Pressure pipeline crack identification method based on distributed optical fiber sensing technology

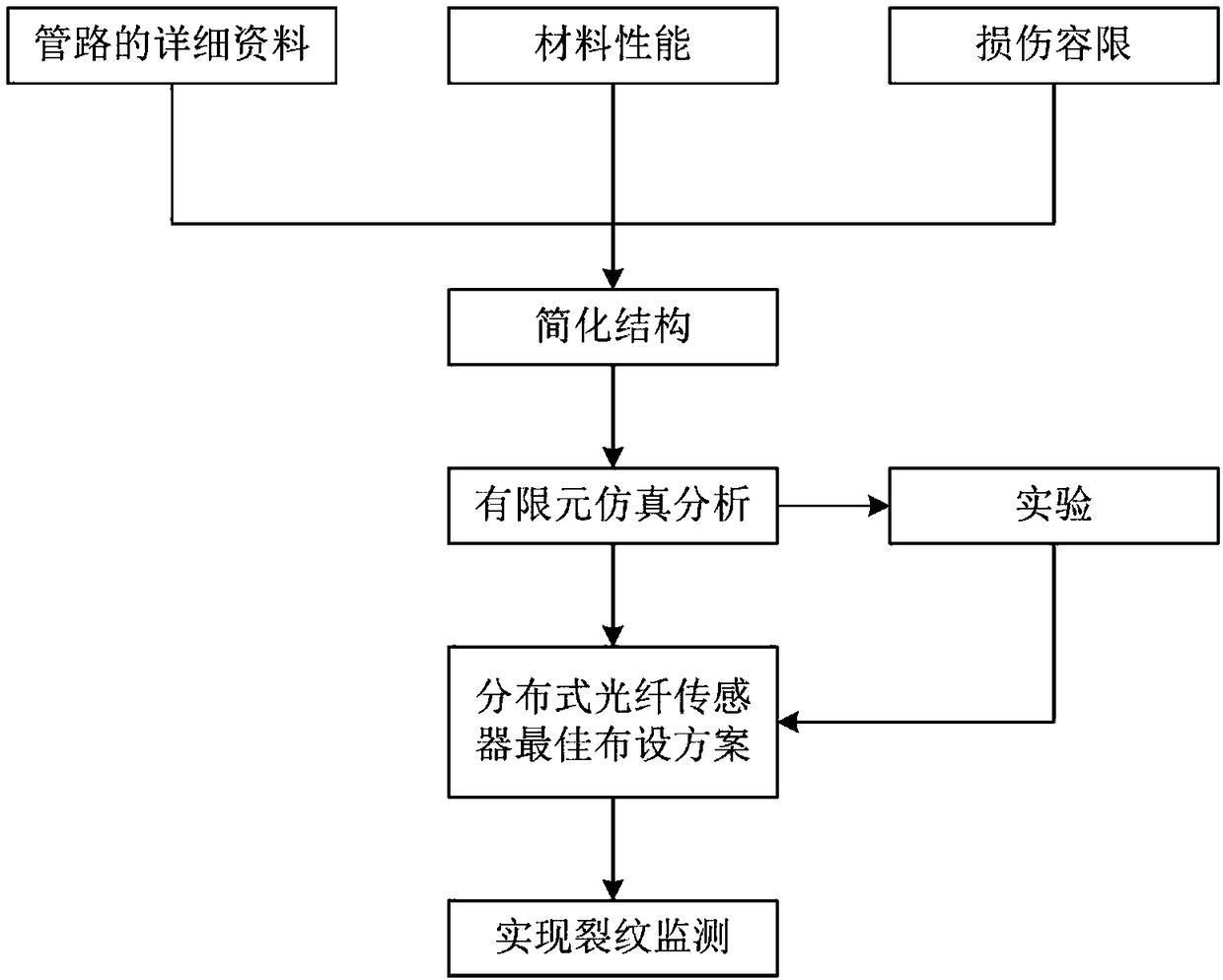

A technology of distributed optical fiber and pressure pipeline, which is applied in the direction of transmitting sensing components by optical devices, testing the strength of materials by applying stable tension/pressure, and analyzing materials. Structural online health monitoring, missed detection and other problems, to achieve the effect of optimal layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] Embodiment: Taking a typical pipeline of an aircraft as an example, according to a pressure pipeline crack identification method based on distributed optical fiber sensing technology provided by the present invention, the identification and location of pipeline cracks are realized. The specific steps are as follows:

