Bag and suitcase cloth roll separating device facilitating cutting

A cutting device, luggage technology, applied in the directions of transportation and packaging, winding strips, thin material processing, etc., can solve the problems of inability to cut, easy to skew when dividing the roll, etc., to ensure the winding effect, ensure cleanliness, and cut Mouth smooth and neat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

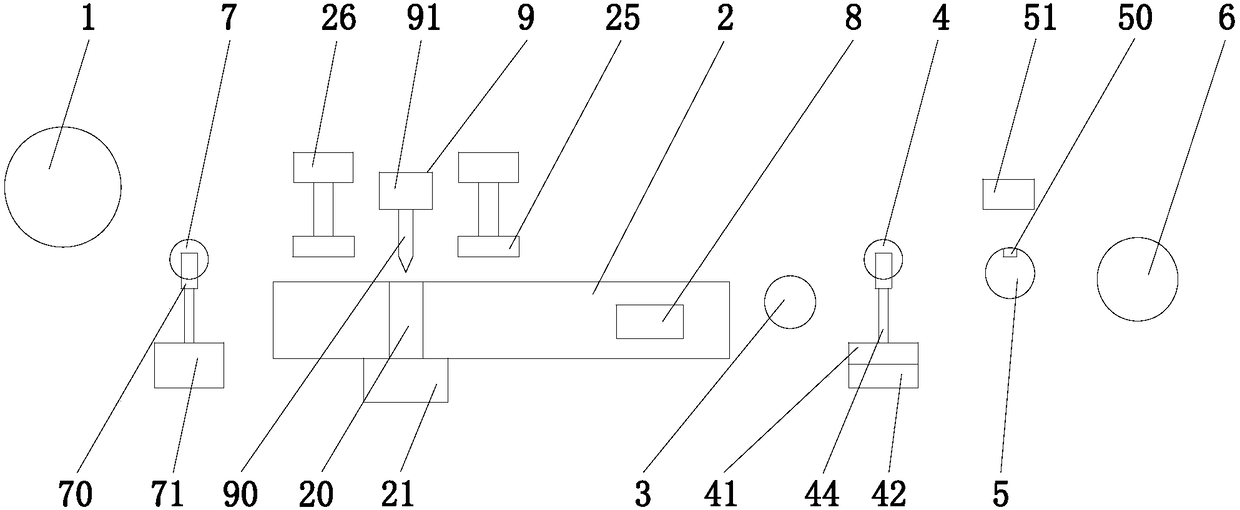

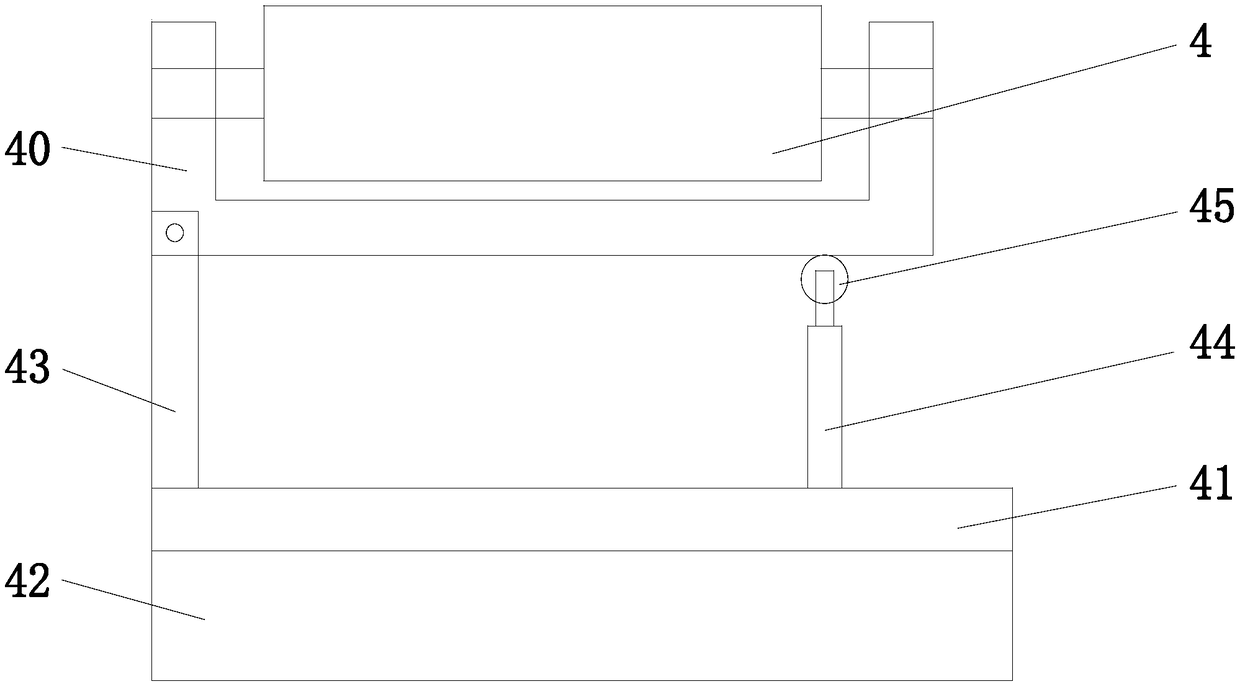

[0015] refer to figure 1 and figure 2 , a kind of bag cloth unwinding device that cuts conveniently of the present invention, comprises cutting table 2, cloth feeding mechanism 1, meter counter 3, deviation correcting stick 4, deviation measuring stick 5, first mounting frame 40, winding mechanism 6, cutting Device 9, control device 8, the cloth feeding mechanism 1, cutting table 2, meter counter 3, deviation correcting stick 4, deviation measuring stick 5, and winding device are arranged in sequence from left to right, and the cutting device 9 is located on the cutting table 2, the cutting table 2 is provided with a through groove 20 compatible with the cutting device 9, and two pressing plates 25 are arranged above the cutting table 2, and the two pressing plates 25 are located on the left and right sides of the through groove 20 respectively. The top of 25 is fixed with a first lifting device 26, and the deviation correcting stick 4 is installed on the first mounting fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com