Expanded graphite-based composite material and preparation method thereof

A technology of expanded graphite and composite materials, applied in chemical instruments and methods, other chemical processes, adsorption water/sewage treatment, etc., can solve problems such as large pore size, inability to effectively adsorb phenol molecules, and inability to effectively match phenol nanoscale small molecules , to achieve high application value and realize the effect of dynamic adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

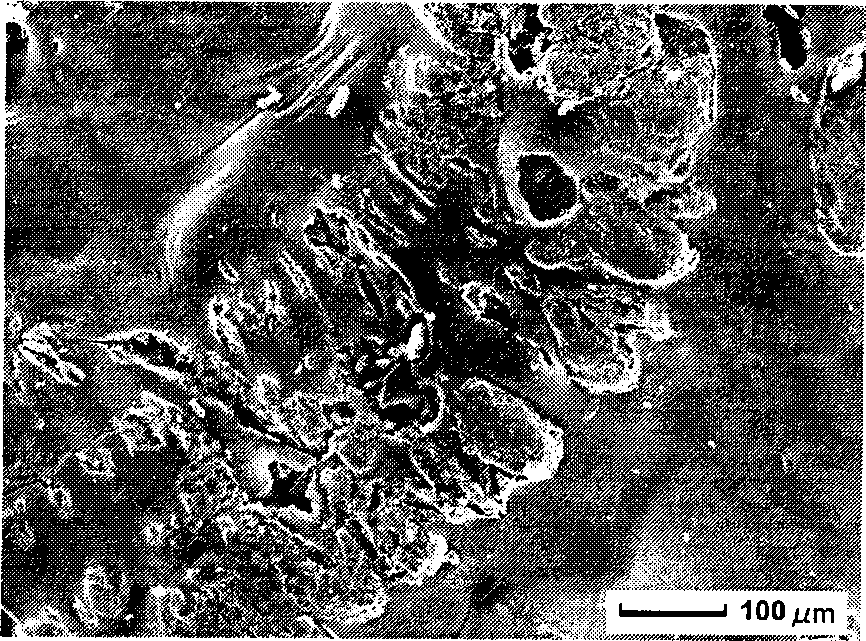

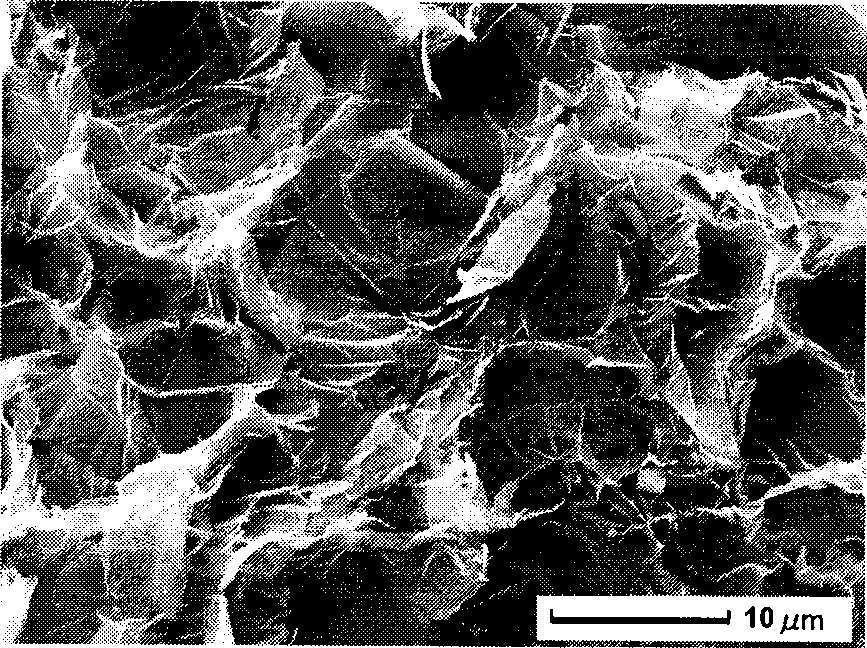

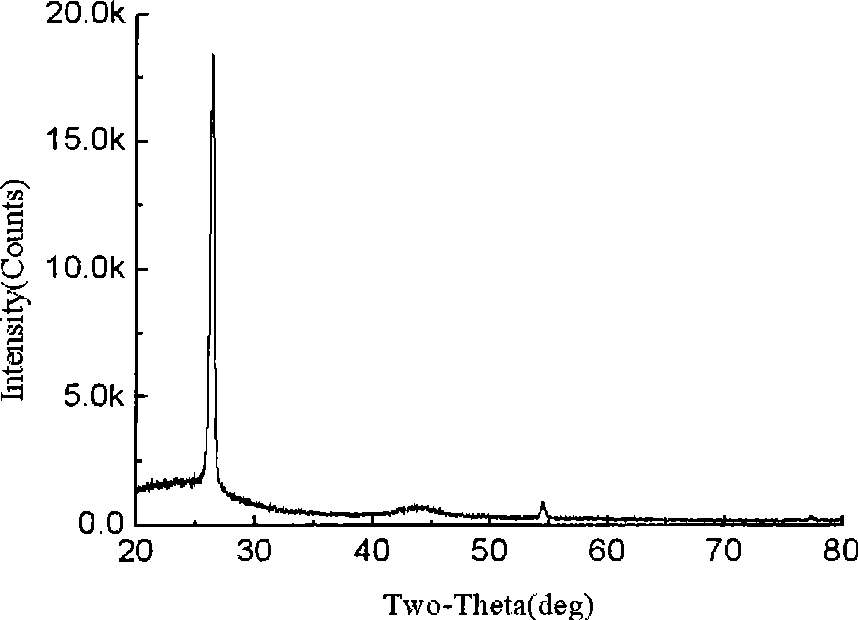

[0015] Example 1: Sucrose is used as carbon source and KOH is used as activator.

[0016] 1. Weigh 0.2g of expanded graphite and place it in a mold for briquetting.

[0017] 2. Immerse the block in a 20% sucrose solution, take it out after 2 hours, and place it in an oven with a temperature of 100° C. for curing for 20 hours.

[0018] 3. The solidified block was placed in a tube furnace for carbonization at 600° C. under a nitrogen atmosphere, and the carbonization time was 6 hours.

[0019] 4. Take out the carbonized material, immerse it in a KOH solution with a mass concentration of 40% for 3 hours, take out the carbonized material and dry it at 80°C, and repeat the dipping for many times.

[0020] 5. The block obtained in 4 was activated in a tube furnace for 1 hour at 600°C under nitrogen atmosphere.

[0021] 6. The obtained composite material was rinsed under running water for 20 hours, and then dried at 80° C. to obtain an expanded graphite-based composite material.

Embodiment 2

