Open caisson structure applied to narrow zone and construction method of open caisson structure

A technology for narrow areas and construction methods, which is applied in infrastructure engineering, underwater structures, artificial islands, etc., can solve the problems of surrounding soil disturbance, inconsistent settlement speed, inconvenient scaffolding, etc., and achieves convenient pouring process and construction. , the effect of good structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] refer to figure 1 , the caisson structure applied in the narrow area includes the caisson foundation pit formed by excavating downward layer by layer, each layer of the caisson foundation pit is a caisson foundation pit unit 1, and evenly An anchor piece 2 is provided, and an annularly distributed reinforcement cage 3 is arranged on the inner peripheral side of the caisson foundation pit unit 1, and the reinforcement cage 3 and the anchor piece 2 are fixedly connected to each other. There is an annular concrete shaft wall 4 poured outside the anchor piece 2 and the reinforcement cage 3, and the adjacent two layers of annular concrete shaft walls 4 are stacked up and down, and a concrete bottom cover 11 is provided at the bottom of the caisson foundation pit unit 1 at the bottom.

[0047] Compared with the existing caisson construction method, this application can carry out the construction layer by layer, and the height of each layer can be controlled at 100-160cm, so t...

Embodiment 2

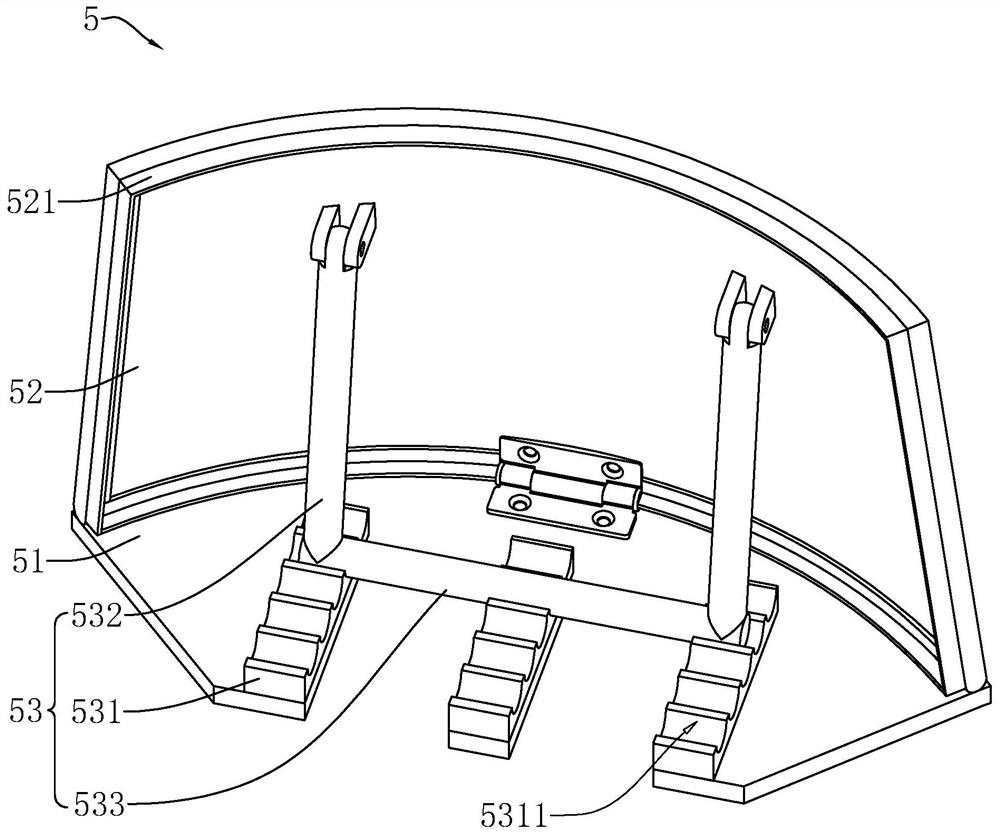

[0063] refer to figure 2 , image 3 The difference between embodiment 2 and embodiment 1 is that the caisson structure applied in narrow areas also includes auxiliary pouring units 5, and multiple auxiliary pouring units 5 are combined to form a pouring formwork, which makes the pouring process more convenient.

[0064] The auxiliary pouring unit 5 comprises a bottom support 51 horizontally supported on the ground, an arc formwork 52 vertically hinged on the upper surface of one side of the bottom support 51, and an arc formwork 52 arranged between the bottom support 51 and the arc formwork 52 for An angle adjustment assembly 53 for adjusting the angle of inclination of the arc formwork 52.

[0065] The bottom support member 51 is a flat plate structure up and down, and its side corresponding to the arc formwork 52 is arc-shaped, matching the curvature of the arc formwork 52 . The arc formwork 52 is hinged to the bottom support 51 through hinges, its arched surface is used ...

Embodiment 3

[0073] refer to Figure 4 The difference between Embodiment 3 and Embodiment 2 is that the caisson structure applied in narrow areas also includes elastic fixing components 54 for fixing two adjacent arc-shaped templates 52 .

[0074] The elastic fixing assembly 54 includes a fixed seat 541 and an elastic clamping seat 543 which are respectively fixedly connected to both sides of the concave surface of the arc template 52, and an elastic clamping seat 543 which is rotatably connected to the fixed seat 541 and can be connected to the adjacent arc template 52. 543 is the wrench 542 that is snapped in elastically.

[0075] The fixing seat 541 is rod-shaped, and one end is vertically fixedly connected to the arc template 52 . The handle 542 is provided with a through hole at the position corresponding to the fixed seat 541, and is connected to the fixed seat 541 by rotation through the through hole. The wrench 542 can only rotate around the axis of the fixed seat 541 relative to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com