Surface treatment method for ABS plastic electroplating

A ABS plastic and surface treatment technology, which is applied in the surface treatment field of ABS plastic electroplating, can solve the problems of non-wear resistance, high price, non-pollution resistance, etc., achieve excellent conductivity and gloss, shorten the process flow and cost, and facilitate The effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

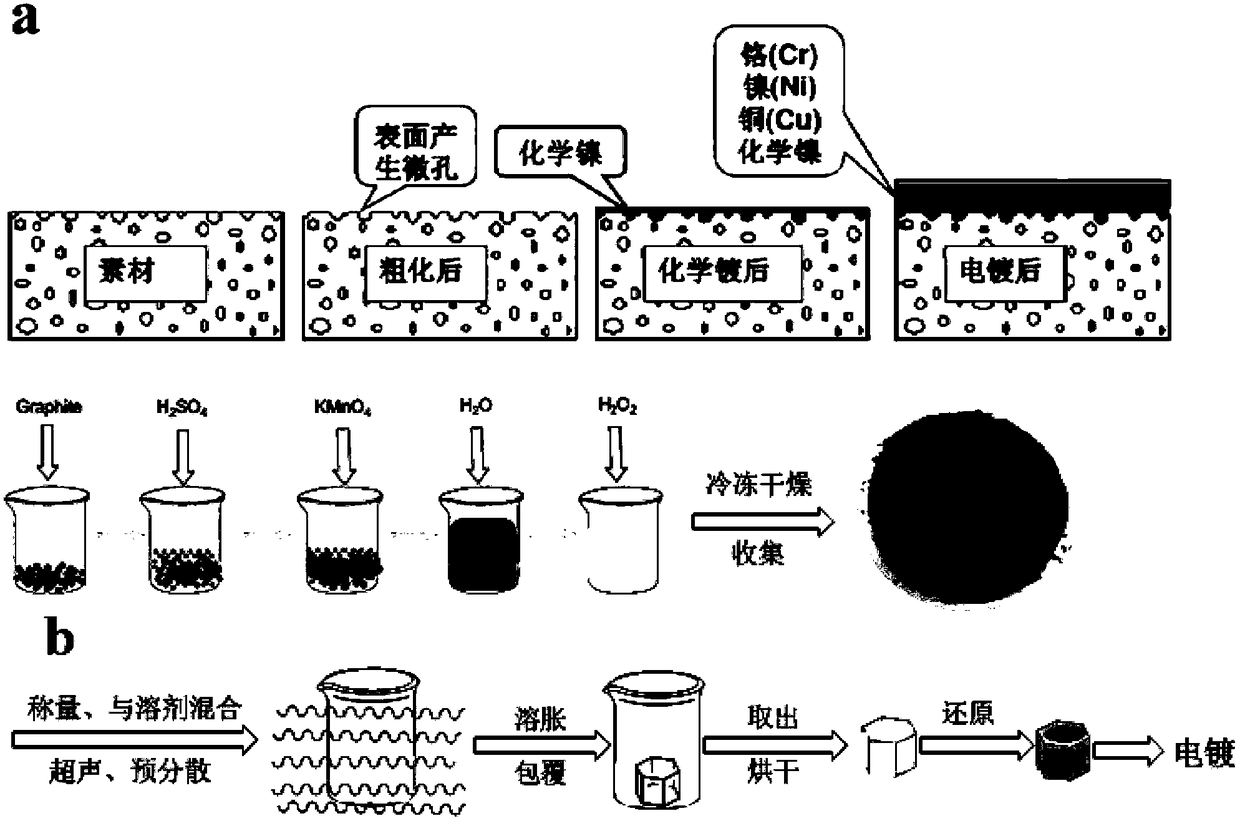

[0042] like figure 1 Shown in b, the surface treatment method for ABS plastic electroplating of the present invention comprises the steps:

