Tableware packaging machine

A packing machine and tableware technology, which is applied in packaging, packaging protection, transportation and packaging, etc. It can solve the problems of defective products, large differences in the positions of tableware and paper towels, and the inability to pack uniformly, so as to achieve convenient packaging and reduce The effect of packing, the effect of increasing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

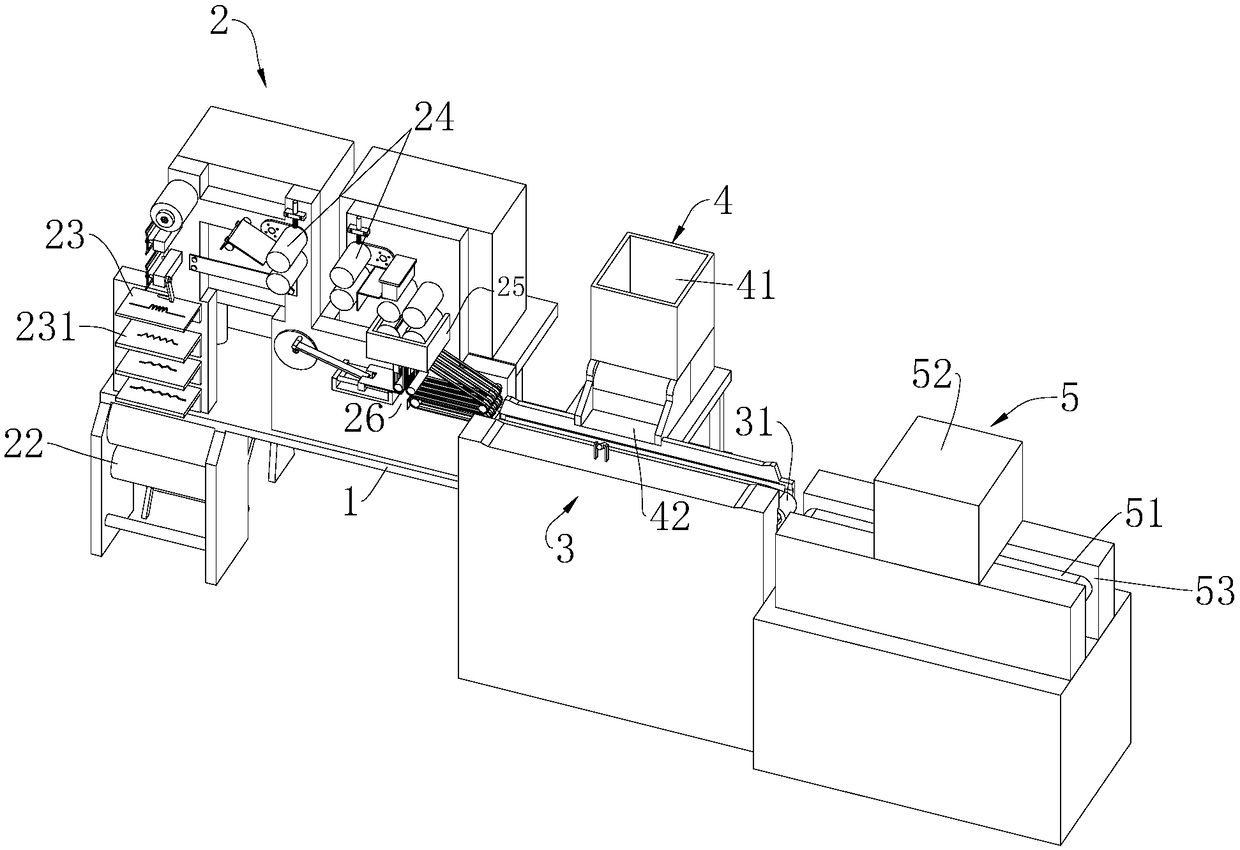

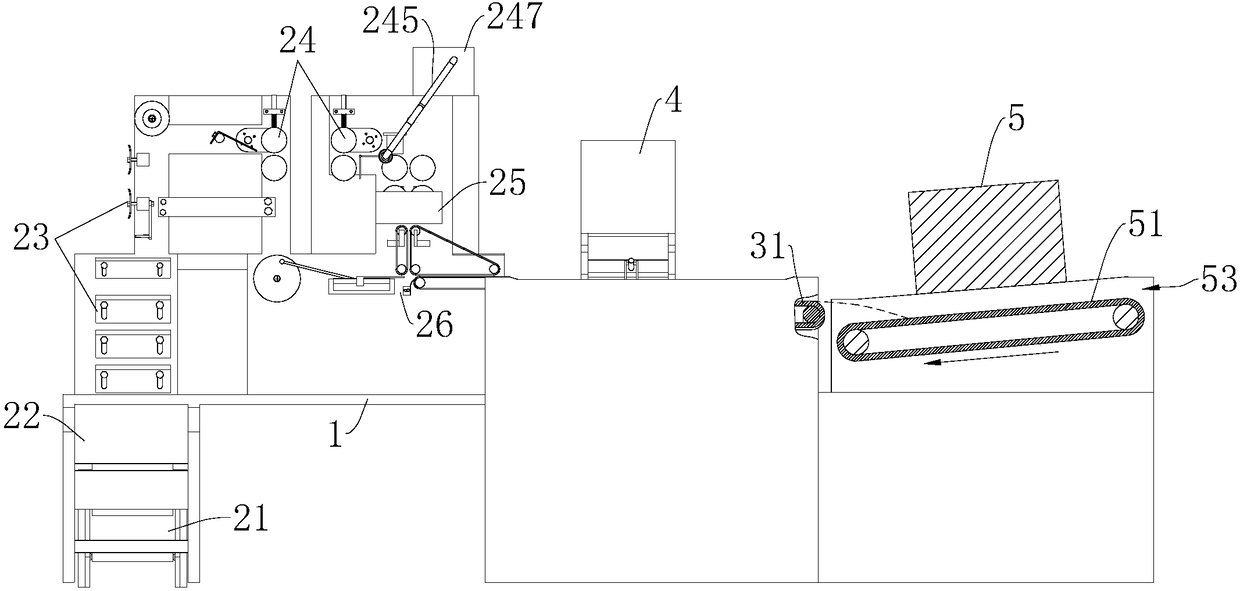

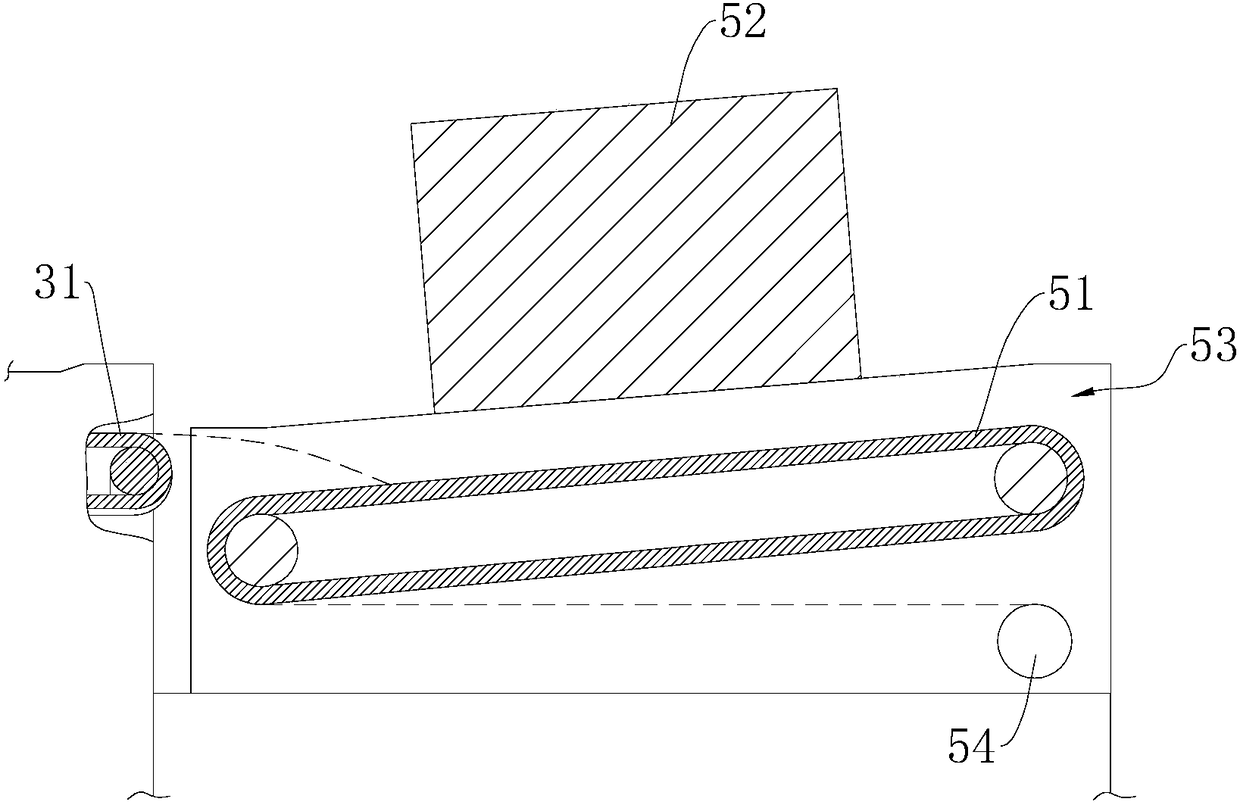

[0043] A tableware packaging machine, comprising a frame 1, a paper folding mechanism 2 sequentially arranged on the frame 1, a first conveying part 3, a packing mechanism 5, and a chopstick feeding machine 4 arranged on the first conveying part 3, the packing mechanism 5 includes a packaging machine 52 and a second conveyor belt 51 for accepting tableware, the second conveyor belt 51. is arranged obliquely, and the second conveyor belt 51. is close to the height of one end of the first conveyor belt 31, which is lower than the second conveyor belt 51. One end of finished product outlet 53 .

[0044] The second conveyer belt 51 that is provided with inclination plays a blocking effect, before the chopsticks 7 fall on the second conveyor belt 51., stop the chopsticks 7 from moving forward, prevent the chopsticks 7 from directly rushing into the working range of the packer. When the chopsticks 7 fell on the second conveyor belt 51., due to the inclined second conveyor belt 51., ...

Embodiment 2

[0049] The structure of the tableware packing machine provided in this embodiment is as shown in the figure.

[0050] This tableware packaging machine comprises a frame 1, a paper folding mechanism 2 sequentially arranged on the frame 1, a first conveying part 3, a packaging mechanism 5, and a chopstick feeding machine 4 arranged on the first conveying part 3, the first conveying Part 3 includes a first conveyor belt 31, the supply port 42 of the chopsticks supply machine 4 extends to the top of the first conveyor belt 31, and the frame 1 is provided with a pressing piece 33, the pressing piece 33 straddles the first conveyor belt 31, and one end of the pressing piece 33 is fixed on On the frame 1 , the other end straddles the first conveyor belt 31 and rides on the supply port 42 .

[0051] The pressing sheet 33 in this solution organizes the table chopsticks 7 to eject from the first conveyor belt 31, reducing the generation of incomplete and defective products.

[0052] Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com