Assembled hanging bracket and assembling technology thereof

An assembly process and assembly technology, applied in the direction of pipeline supports, pipes/pipe joints/pipes, mechanical equipment, etc., can solve the problems of blind setting of hole spacing, cumbersome rods and connectors, and inflexible assembly of rod spacings. , to avoid the effect of heavy workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

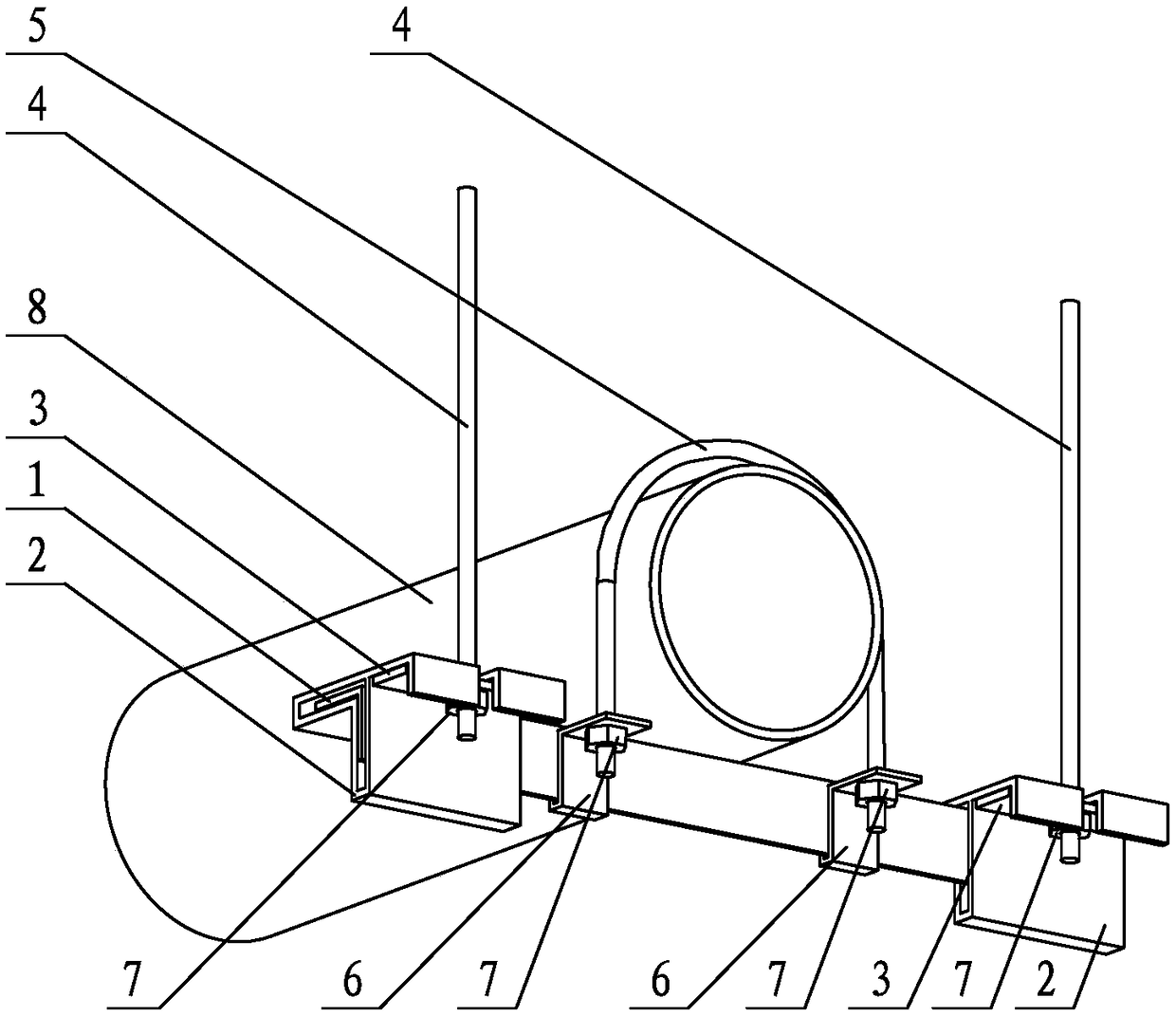

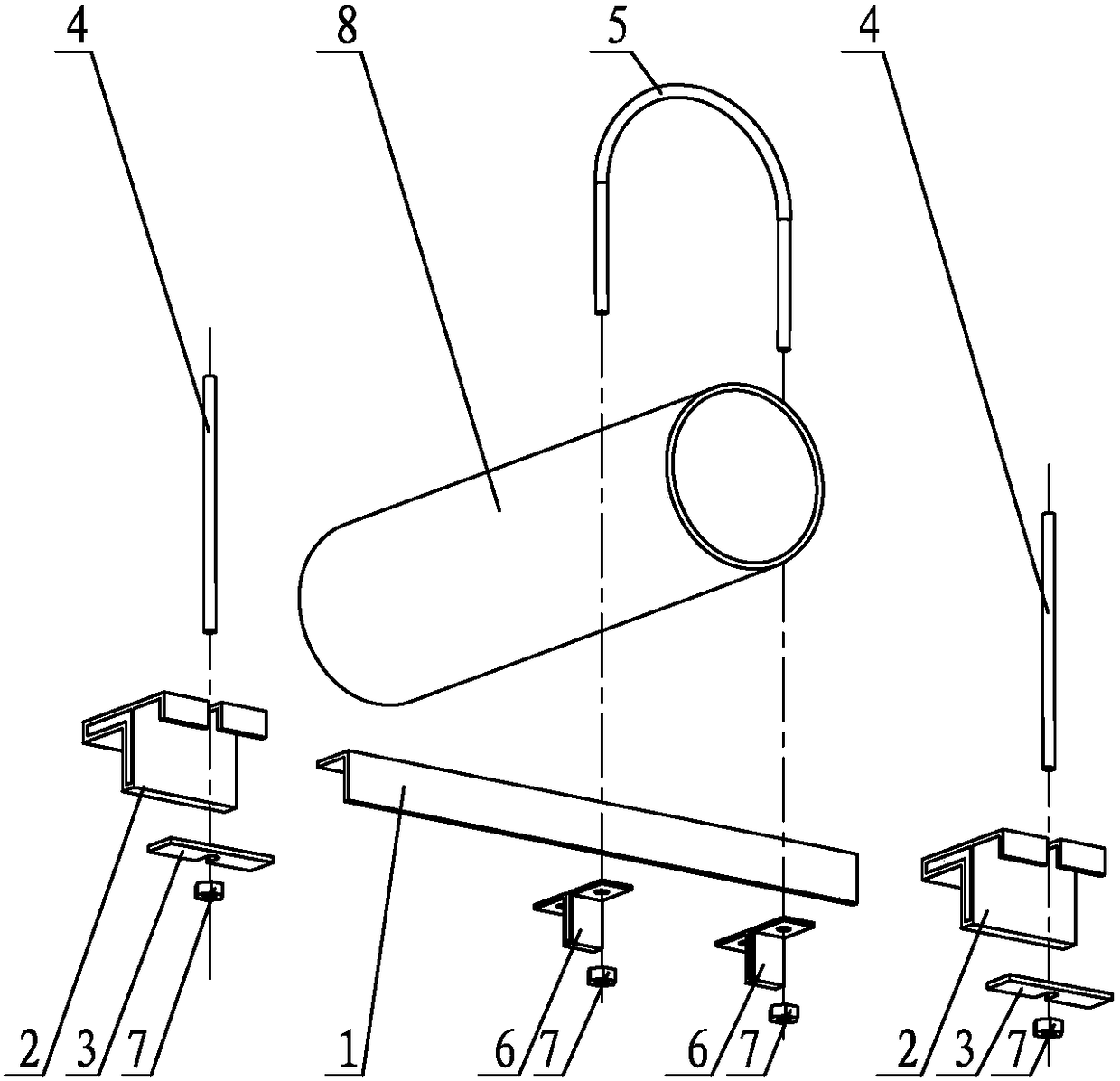

