Internally-reinforced composite butyl self-adhesive ethylene-propylene rubber waterproof coiled material and production method thereof

A waterproofing membrane, compound butyl technology, applied in rubber layered products, chemical instruments and methods, synthetic resin layered products, etc., can solve the problem of poor handling of the details of the waterproof layer, and achieve excellent viscosity-increasing properties. , Improve the composite quality, improve the effect of aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

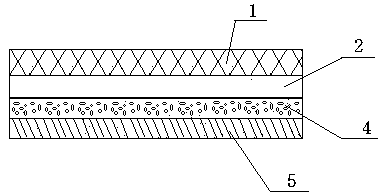

[0052] refer to figure 1 , this internally reinforced composite butyl self-adhesive ethylene-propylene rubber waterproof membrane is composed of a surface layer 1, a reinforcement layer 2, a base layer 3, a self-adhesive layer 4, and an anti-adhesive layer 5. The base layer 3 is compounded on both sides of the reinforcement layer 2 to form the base layer, the surface layer 1 and the base layer 3 are both ethylene-propylene rubber layers, the reinforcement layer 2 is metal punched mesh or fiber mesh cloth, and the self-adhesive layer 4 is butyl self-adhesive rubber layer or butyl hot melt adhesive, the anti-adhesive layer 5 is a PE isolation film; the metal punching screen is 2×4mm metal punching screen.

[0053] The components of surface layer 1 and base layer 3 are: 100 parts of binary ethylene propylene rubber; 80 parts of reinforcing agent; 40 parts of filler; 25 parts of plasticizer; 1.5 parts of active agent; 6 parts of tackifier 0.8 parts of accelerator; 1 part of vulca...

Embodiment 2

[0082] refer to figure 2 , this internally reinforced composite butyl self-adhesive ethylene propylene rubber waterproof membrane is composed of surface layer 1, reinforcement layer 2, self-adhesive layer 4, and anti-adhesive layer 5. The surface layer 1 is compounded on the reinforcement layer 2 constitutes the base layer, the surface layer 1 is an ethylene-propylene rubber layer, the reinforcement layer 2 is a metal punched mesh or fiber mesh cloth, and the self-adhesive layer 4 is a butyl self-adhesive rubber layer or butyl hot-melt adhesive, anti-adhesive Layer 5 is a PE isolation film; the metal punched and expanded mesh is 3×6mm metal punched and expanded mesh.

[0083] The components of surface layer 1 in parts by mass are: 100 parts of binary ethylene propylene rubber; 95 parts of reinforcing agent; 15 parts of filler; 20 parts of plasticizer; 1.7 parts of active agent; 8 parts of tackifier; 0.6 parts of curing agent; 1.2 parts of vulcanizing agent; 1.1 parts of anti...

Embodiment 3

[0112] This internally reinforced composite butyl self-adhesive ethylene-propylene rubber waterproof membrane is composed of surface layer 1, reinforcement layer 2, base layer 3, self-adhesive layer 4, and anti-adhesive layer 5. The surface layer 1, base layer 3 is compounded on both sides of the reinforcement layer 2 to form the base layer, the surface layer 1 and the base layer 3 are both ethylene-propylene rubber layers, the reinforcement layer 2 is metal punched mesh or fiber mesh cloth, and the self-adhesive layer 4 is a butyl self-adhesive rubber layer Or butyl hot-melt adhesive, the anti-adhesive layer 5 is a PE isolation film; the metal punching screen is 3×6mm metal punching screen.

[0113] The components of surface layer 1 and base layer 3 are: 100 parts of EPDM rubber; 100 parts of reinforcing agent; 25 parts of filler; 26 parts of plasticizer; 1.8 parts of active agent; 7 parts of tackifier parts; accelerator 0.6 parts; vulcanizing agent 1.2 parts; anti-aging agen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com