Method and mechanism for overturning paper bag clips

A flipping mechanism and paper bag technology, applied in the direction of flipping objects, transportation and packaging, pile separation, etc., can solve the problems of no automatic flipping paper bag clips, etc., and achieve the effect of reducing the work intensity of workers, ensuring quality, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to better understand the present invention, the implementation of the present invention will be further described below with reference to the accompanying drawings and examples.

[0055] As attached Figure 1~Figure 8 As shown, a method for turning over a paper bag clip is implemented, and the turning method includes:

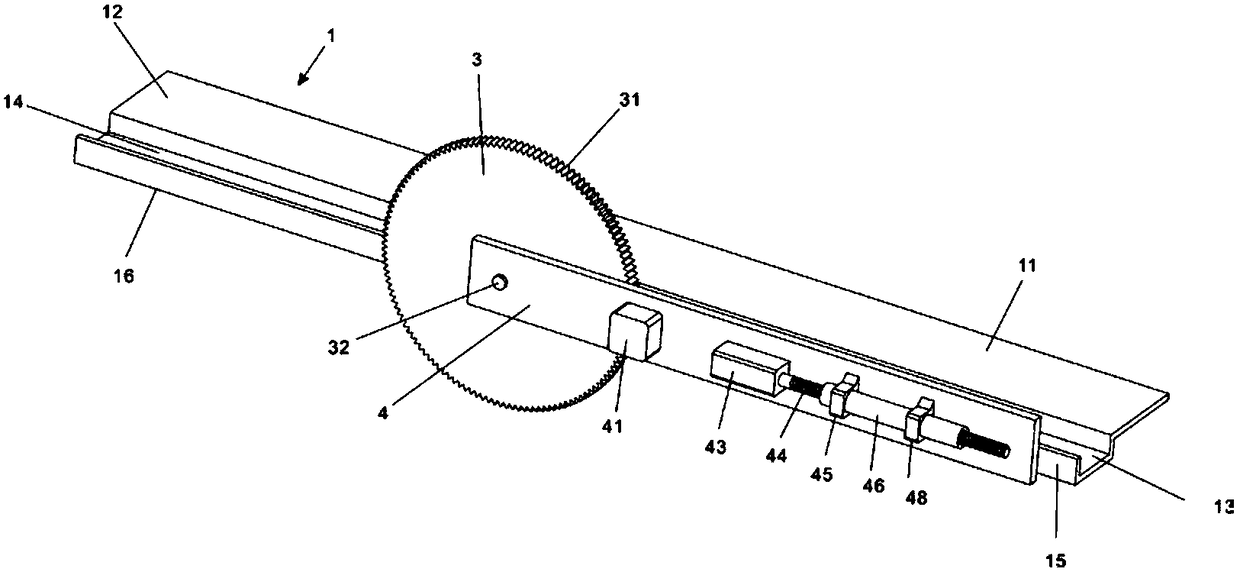

