Method for producing a flow sensor based on a thin film, and such a flow sensor

A flow sensor and substrate technology, applied in the direction of measuring flow/mass flow, liquid/fluid solid measurement, instruments, etc., to achieve the effect of reduced manufacturing cost and simple integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

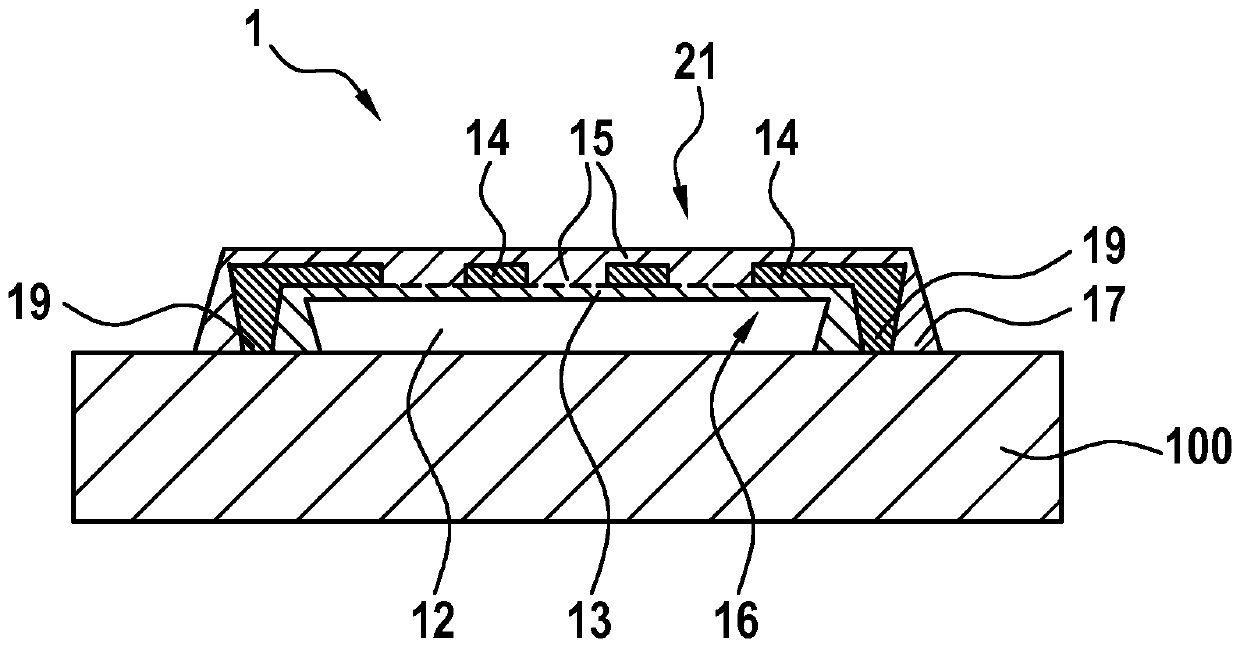

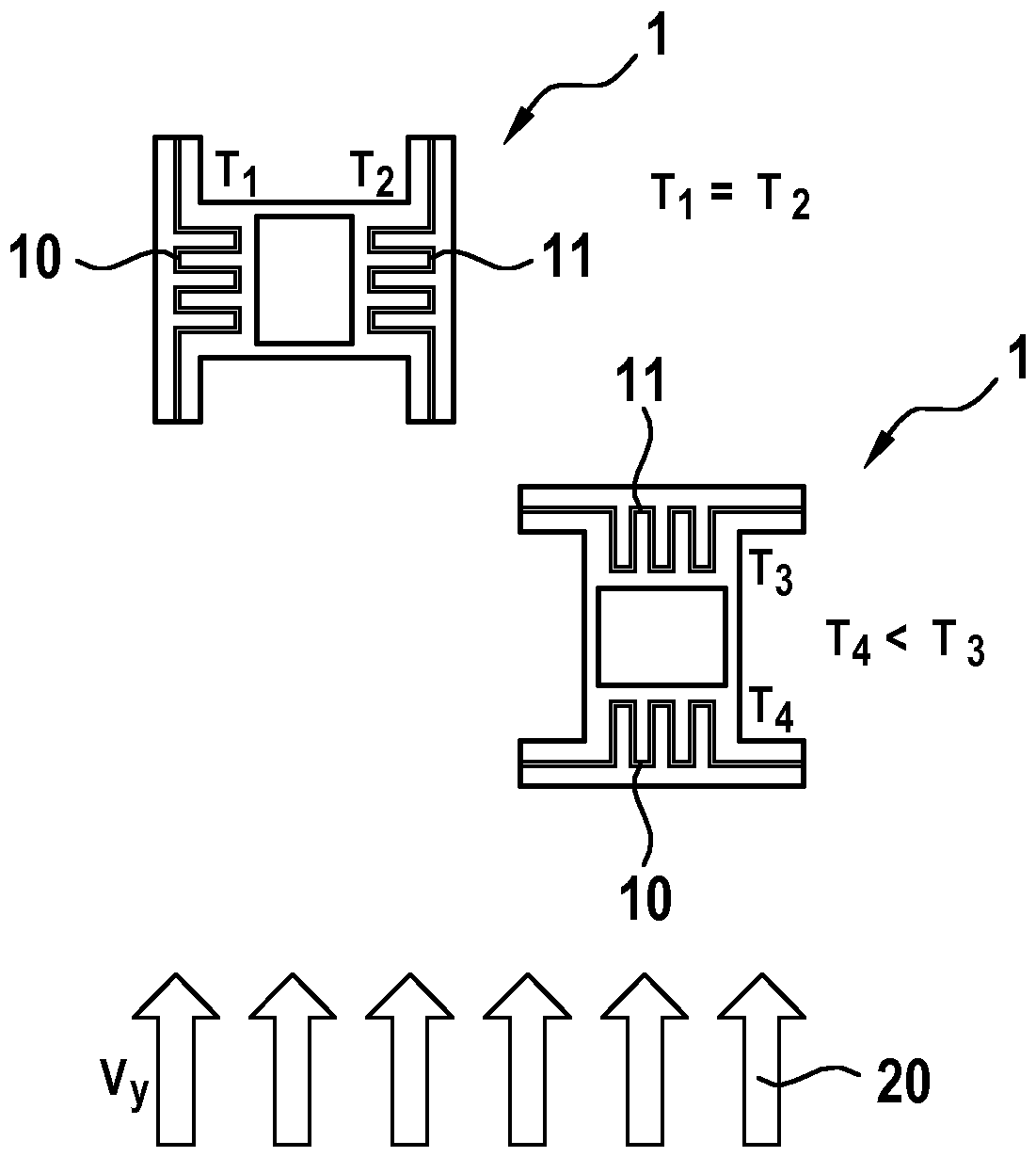

[0023] figure 1 A possible embodiment of a flow sensor 1 , which is formed on a substrate not shown, is shown by way of example. The flow sensor 1 has a carrier structure 21 which consists of multiple layers of photoresist. Two heating and temperature measuring elements 10 and 11 are accommodated in the carrier structure 