Modified asphalt as well as continuous production method and system thereof

A technology of modified asphalt and production system, applied in the processing of tar asphalt/petroleum asphalt/natural asphalt, processing tar asphalt/petroleum asphalt/natural asphalt by heating, processing tar asphalt/petroleum asphalt/natural asphalt by chemical methods, etc. , can solve the problems of narrow molecular weight distribution, high content of modified asphalt, and high automation level, and achieve the effect of narrow distribution range, high first-class product rate, and improved automation level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

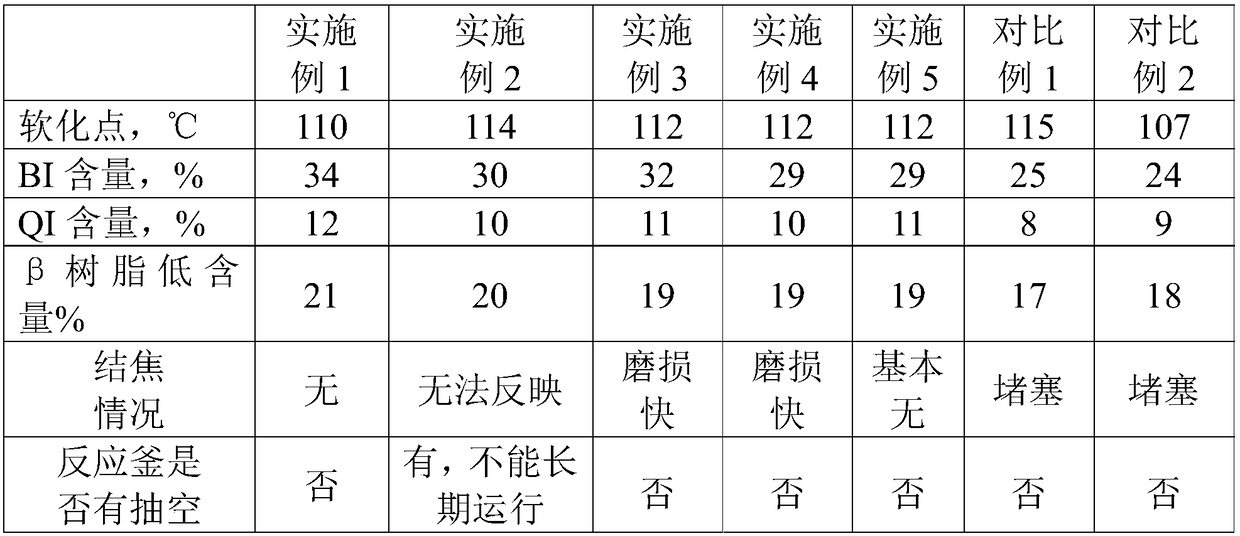

[0044] In the prior art, the asphalt is usually transported to the reaction kettle through a high standard difference for reaction, but the inventors of the present invention have found that the method of high standard difference can easily cause the pressure imbalance of the reactor parts at all levels, and the asphalt The degree of evaporation in the reactors at all levels is different. When the evaporation amount is small, the gas phase pressure is small, and vice versa, and it changes continuously with the production process. Therefore, it will lead to the evacuation of some reactors and the occurrence of asphalt blockage. Phenomenon. The inventors of the present invention have found through research that by setting the power supply unit 10 between the discharge port of the asphalt liquid heating unit 12 and the feed port of the asphalt polymerization reaction system 2, the asphalt that reaches the predetermined reaction temperature Transporting to the feed port of the asp...

Embodiment 1

[0075] This example is used to illustrate the continuous production system and process of modified asphalt provided by the present invention.

