Hyperbranched polymer composite microspheres with core-shell structure, preparation method and application

A technology of hyperbranched polymer and composite microspheres, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of low strength, temperature difference resistance, prolonging the viscosity retention time of hyperbranched polymers, etc., which is not easy to achieve. Effects of water swelling, enhanced oil recovery, and good profile control and flooding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

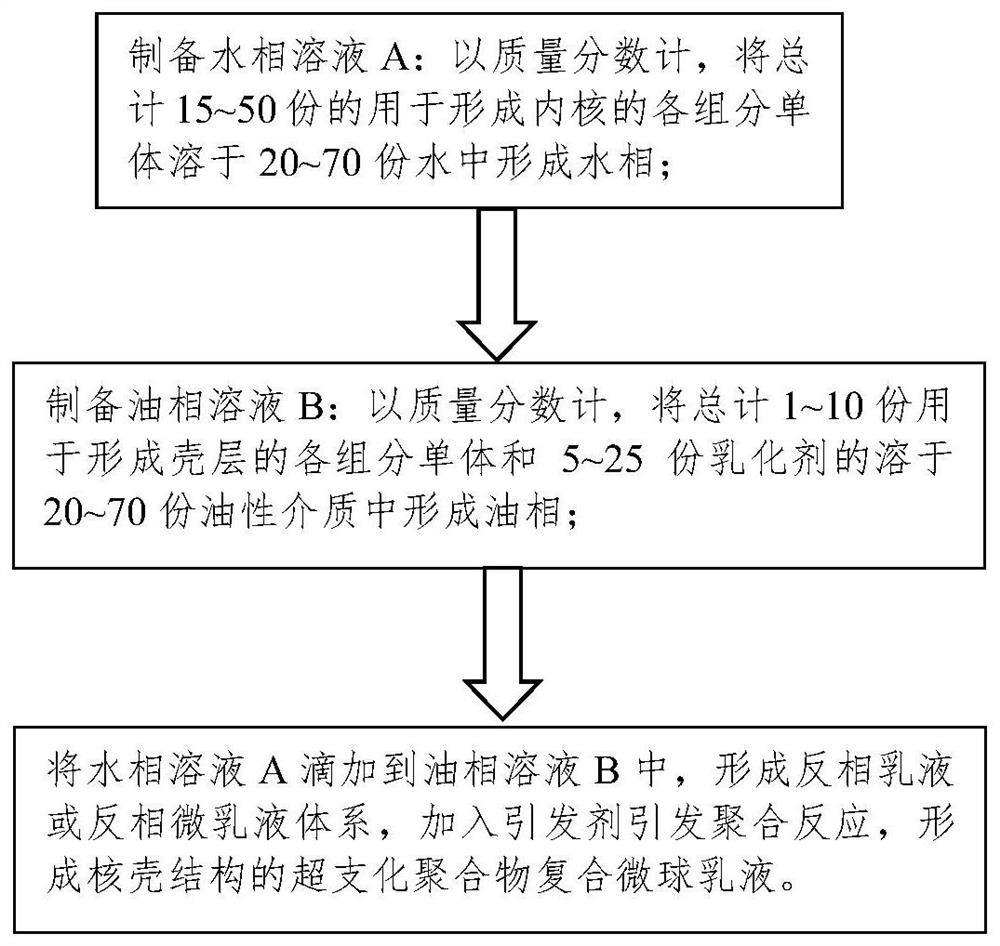

Method used

Image

Examples

Embodiment 1

[0044] Add 40 parts of white oil and 10 parts of fatty alcohol polyoxyethylene ether (3) and 3.5 parts of fatty alcohol polyoxyethylene ether (15 ), heat up to 45°C, after dissolving evenly, add 5.4 parts of styrene, 2.3 parts of vinyl acetate and 0.30 parts of divinylbenzene respectively, keep the temperature at 40°C, add 0.95 parts of branching agent polypropylene to 55 parts of deionized water After fully stirring and dissolving methacrylamide at 45°C, add 38 parts of acrylamide and 3.6 parts of dimethylaminopropyl acrylamide respectively, and dissolve evenly to obtain an aqueous phase. The oil phase is stirred at a speed of 400r / min, and the water phase is added dropwise to obtain a translucent emulsion. The air was replaced with nitrogen for 0.5 h, 2 mL of 2% ammonium persulfate aqueous solution and 3 mL of 2% sodium bisulfite were added dropwise, and the mixture was reacted at a constant temperature of 40° C. for 6 h to obtain a hyperbranched polymer microsphere emulsion...

Embodiment 2

[0046] In the four-port reactor equipped with reflux condenser, thermometer, stirrer and nitrogen replacement device, add 40 parts of white oil and 12 parts of fatty alcohol polyoxyethylene ether (3) and 4 parts of fatty alcohol polyoxyethylene ether (15 ), heated up to 45°C, and after dissolving evenly, added 6 parts of styrene, 3.5 parts of vinyl acetate and 0.30 parts of divinylbenzene, and kept the temperature at 40°C. Add 1.5 parts of branching agent polyacryl (N-methyl) methacrylamide to 40 parts of deionized water, stir and dissolve fully at 45°C, add 30 parts of acrylamide and 2.5 parts of methylol acrylamide respectively, dissolve After uniformity, the aqueous phase was obtained. The oil phase is stirred at a speed of 400r / min, and the water phase is added dropwise to obtain a transparent emulsion. The air was replaced with nitrogen for 0.5 h, 2 mL of 2% ammonium persulfate aqueous solution, and 3 mL of 2% sodium bisulfite were added dropwise, and reacted at a consta...

Embodiment 3

[0048] In the four-port reactor equipped with reflux condenser, thermometer, stirrer and nitrogen replacement device, add 55 parts of white oil and 7 parts of fatty alcohol polyoxyethylene ether (3), 3 parts of fatty alcohol polyoxyethylene ether (5 parts) ) and 3.5 parts of fatty alcohol polyoxyethylene ether (9), heated up to 45°C, and after they were uniformly dissolved, 3.5 parts of styrene, 3.0 parts of vinyl acetate and 0.25 parts of divinylbenzene were added respectively, and the temperature was kept at 40°C. Add 0.80 parts of branching agent polyacrylacrylamide to 35 parts of deionized water, stir and dissolve fully at 45°C, add 26 parts of acrylamide and 3 parts of hydroxyethyl methacrylate respectively, and dissolve evenly to obtain an aqueous phase. The oil phase is stirred at a speed of 400r / min, and the water phase is added dropwise to obtain a transparent emulsion. The air was replaced with nitrogen for 0.5 h, 2 mL of 2% ammonium persulfate aqueous solution and 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com