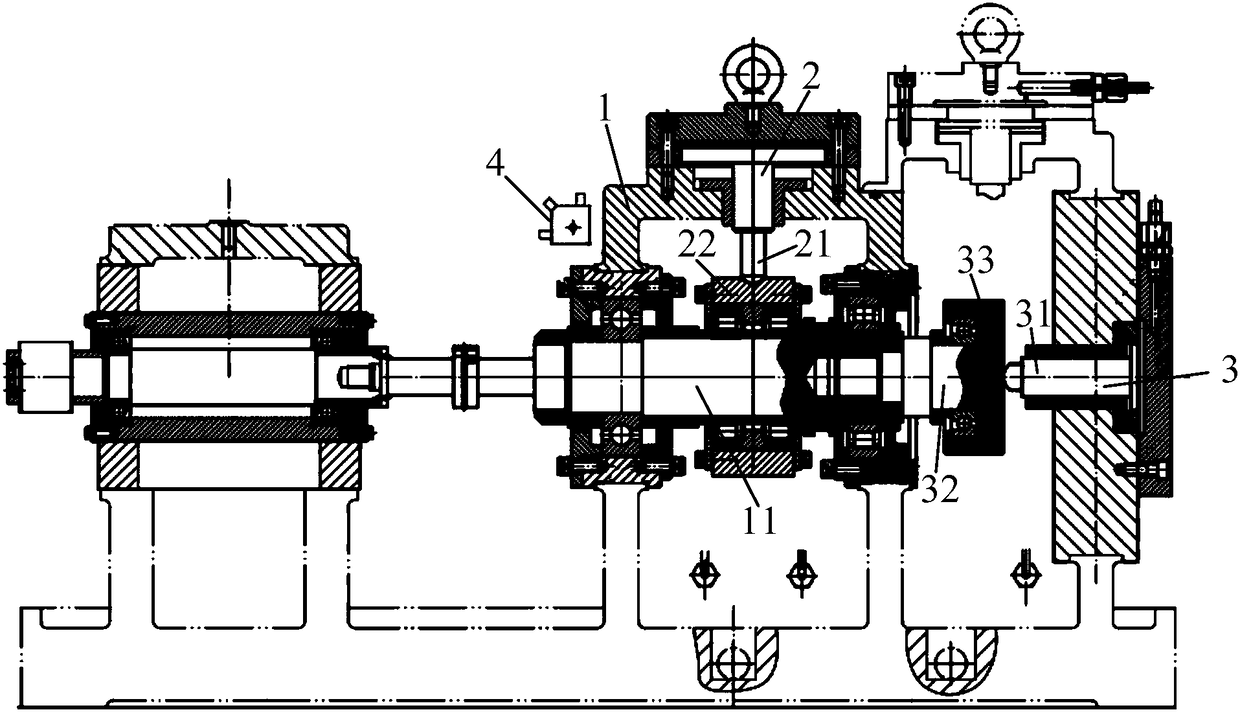

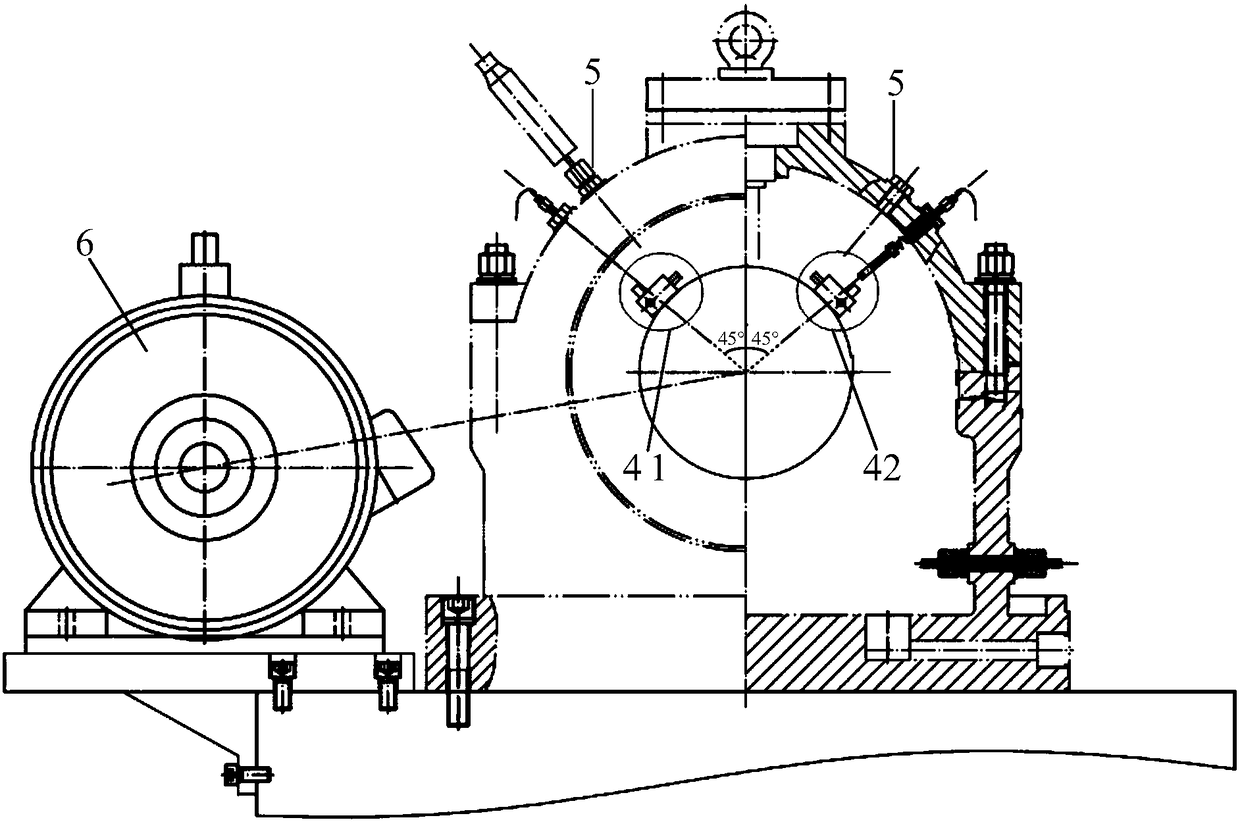

[0033] The core of this application is to provide a bearing life testing machine for train traction motors. On the basis of the conventional use of temperature sensors to obtain the corresponding real-time temperature data of the test bearings during use, a vibration sensor that can obtain real-time vibration data of the test bearings is also added. , so two different types of real-time data can be used to jointly characterize the fault characteristic data corresponding to the test bearing under different faults, and at the same time, it can also detect the change trend of the fault characteristic data of the same fault in different fault degrees in the entire fault cycle, and can get more Accurate and higher-discrimination fault characteristic data are used as fault criteria for subsequent judgments on whether the same fault exists. At the same time, in order to more realistically simulate the actual usage scenario, the present application arranges a tested bearing at both end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com