Grinding disc type efficient crushing device for plastic syringe type medical waste

A high-efficiency crushing technology for medical waste, applied in the medical field, can solve problems such as incomplete crushing, inability to concentrate discharge, and environmental pollution, and achieve the effects of improving screening efficiency, increasing screening speed, and avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

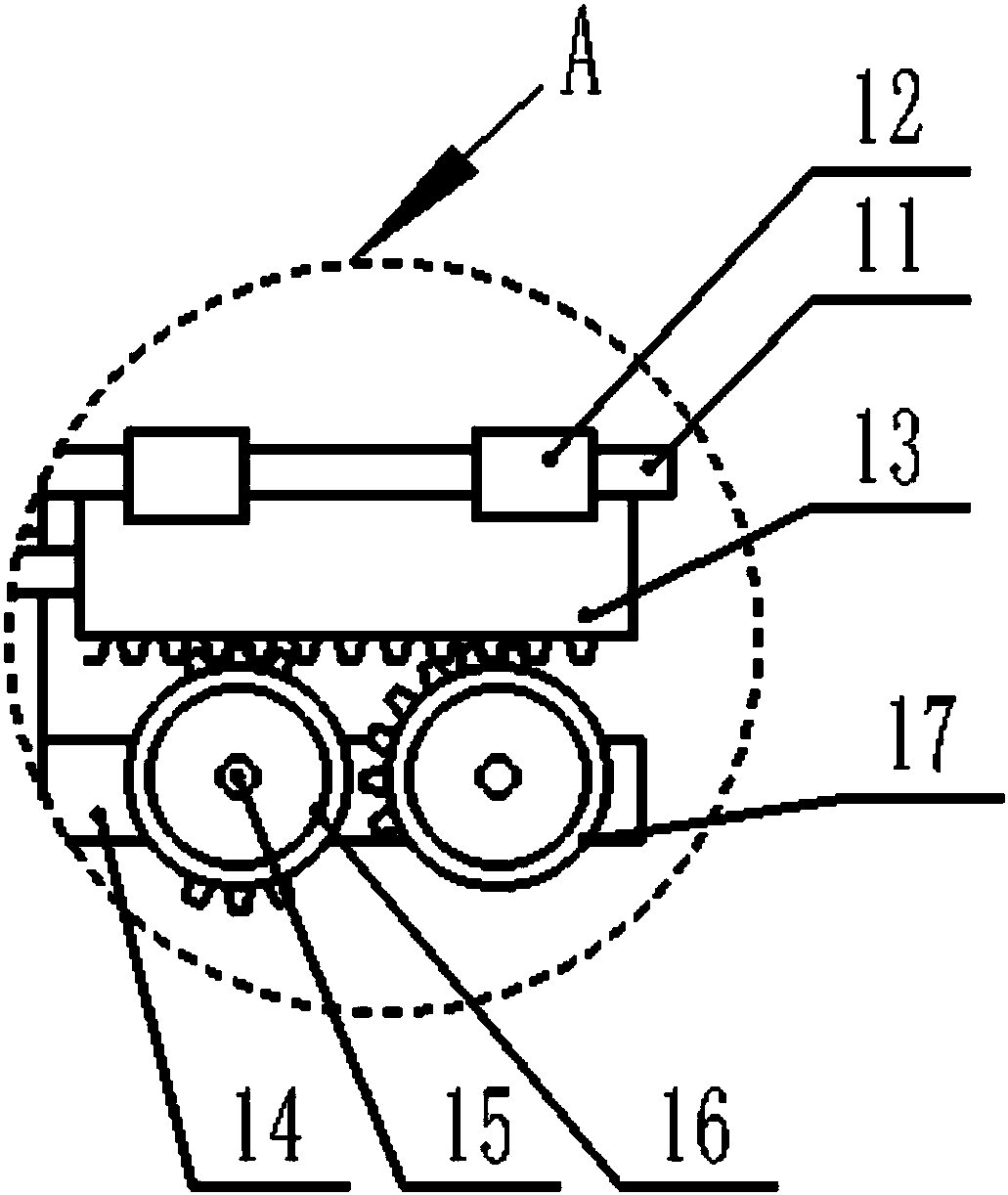

[0023] see Figure 1-3 , a grinding disc-type plastic needle tube type medical waste high-efficiency crushing device, including a base 1, a crushing box 2, a fixed grinding disc 4, a rotating grinding disc 5, a fine grinding roller 8, a driving motor 15 and a collecting tank 24, and the base 1 is provided with There is a crushing box 2, and the crushing box 2 and the base 1 are fixedly connected by bolts. The upper center of the crushing box 2 is fixedly equipped with a crushing motor 3, and the output shaft of the crushing motor 3 extends downward and vertically into the crushing box. 2 inside, the inside of the crushing box 2 is also fixedly installed with a fixed grinding disc 4, the surface of the fixed grinding disc 4 is provided with a material leakage hole, the lower side of the fixed grinding disc 4 is provided with a rotating grinding disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com