Ferricyanide composite electrode material preparation method and applications of ferricyanide composite electrode material in detection of hydrogen peroxide

A composite electrode, ferricyanide technology, applied in the direction of material analysis, material analysis, material electrochemical variables, etc. by electromagnetic means, to achieve the effects of simple preparation, improved response sensitivity, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

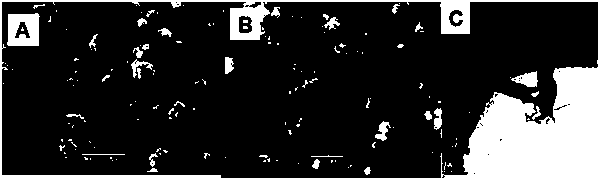

[0031] LiPB-PANI-PUCNTs composite preparation steps are as follows:

[0032] (1) Dissolve 50 mL of 1.0 M K 3 Fe(CN) 6 aqueous solution was added to 50 mL of 0.8 M AgNO 3 solution, stirred vigorously for 2 hours to obtain a bright yellow precipitate, filtered, washed with water, and washed with ethanol, and dispersed the precipitate into 100 mL of water.

[0033](2) Add 100 mL of 0.6 M LiCl solution to the above dispersion, stir vigorously for 2 h to obtain a lime green suspension, filter to obtain about 50 mmol / L LiFe(CN) 6 clear yellow liquid.

[0034] (3) Mix 20 µL aniline+3 mL 1.0 M HCl+27 mL 50 mmol / L Li 3 Fe(CN) 6 Put in the reactor. Then put the installed reactor into an electric heating constant temperature drying oven at 120 °C, and react for 24 h. After the reaction time was over, the reaction kettle was taken out from the electric constant temperature drying oven. After cooling for a period of time, the solution in the reaction kettle was poured into a beaker...

Embodiment 2

[0044] LiPB-PANI-PUCNTs composite preparation steps are as follows:

[0045] (1) Dissolve 50 mL of 1.0 M K 3 Fe(CN) 6 aqueous solution was added to 100 mL of 0.8 M AgNO 3 solution, stirred vigorously for 2 hours to obtain a bright yellow precipitate, filtered, washed with water, and washed with ethanol, and dispersed the precipitate into 100 mL of water.

[0046] (2) Add 100 mL of 1.0 M LiCl solution to the above dispersion, stir vigorously for 2 h to obtain a lime green suspension, filter to obtain about 0.1 mol / L LiFe(CN) 6 clear yellow liquid.

[0047] (3) Mix 40 µL aniline+3 mL 1.0 M HCl+27 mL 50 mmol / L Li 3 Fe(CN) 6 Put in the reactor. Then put the installed reactor into an electric heating constant temperature drying oven at 140 °C, and react for 24 h. After the reaction time was over, the reaction kettle was taken out from the electric constant temperature drying oven. After cooling for a period of time, the solution in the reaction kettle was poured into a beak...

Embodiment 3

[0051] LiPB-PANI-PUCNTs composite preparation steps are as follows:

[0052] (1), (2) are the same as Example 1.

[0053] (3) Mix 100 µL aniline+3 mL 1.0 M HCl+27 mL 50 mmol / L Li 3 Fe(CN) 6 Put in the reactor. Then put the installed reactor into an electric heating constant temperature drying oven at 160 °C, and react for 24 h. After the reaction time was over, the reaction kettle was taken out from the electric constant temperature drying oven. After cooling for a period of time, the solution in the reaction kettle was poured into a beaker, and then centrifuged to obtain a black-blue LiPB-PAn precipitate. The obtained precipitate was washed with ethanol, and finally a dark blue LiPB-PAn precipitate was obtained. The obtained LiPB-PAn precipitate was dried in an electric thermostat oven at 80 °C for 24 h.

[0054] (4) 100 μl aniline and 0.05g PUCNTs and 3 ml 1.0 mol / L HCl and 27 ml Li 3 Fe(CN) 6 The precursors were mixed and placed in a reaction kettle, heated at 160 °C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com