[0022] Embodiment 2: take sucrose as carbon source, take K 2 CO 3 for the activator.

[0023] 1. Weigh 0.2g of expanded graphite and place it in a mold for briquetting.

[0024] 2. Immerse the block in a 40% sucrose solution, take it out after 2 hours, and place it in an oven with a temperature of 120° C. for curing for 20 hours.

[0025] 3. The solidified block was placed in a tube furnace for carbonization at 500° C. under a nitrogen atmosphere, and the carbonization time was 5 hours.

[0026] 4. Take out the carbonized material, immerse it in a KOH solution with a mass concentration of 40% for 3 hours, take out the carbonized material and dry it at 80°C, and repeat the dipping for many times.

[0027] 5. The block obtained in 4 was activated in a tube furnace for 2 hours at 500°C under nitrogen atmosphere.

[0028] 6. The obtained composite material was rinsed under running water for 20 hours, and then dried at 80° C. to obtain an expanded graphite-based composite mater...

Embodiment 3

[0029] Example 3: Using sucrose as carbon source, using CO 2 for activation gas.

[0030] 1. Weigh 0.2g of expanded graphite and place it in a mold for briquetting.

[0031] 2. Immerse the block in a 70% sucrose solution, take it out after 1 hour, and place it in an oven with a temperature of 160° C. for curing for 30 hours.

[0032] 3. The solidified block was placed in a tube furnace for carbonization at 300° C. under a nitrogen atmosphere, and the carbonization time was 4 hours.

[0033] 4. Place the block obtained in 4 in a tube furnace and pass CO at 900°C 2 gas, and activated for 6 hours to obtain an expanded graphite-based composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com