Movable dust removing vehicle

A dust removal vehicle and mobile technology, applied in the direction of cleaning method using gas flow, cleaning method and utensils, chemical instruments and methods, etc., can solve the problems such as inconvenient cleaning effect, achieve good practicability, convenient and flexible location, Convenient and flexible adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

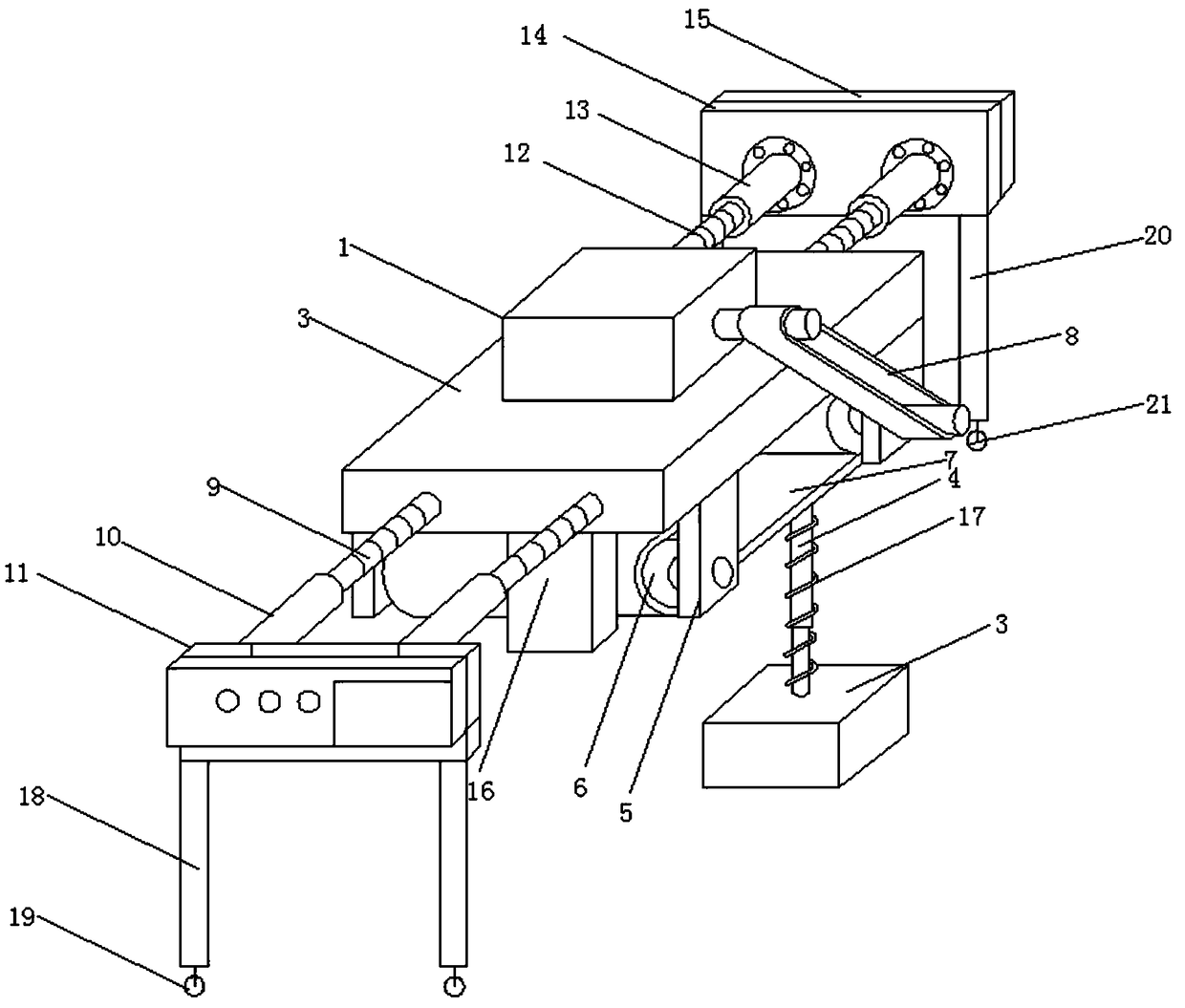

[0020] Such as figure 1 The mobile dust removal vehicle shown includes a traveling mechanism, a control mechanism, a drive motor 1, an assembly seat 2 and at least one set of dust collection mechanisms 3, and the control mechanism and drive motor 1 are fixed on the upper surface of the assembly seat 2, and the suction The dust mechanism 3 is located under the assembly seat 2, and the dust removal vehicle also includes two sets of fixed frames 5, two sets of rotating shafts, two sets of rotating rollers 6, a first transmission belt 7, a second transmission belt 8, and two sets of first threaded connecting rods 9. Two groups of first threaded connecting pipes 10, first fixing parts 11, two groups of second threaded connecting rods 12, two groups of second threaded connecting pipes 13 and second fixing parts 14, and the fixing frames 5 are arranged along the two sides of the assembly seat 2 respectively. The side width direction is set, the fixed frame 5 is also provided with two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com