[0039] Step 1: Obtain detailed information, material performance data and damage tolerance of the tested pressure pipeline;

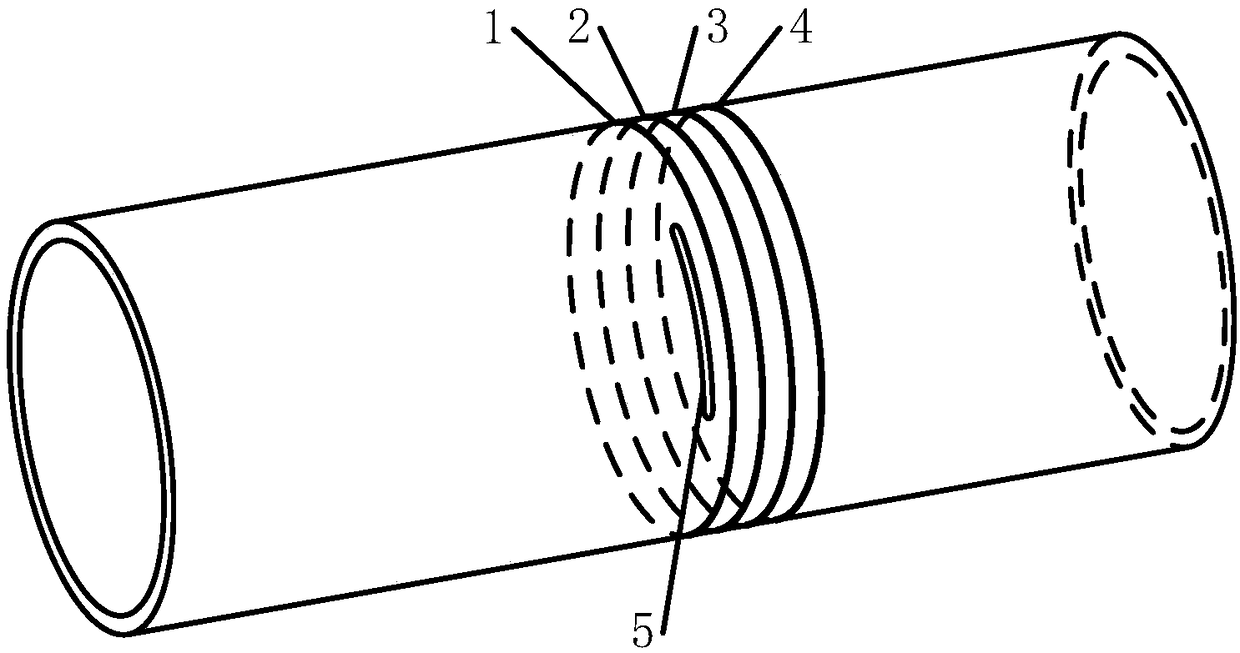

[0040] This embodiment takes a straight pipe section of a typical pipeline of an aircraft, such as figure 1 As shown, the outer diameter of the pipeline is 48mm, the length is 400mm, and the thickness is 2mm. There is a circumferential crack with a depth of 1mm on the outer surface of the pipeline. The maximum internal pressure of the test is 10MPa; the material used for the pipeline is 304 stainless steel, and the elastic modulus of the material It is 193GPa, Poisson's ratio is 0.3, and the yield limit is 207MPa;

[0041] Step 2: Pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| Poisson's ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com