Preparation method of calcium carbonate with layered structure

A layered structure, calcium carbonate technology, applied in the nano field, can solve the problems of non-single crystal structure, long preparation time, cumbersome process, etc., and achieve the effects of uniform crystal form, simple preparation method and shortened time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

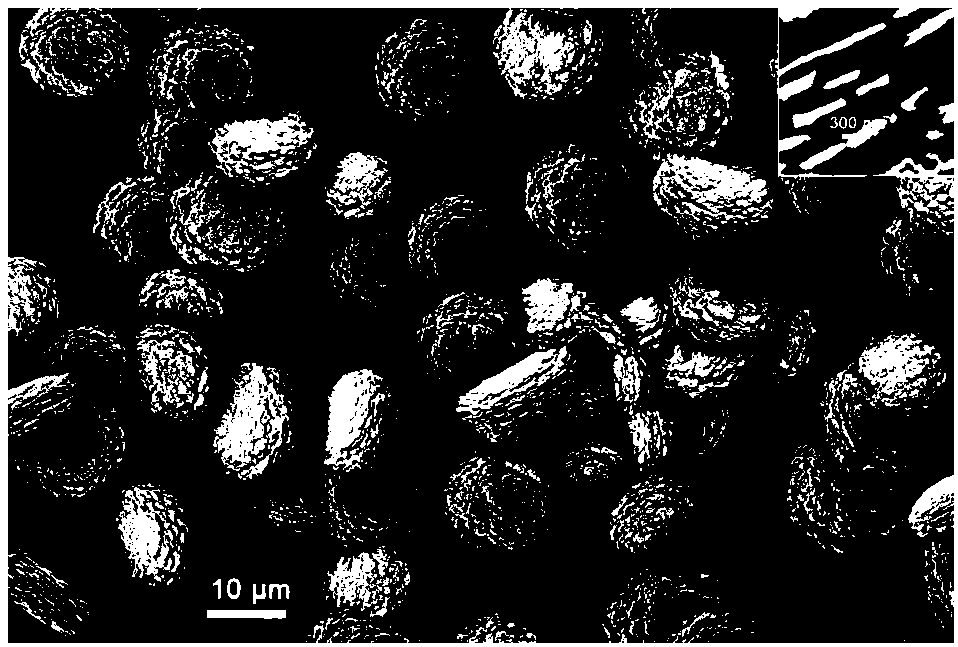

[0026] Embodiment 1, nanowire control has the preparation of layered structure calcium carbonate

[0027] In the desiccator, first put aluminum foil wrapped (NH 4 ) 2 CO 3 Medicine bottle, with two small holes pierced on the aluminum foil; then, put it into a 24-well plate, and add 100 microliters of 0.5mg / mL nanowires, 1.4mL of deionized water and 100 microliters of 200mM CaCl in three consecutive grooves 2 Solution, after mixing, put a circular cover glass with a diameter of 12mm in the solution, cover and seal the entire 24-well slot plate with aluminum foil and make a small hole in each of the three slots, and seal the desiccator. After 24 hours, the coverslips were removed and dried for observation.

Embodiment 2

[0028] Embodiment 2, nanowire control has the preparation of layered structure calcium carbonate

[0029] In the desiccator, first put aluminum foil wrapped (NH 4 ) 2 CO 3 Drug bottle, with two small holes pierced on the aluminum foil; then, put it into a 24-well slot plate, and add 125 microliters of 0.5mg / mL nanowires, 1.4mL of deionized water and 100 microliters of 200mM CaCl in three consecutive slots 2 Solution, after mixing, put a circular cover glass with a diameter of 12mm in the solution, cover and seal the entire 24-well slot plate with aluminum foil and make a small hole in each of the three slots, and seal the desiccator. After 24 hours, the coverslips were removed and dried for observation.

Embodiment 3

[0030] Embodiment 3, nanowire control has the preparation of layered structure calcium carbonate

[0031] In the desiccator, first put aluminum foil wrapped (NH 4 ) 2 CO 3 Drug bottle, with two small holes pierced on the aluminum foil; then, put it into a 24-well slot plate, add 50 microliters of 0.5mg / mL nanowires, 1.4mL of deionized water and 125 microliters of 200mM CaCl in three consecutive slots 2 Solution, after mixing, put a circular cover glass with a diameter of 12mm in the solution, cover and seal the entire 24-well slot plate with aluminum foil and make a small hole in each of the three slots, and seal the desiccator. After 24 hours, the coverslips were removed and dried for observation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com