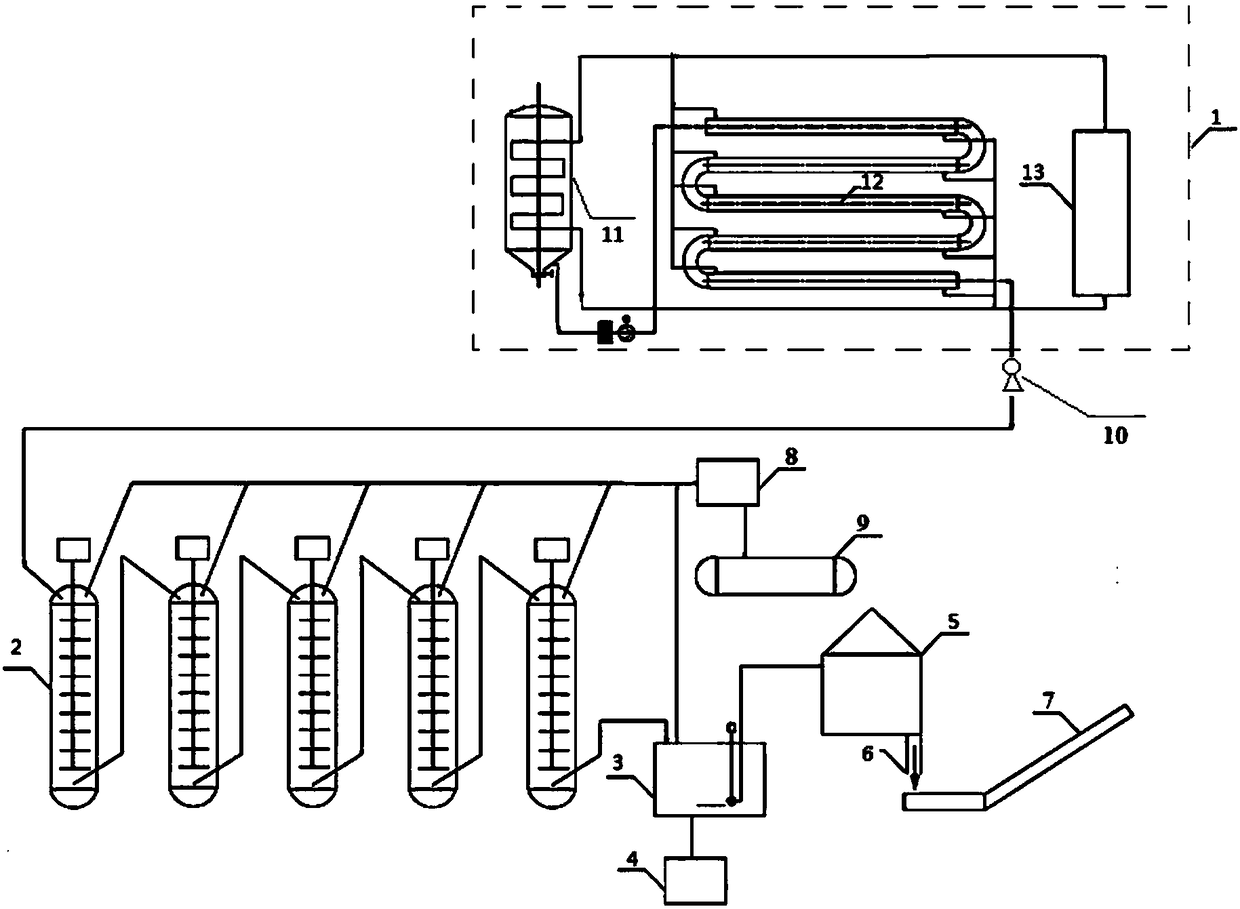

[0076] Modified asphalt continuous production system: such as figure 1 As shown, the asphalt polymerization reaction system includes four-stage reactors set in series (the height of the reactor is 3m, the diameter of ф1m, and a built-in blade stirrer) and the first-stage spare reactor.

[0077] Continuous production method of modified asphalt: introduce the aforementioned asphalt liquid into the asphalt liquid storage unit 11 (with a molten salt insulation layer outside to maintain the temperature of the asphalt liquid), and pump it into the asphalt heating pipe sleeve through the asphalt feed pump In the inner pipe, the flow rate of asphalt in the inner pipe is 2-2.5m / s, the outer pipe of the asphalt heating sleeve is filled with molten salt, and the mixed material is heated to 380-420°C at a speed of 240°C / h , to obtain the asphalt ...

Embodiment 2

[0081] This example is used to illustrate the continuous production system and process of modified asphalt provided by the present invention.

[0082] Use the modified asphalt continuous production system of Example 1 and carry out the production of modified asphalt according to the modified asphalt continuous production method, the difference is that the asphalt melt is not used as above by adding the asphalt melt to the four-stage reaction including series settings In the bitumen polymerization reaction system 2 of the tank, the bitumen melt is added to the bitumen polymerization reaction system 2 including four-stage reactors arranged in series through a high standard difference, and the high standard difference is 5m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com