21 , which are arranged spatially separated from one another and which are connected to the substrate via electrical connections 19 . The protruding electrical connection 19 is accommodated in a connecting arm 17 which is an integral part of the carrier structure 21 and which surrounds the electrical connection 19 . Centrally located between the heating and temperature measuring elements 10 , 11 is a structuring 18 , which is shown simplified as a free space.

[0024] The heating and temperature measuring elements 10 and 11 are built by deposited metal 14 and have a meandering structure in the center.

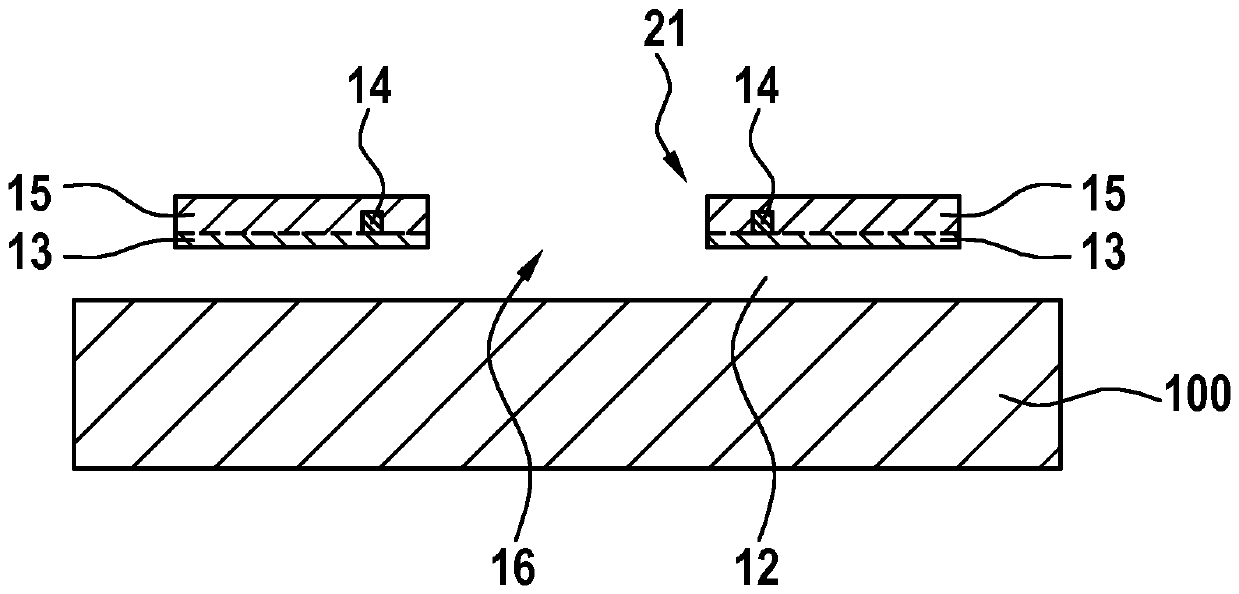

[0025] figure 2 A cross-sectional view of the flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com