Electromagnetic switching valve and high-pressure fuel pump

An on-off valve, electromagnetic technology, applied in the field of fuel high-pressure pump, can solve problems such as weakening motion, and achieve the effect of reducing switching time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

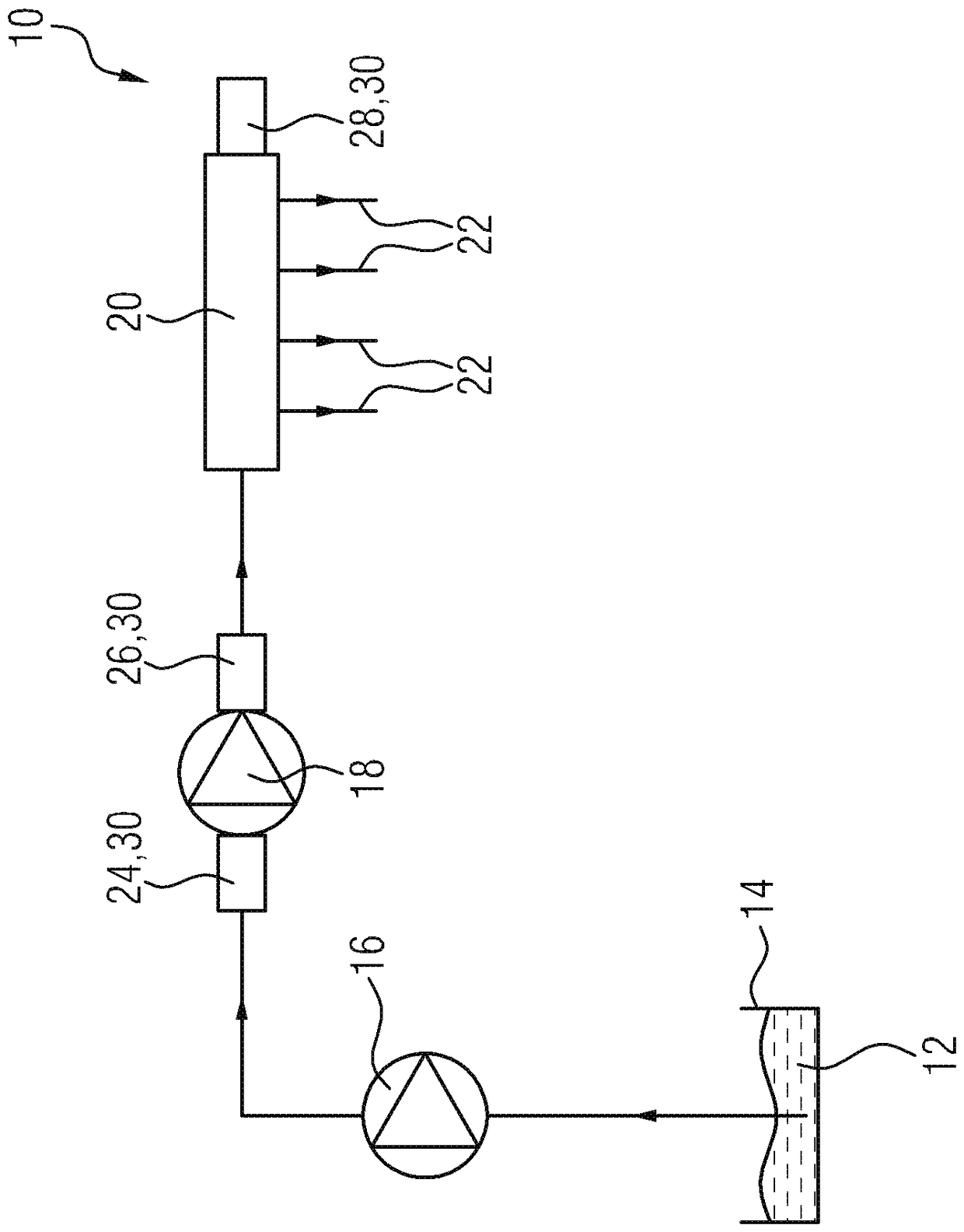

[0041] figure 1A schematic overview of a fuel injection system 10 of an internal combustion engine is shown, which delivers fuel 12 from a tank 14 to injectors 22 via a prefeed pump 16 , a high-pressure fuel pump 18 and a high-pressure fuel accumulator 20 , the injector then injects fuel 12 into the combustion chamber of the internal combustion engine.

[0042] The fuel 12 is introduced into the high-pressure fuel pump 18 via an inlet valve 24 , is discharged from the high-pressure fuel pump 18 via an outlet valve 26 under pressure, and is then conveyed to the fuel high pressure accumulator 20 . A pressure regulating valve 28 is arranged on the high-pressure fuel accumulator 20 in order to be able to regulate the pressure of the fuel 12 in the high-pressure fuel accumulator 20 .

[0043] Both the inlet valve 24 and the outlet valve 26 as well as the pressure regulating valve 28 can be designed as electromagnetic switching valves 30 and can therefore be actively operated.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com