Foundation unit for steel structure houses

A steel structure and housing technology, applied in the direction of infrastructure engineering, construction, etc., can solve the problems of waste of wood, house foundation sinking, structure is not strong, etc., to achieve the effect of avoiding distortion and deformation, stable connection relationship, and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

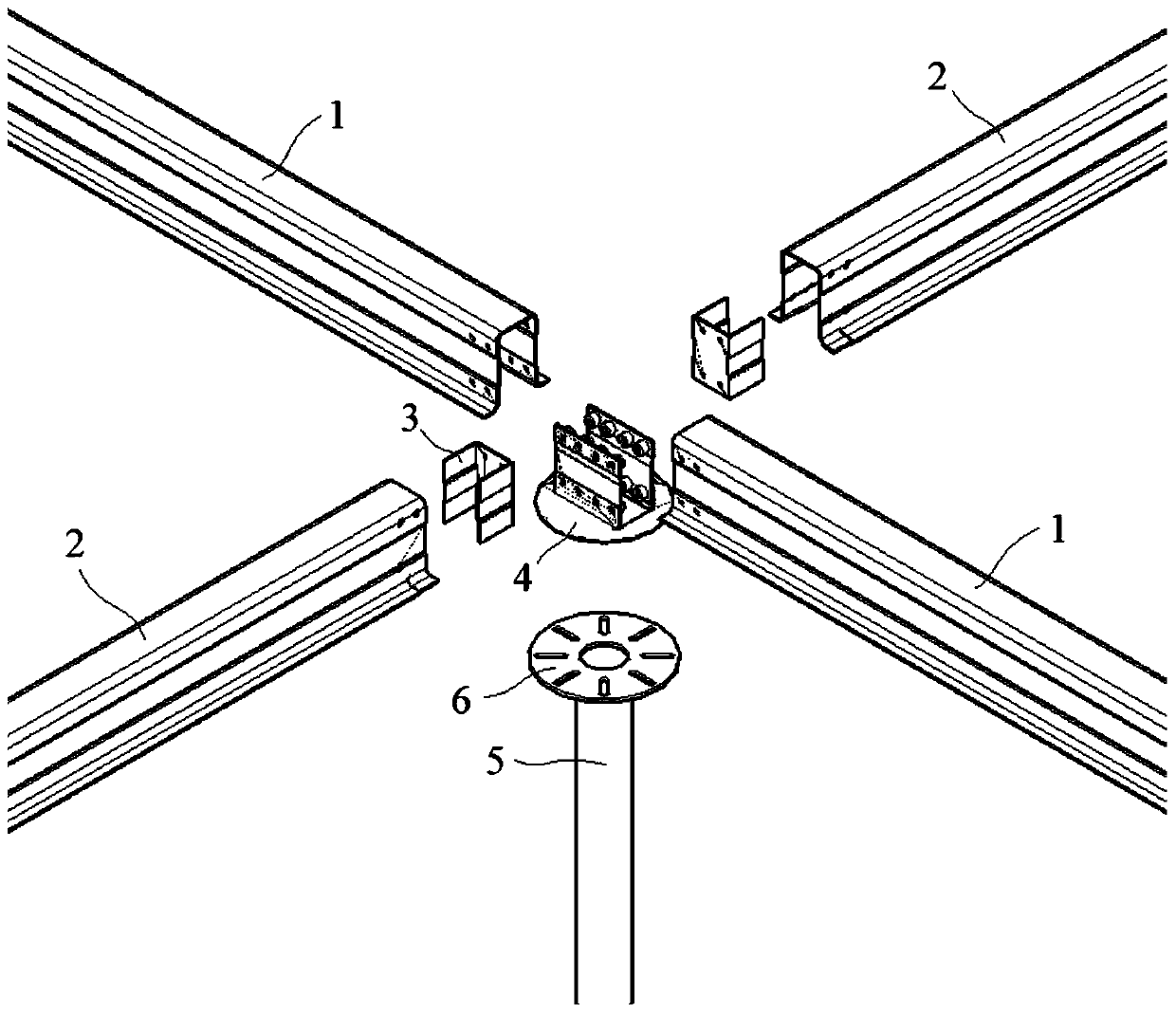

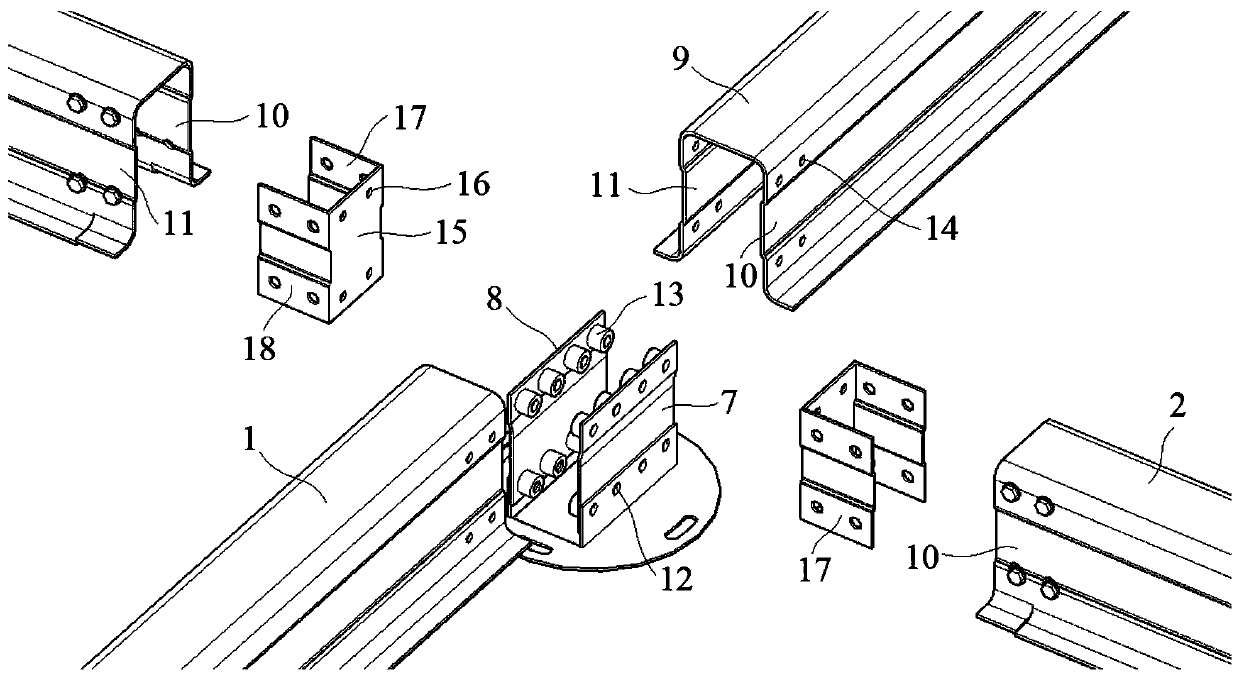

[0029] Example 1: A foundation unit for a steel structure house, comprising two X beams 1, two Y beams 2, two connecting pieces 3, a connecting plate 4, and a ground pile 5, and the two X beams 1 are respectively connected to The plate 4 is installed and connected, the two Y beams 2 are installed and connected to the connecting plate 4 and the X beam 1 through two connectors 3, and the ground pile 5 is installed on the lower surface of the connecting plate 4 through a mounting plate 6. The upper surface of the connecting plate 4 is symmetrically provided with a first vertical plate 7 and a second vertical plate 8. The two ends of the first vertical plate 7 are installed and connected to the two X beams 1 respectively, and the two ends of the second vertical plate 8 are respectively connected with 2 X beams 1 installation connection;