[0029] see Figure 1~4 , the present invention relates to an assembled hanger, the assembled hanger includes: a horizontal bar 1, a terminal connector 2, a hanger 4, a hoop 5, a clip 6 and a nut 7, the hanger 4 is detachably connected to both ends of the horizontal rod 1 through the end connector 2, the clamping member 6 is detachably clamped to the middle of the horizontal rod 1, and the hoop 5 clamps An object to be fixed 8 , and the two ends of the hoop 5 are respectively connected with the corresponding clips 6 and fixed by nuts 7 .

[0030] The fabricated hanger also includes a gasket 3, and the boom 4, the end connector 2, the gasket 3, and the nut 7 are sequentially connected.

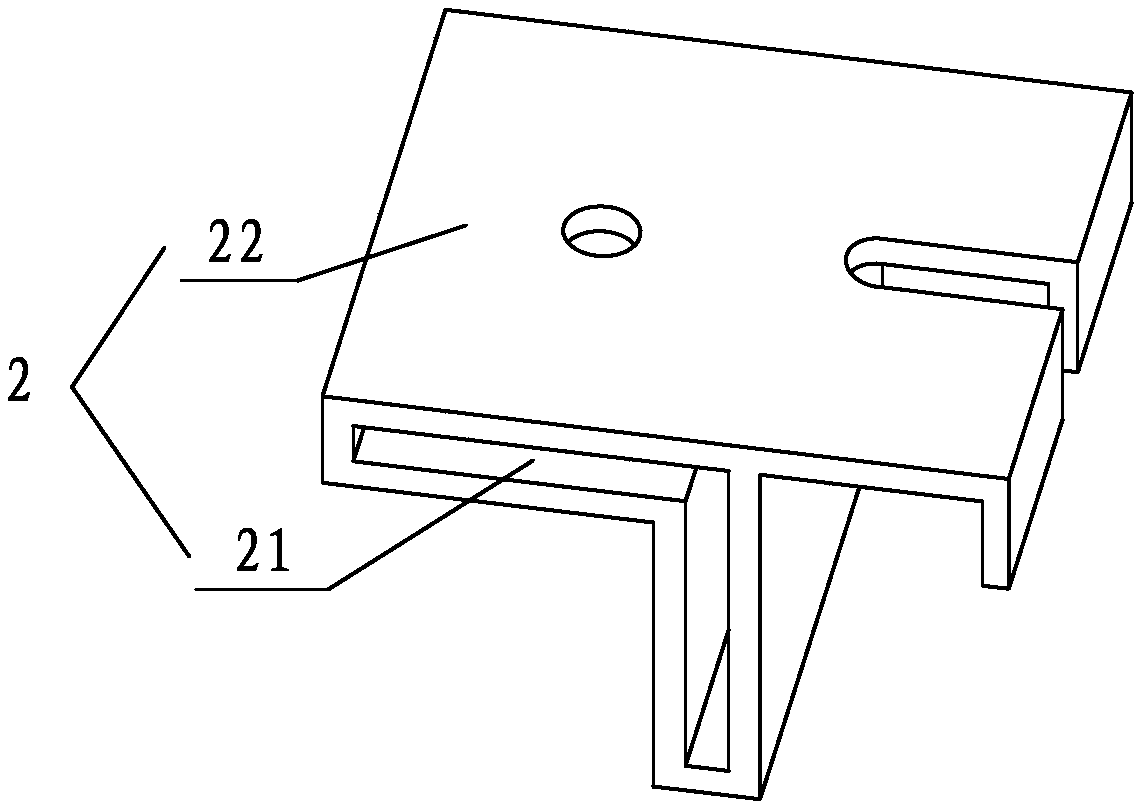

[0031] The section of the horizontal bar 1 is an inverted L-shaped bar, and the end connector 2 has a slot 21 and a horizontal connecting plate 22 that match the section shape of the horizontal bar. The two ends of the horizontal bar 1 It is detachably inserted into the corresponding slot 21 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com