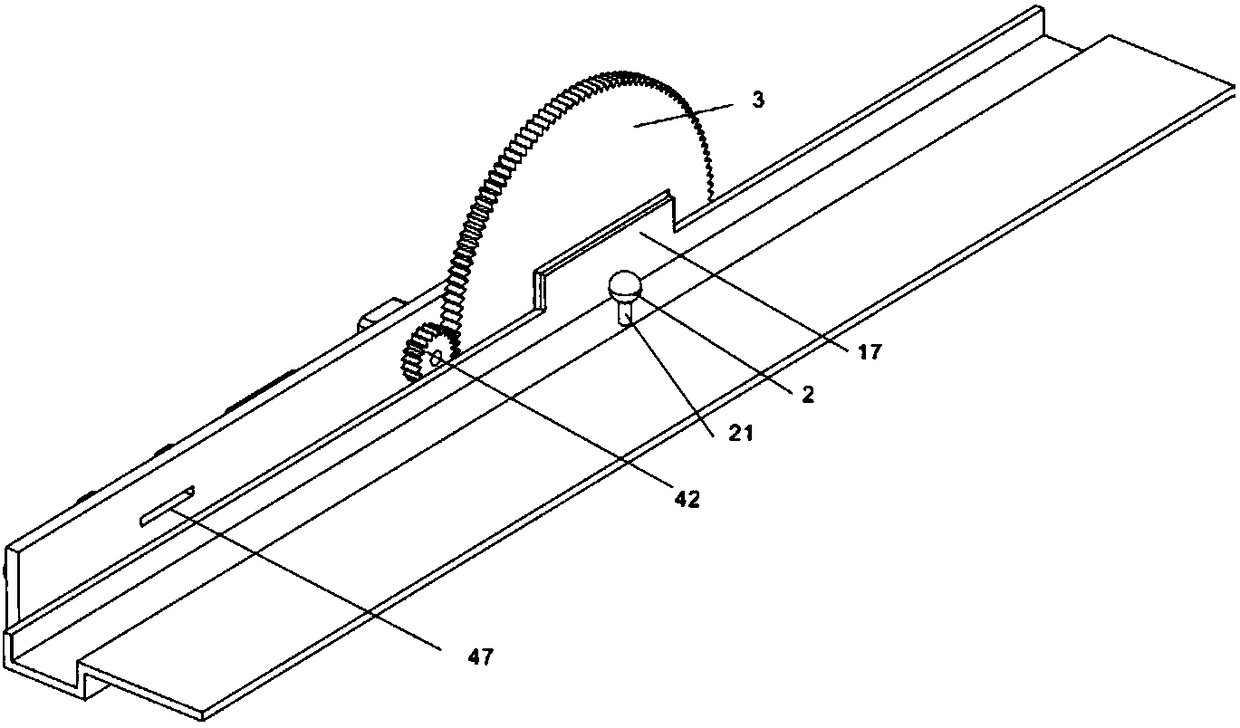

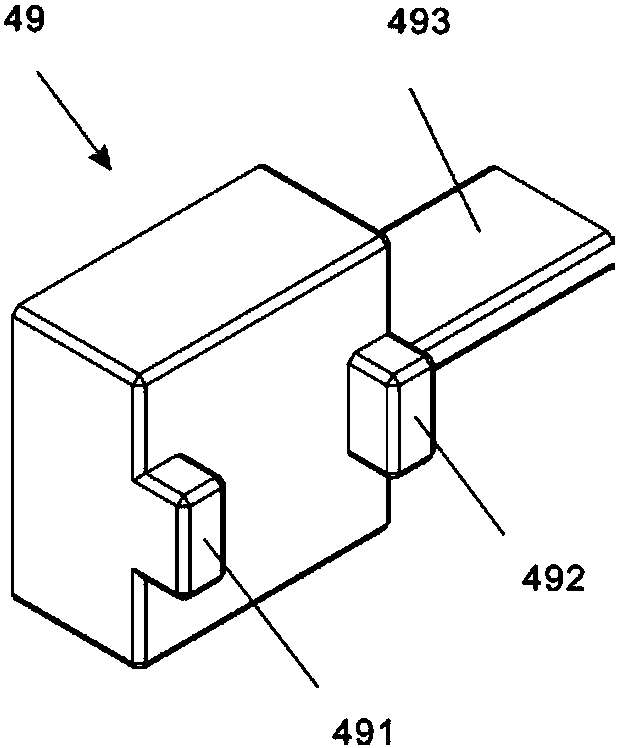

[0056] Step 1. First set up a fixture base 1, and then set a left platform 11, a right platform 12, a left paper bag clip chute 13 and a right paper bag chute 14 on the fixture base 1. The left platform 11 is used to place the quilt The clamped A side facing up paper bag 6; the right platform 12 is used to place the clamped B facing up paper bag 6; the left paper bag clamping chute 13 and the right paper bag chute 14 connect the left platform 11 and the right platform 12 ;

[0057] Step 2. Next, a frame reinforcement part 17 is provided on the left frame 15 of the left paper bag clip chute 13 and the right frame 16 of the right paper bag chute 14, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com