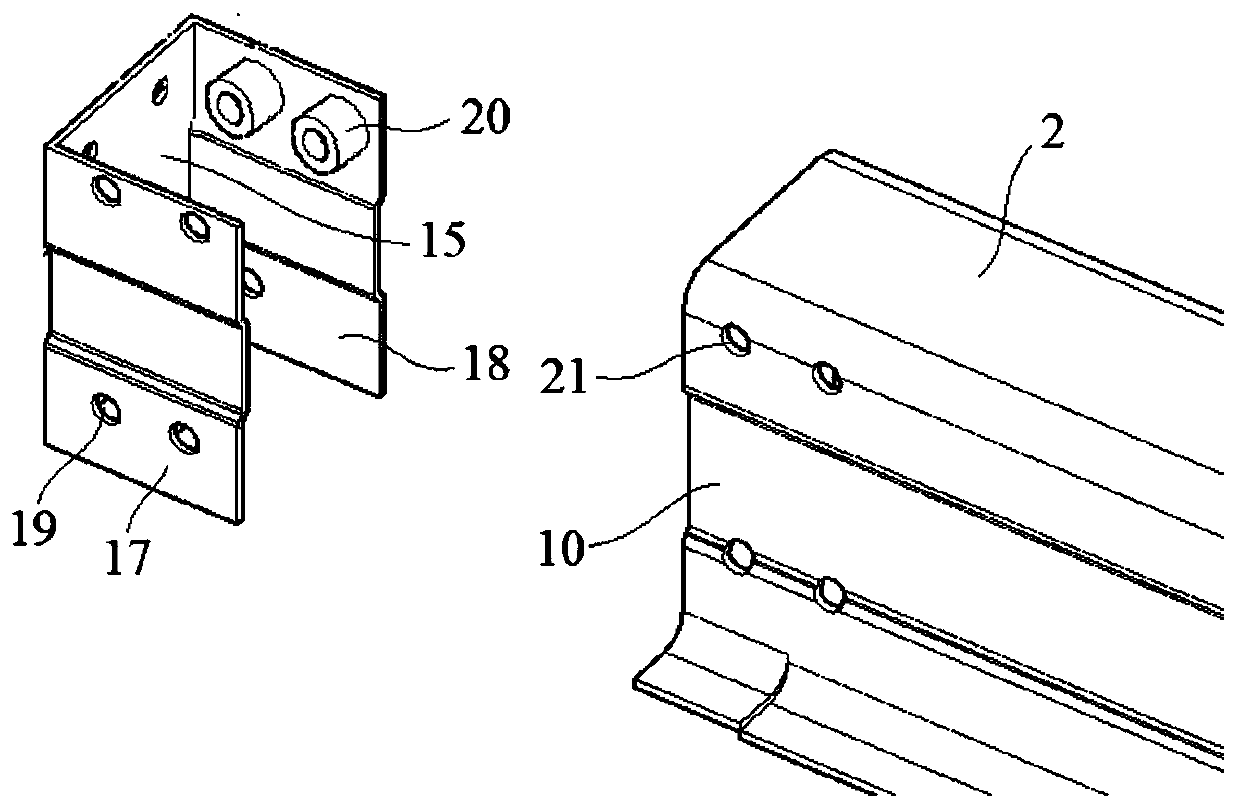

[0030] Each of the X beams 1 and Y beams 2 further includes a top plate 9 and a first side plate 10 and a second side plate 11 located on both side...

Embodiment 2

[0037] Embodiment 2: A foundation unit for a steel structure house, including two X beams 1, two Y beams 2, two connecting pieces 3, a connecting plate 4, and a ground pile 5, and the two X beams 1 are respectively connected to The plate 4 is installed and connected, the two Y beams 2 are installed and connected to the connecting plate 4 and the X beam 1 through two connectors 3, and the ground pile 5 is installed on the lower surface of the connecting plate 4 through a mounting plate 6. The upper surface of the connecting plate 4 is symmetrically provided with a first vertical plate 7 and a second vertical plate 8. The two ends of the first vertical plate 7 are installed and connected to the two X beams 1 respectively, and the two ends of the second vertical plate 8 are respectively connected with 2 X beams 1 installation connection;

[0038] Each of the X beams 1 and Y beams 2 further includes a top plate 9 and a first side plate 10 and a second side plate 11 located on both si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com