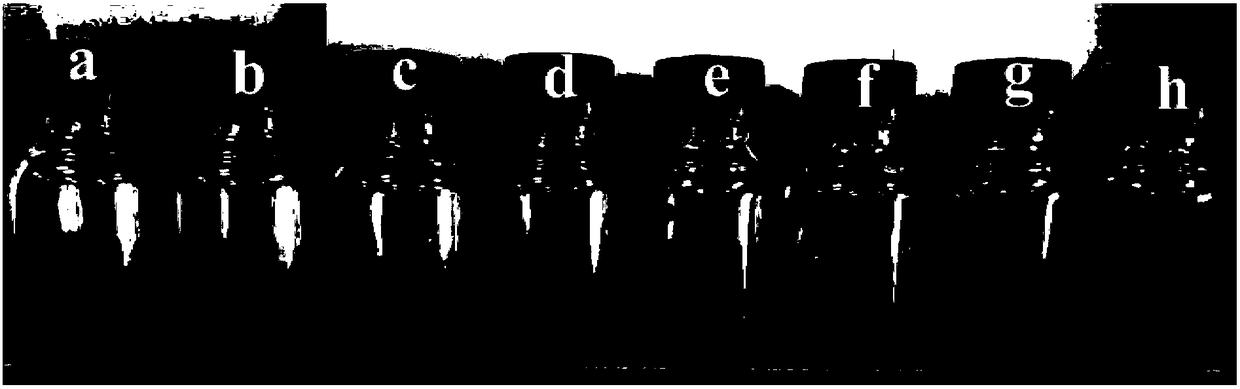

[0043] (1) Prepare degreasing lye, the original such as figure 2 The ABS product shown in a is soaked in the degreasing lye for constant temperature water bath treatment. The constant temperature is 70°C, and the degreasing treatment time is 30 minutes. After that, the lye on the surface of the ABS product is cleaned with distilled water and dried to obtain degreasing ABS. Product spare;

[0044] (2) Measure 200mL THF and 100mL H 2 O, weigh 1.5g GO (graphene oxide, prepared by the Hummers method, the sheet diameter is 1.3~150um, such as figure 2 As shown in b), the three are mixed and ultrasonically dissolved, and the solvent is THF:H 2 O=2:1, GO concentration is the graphene oxide preplating solution of 5mg / mL, such as image 3 as shown in a;

[0045] (3) Soak the above-mentioned degreasing ABS product in the above-mentioned grap...

Embodiment 2

[0048] like figure 1 Shown in b, the surface treatment method for ABS plastic electroplating of the present invention comprises the steps:

[0049] (1) Prepare degreasing lye, the original such as figure 2 The ABS product shown in a is soaked in the degreasing lye for constant temperature water bath treatment. The constant temperature is 70°C, and the degreasing treatment time is 30 minutes. After that, the lye on the surface of the ABS product is cleaned with distilled water and dried to obtain degreasing ABS. Product spare;

[0050] (2) Measure 400mL THF and 100mL H 2 O, weigh 2.5g GO (graphene oxide, prepared by the Hummers method, sheet diameter is 1.3 ~ 150um), mix the three and carry out ultrasonication and dissolution, and prepare the solvent as THF:H 2 O=4:1, GO concentration is the graphene oxide preplating solution of 5mg / mL, such as image 3 as shown in b;

[0051] (3) Soak the above-mentioned degreasing ABS product in the above-mentioned graphene oxide pre-pl...

Embodiment 3

[0054] like figure 1 Shown in b, the surface treatment method for ABS plastic electroplating of the present invention comprises the steps:

[0055] (1) Prepare degreasing lye, the original such as figure 2 The ABS product shown in a is soaked in the degreasing lye for constant temperature water bath treatment. The constant temperature is 70°C, and the degreasing treatment time is 30 minutes. After that, the lye on the surface of the ABS product is cleaned with distilled water and dried to obtain degreasing ABS. Product spare;

[0056] (2) Measure 200mL THF, 50mL cyclohexanone and 50mL H 2 O, weigh 1.5g GO (graphene oxide, prepared by the Hummers method, sheet diameter is 1.3 ~ 150um), mix the four and carry out ultrasonication and dissolution, and prepare the solvent as THF: cyclohexanone: H 2 O=4:1:1, GO concentration is the graphene oxide preplating solution of 5mg / mL, as image 3 as shown in c;

[0057](3) Soak the above-mentioned degreasing ABS product in the above-m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com