High-precision human model printing system and printing method

A human body model and printing system technology, applied in the field of 3D printing, can solve problems such as high cost, long working hours, and low efficiency, and achieve the effect of reducing printing errors and optimizing printing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

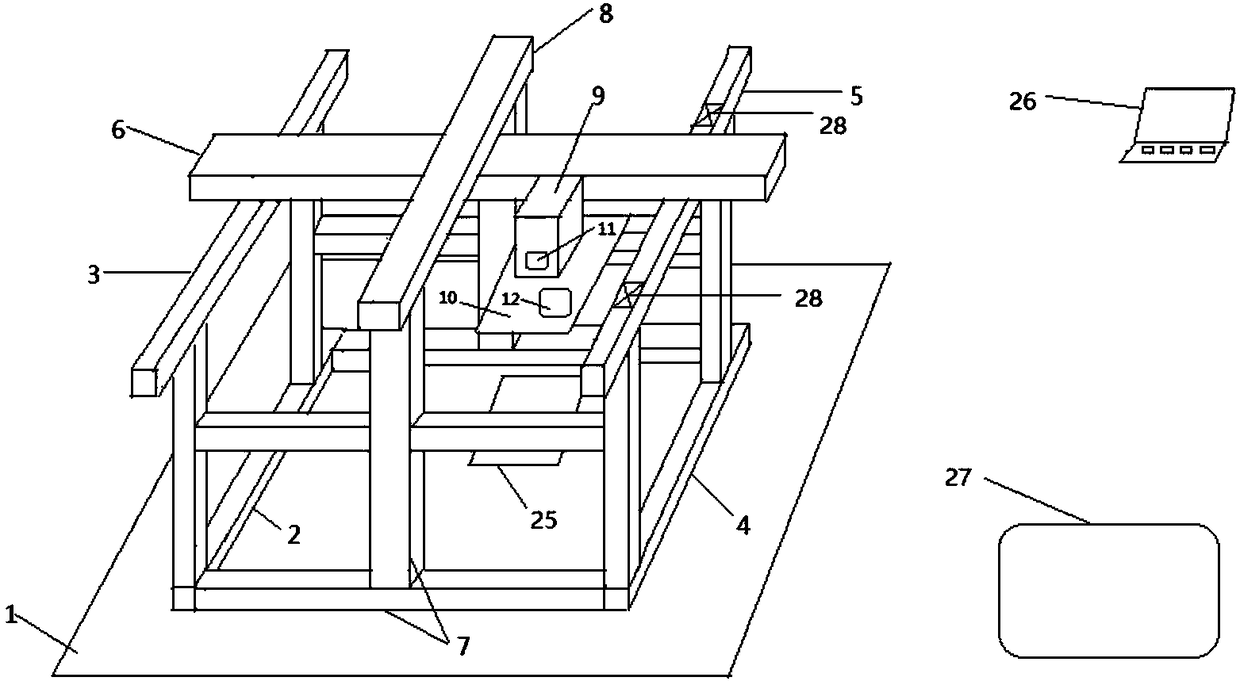

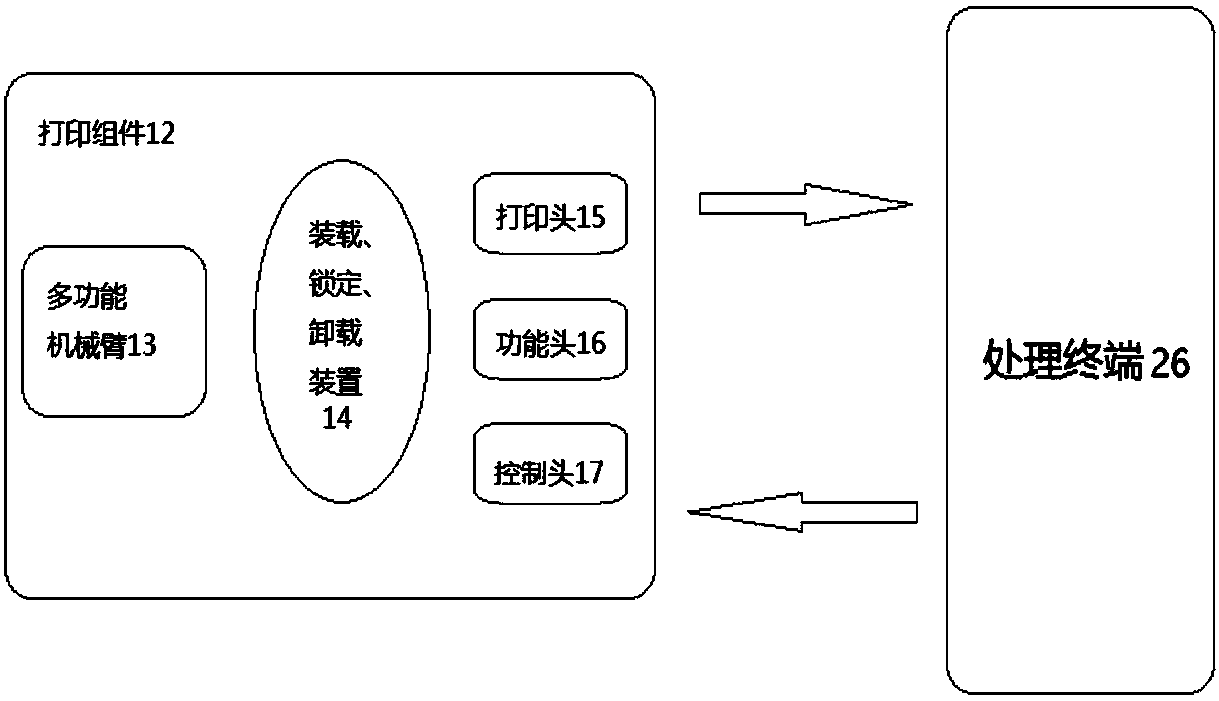

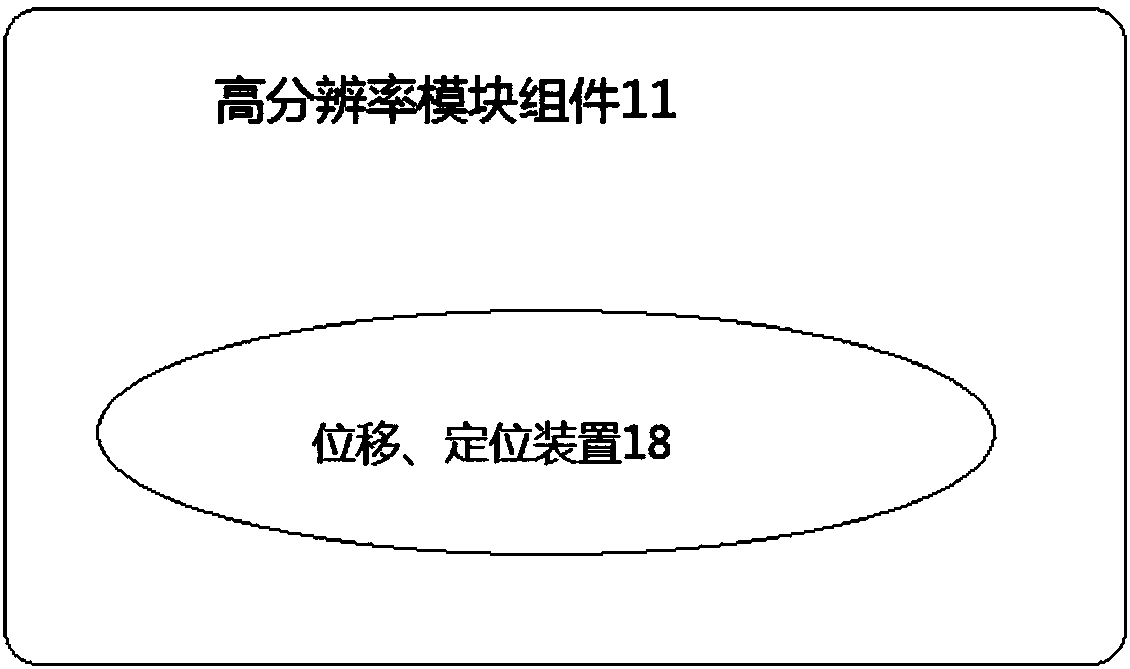

[0028] First introduce the system overview of the present invention. The components of the system in the figure include: system platform 1, first support bracket 2, X-direction linear slide rail 3, second support bracket 4, X-direction linear slide rail 5, and Y-direction linear slide rail. Sliding table module 6, third support frame 7, X direction linear sliding table module 8, Z direction linear sliding table module 9, low precision and low resolution module assembly 10, high precision and high resolution module assembly 11, printing assembly 12. Multifunctional mechanical arm 13, loading and locking and unloading device 14, printing head 15, functional head 16, control head 17, displacement device and positioning device 18, automatic focus system 19, focusing ultraviolet light head 20, infrared light head 21, electron beam Focusing curing head 22, ultrasonic head 23, controllable device 24, loading platform 25, processing terminal 26, raw material system 27, IP camera 28, 3D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com