Calibration device and calibration method for large-load bolt fastening tool

A calibration device and large-load technology, applied in the direction of motor tools, hand-held tools, manufacturing tools, etc., can solve the problems of no measurement mechanism verification capability or calibration device, direct accuracy and reliability, and affect bolt fastening, etc., to achieve the realization of quantitative The effects of value traceability, safe operation, and convenient measurement and calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

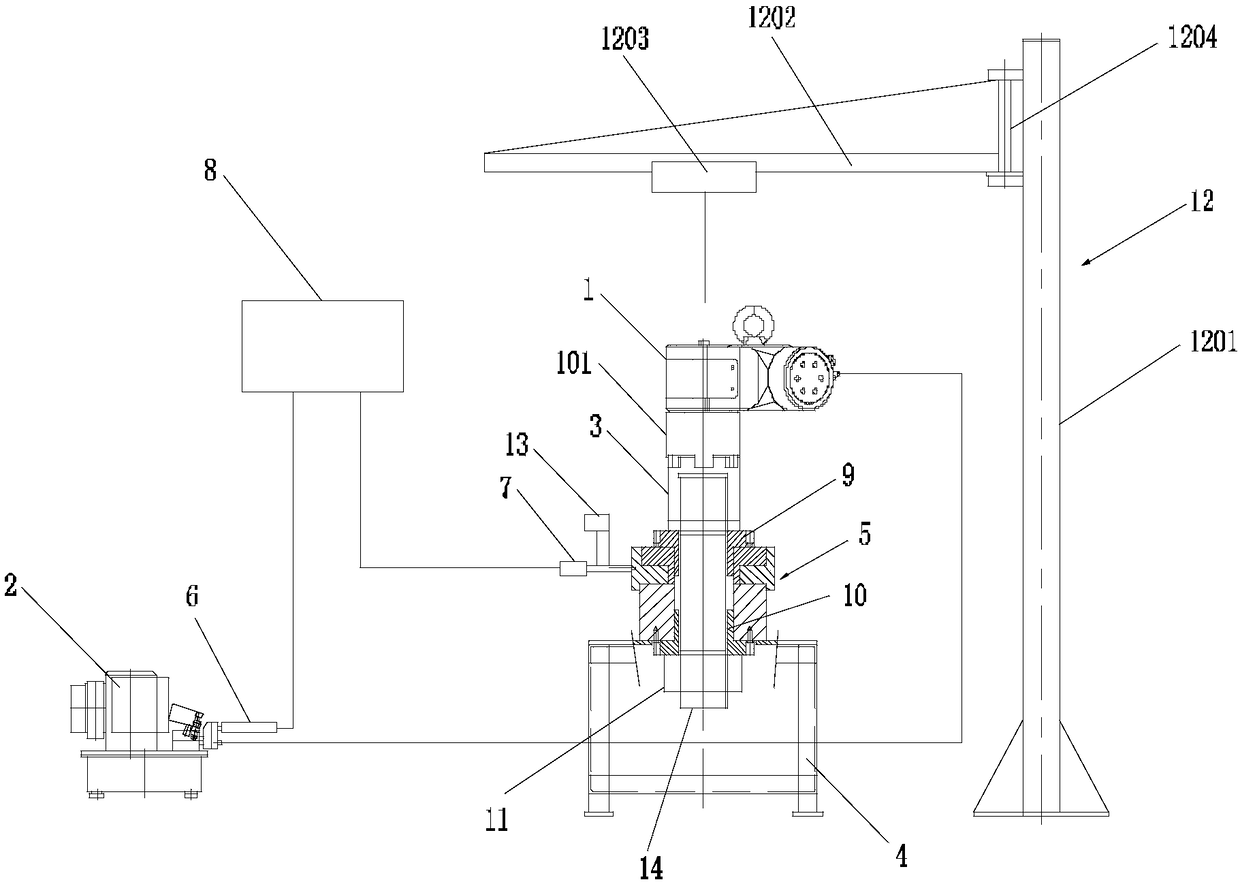

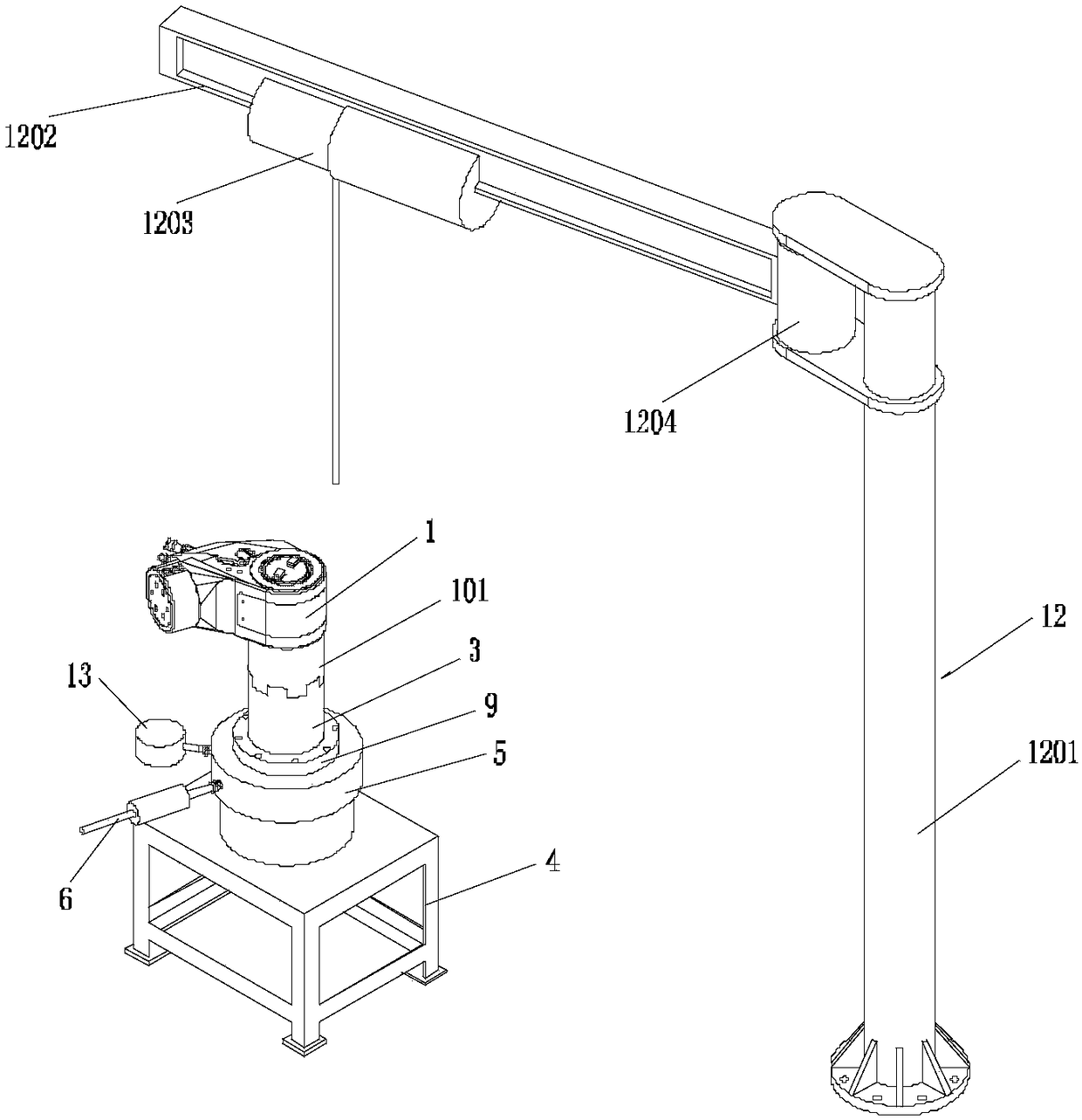

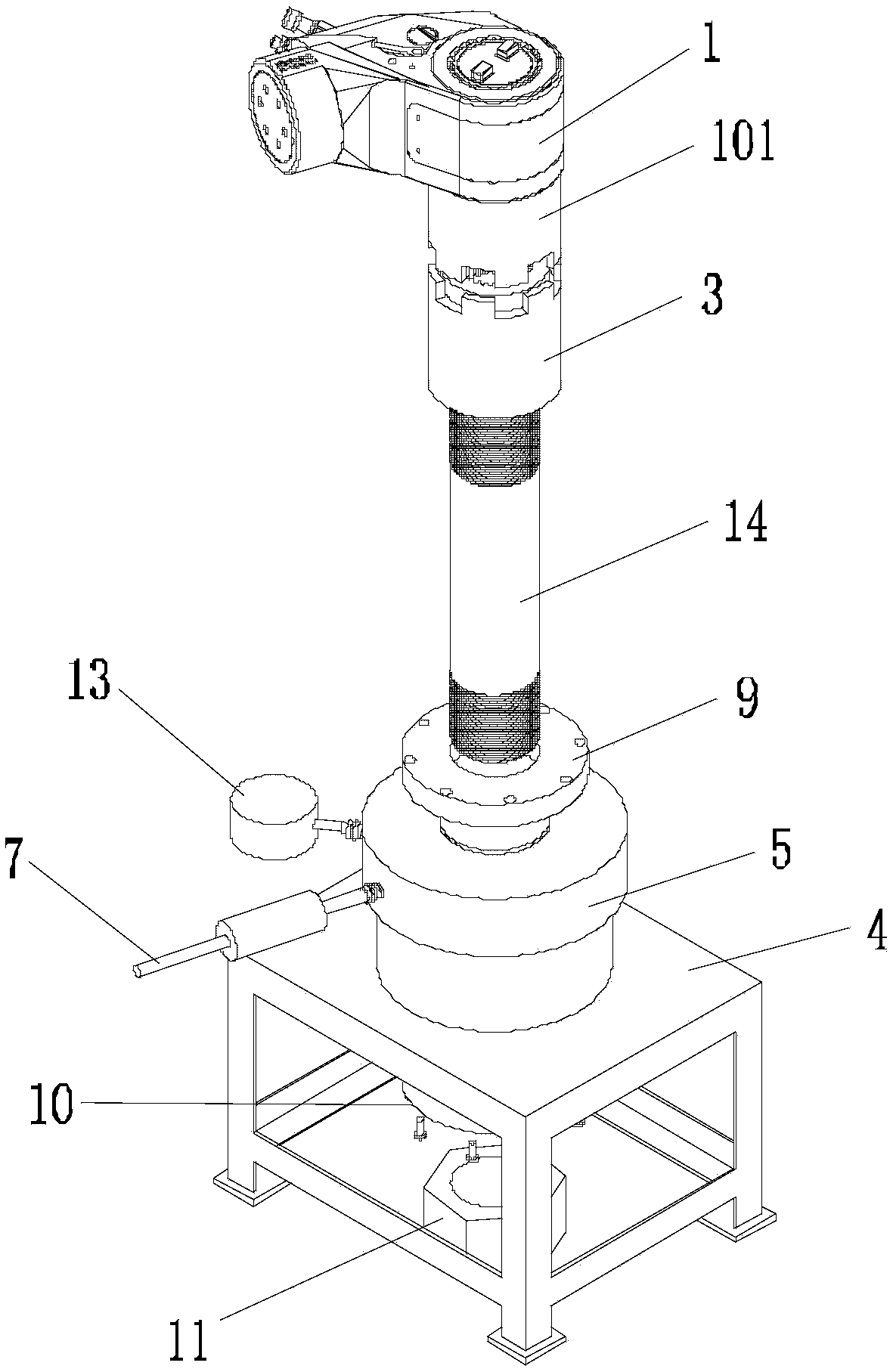

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0032] like Figure 1 to Figure 4 As shown, a fastening tool for large-load bolts includes a hydraulic wrench 1 that stretches the bolt 14 to be processed along its axial direction, a hydraulic pump 2 connected to the hydraulic wrench 1 through a high-pressure pipe, and one end connected to the hydraulic wrench 1 and the other. One end is connected with the tension nut 3 of the bolt 14 to be processed. The tension nut 3 includes an inner threaded sleeve 301 threadedly connected with the bolt 14 to be processed and an outer rotating sleeve 302 sleeved outside the inner threaded sleeve 301 , the inner threaded sleeve 301 is threadedly connected with the outer rotating sleeve 302 . One end of the outer rotating sleeve 302 is provided with an assembly structure for connecting with the hydraulic wrench 1 . Specifically, the hydraulic wrench 1 includes a nut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com