Multi-output Scott transformer used for subway

A Scott transformer, multi-output technology, applied in the field of transformers, can solve problems such as difficulty in meeting power supply requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

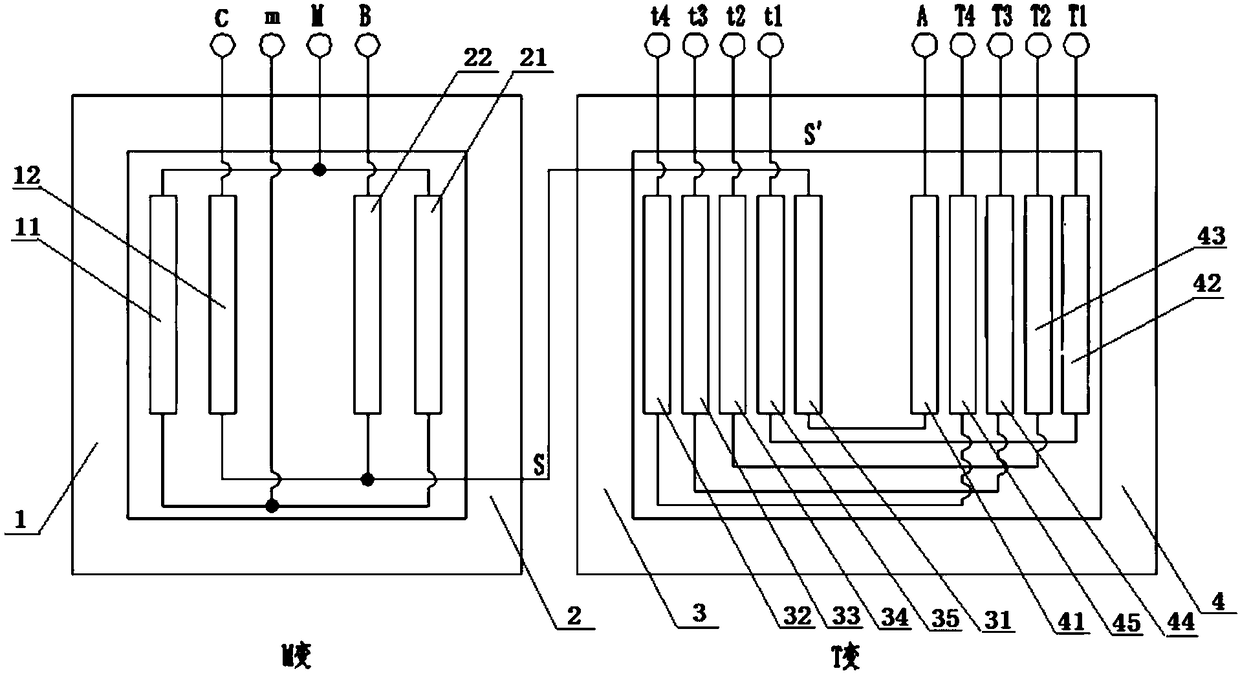

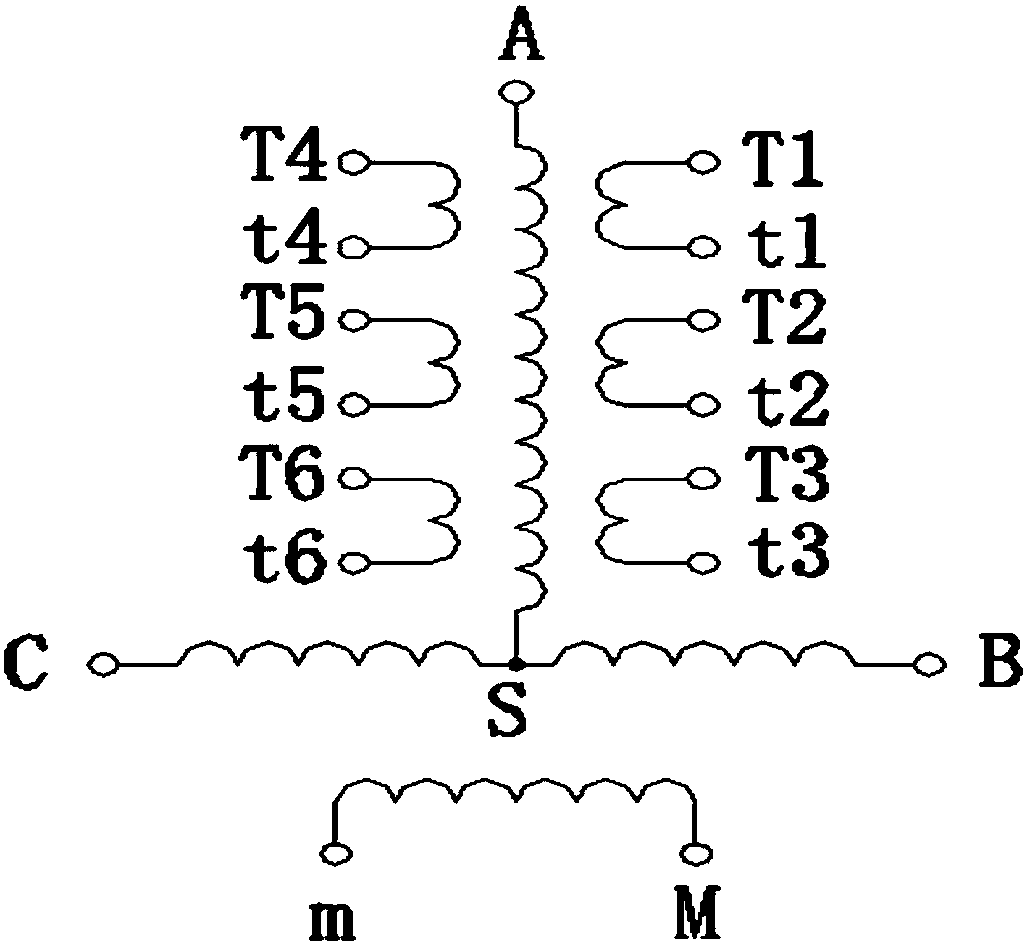

[0031] figure 1 with figure 2 Shows a structure diagram and wiring schematic diagram of a multi-output Scott transformer for subways. This example uses a transformer that transforms T to low voltage for four-winding output. Due to actual needs, the output of the low voltage winding of T can be changed Way of design.

[0032] Such as figure 1 As shown, the multi-output Scott transformer for subway provided by this embodiment includes two single-phase transformers, M-transformer and T-transformer. The M-transformer is provided with a M-transformer first main column 1 and an M-transformer second main column 2. The variant is provided with a T-variable first main column 3 and a T-variable second main column 4;

[0033] The first main column 1 of the M variable is symmetrical to the second main column 2 of the M variable. Specifically, the first main column 1 of the M variable is connected with a layer of low voltage winding (11) and a layer of high voltage winding (12) from the ins...

Embodiment 2

[0044] This embodiment is a preferred embodiment based on the first embodiment. The difference from the first embodiment is that the T-changed first main column 3 and the T-changed second main column 4 are respectively connected with 2-6 layers from the inside to the outer casing. Low-voltage winding and one-layer high-voltage winding, that is, 2≤N≤6.

[0045] In a further preferred solution of this embodiment, the first main column 3 of the T variable is connected with four layers of low voltage windings and one layer of high voltage windings from the inside to the outer casing, that is, N=4. The four-layer low-voltage windings are respectively a first-layer low-voltage winding 32, a second-layer low-voltage winding 33, a third-layer low-voltage winding 34, and a fourth-layer low-voltage winding 35. The outside of the fourth-layer low-voltage winding 35 is a high-voltage winding 31;

[0046] The second main column 4 of the T-substation and the first main column 3 of the T-substati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com