Pumpkin enzyme fertilizer and preparation method thereof

An enzyme bacteria and pumpkin technology, applied in the field of enzymes, can solve problems such as insufficient utilization rate, and achieve the effects of bright color, increased yield and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

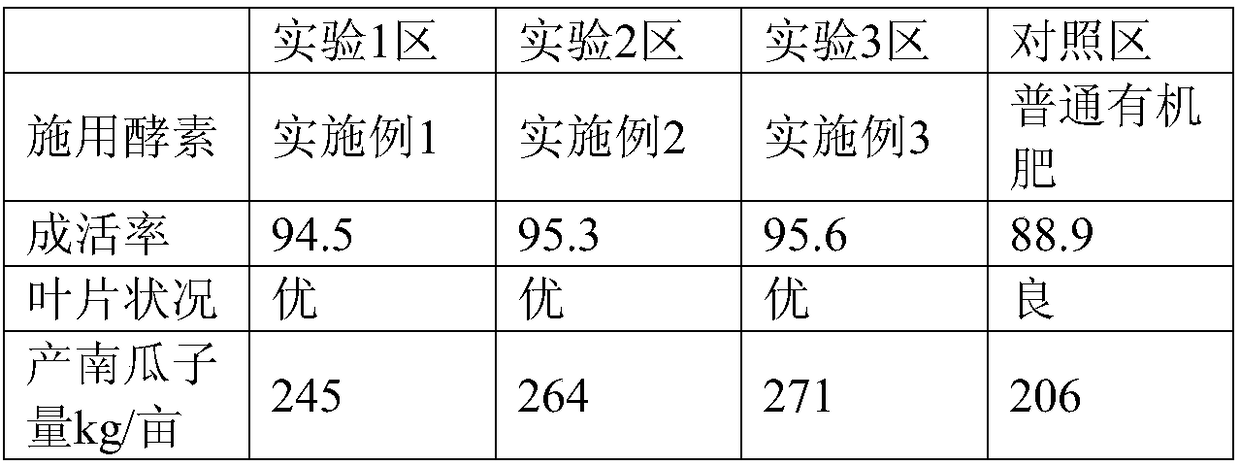

Examples

preparation example Construction

[0034] The present invention also provides a kind of preparation method of pumpkin enzyme bacterial fertilizer, comprising:

[0035] Step 1: Grinding watermelon, pumpkin, tomato and fresh plants through a grinder into puree or chopping into pieces with a length less than 3cm, and then adding them to the fermentation tank;

[0036] Step 2: put yeast, urea, potassium sulfate, superphosphate, zinc sulfate, borax, sugar and water into the fermentation tank, and mix well to obtain a mixed slurry;

[0037] Step 3: after the fermentation tank is covered with a tank cover, and then covered with a layer of plastic film to seal, the mixed slurry obtained in step 2 is fermented in the fermentation tank; the fermentation temperature is preferably normal temperature, and the time is preferably 6 -10 days; for more uniform fermentation, it is preferable to uncover the tank cover and stir 2-3 times during fermentation to stir the raw material components floating on the surface into the botto...

Embodiment 1

[0042] Prepare pumpkin enzyme fertilizer according to the following formula:

[0043] Watermelon 15Kg, pumpkin 40Kg, tomato 10Kg, cabbage leaves 25Kg, yeast 0.5Kg, urea 1Kg, potassium sulfate 1Kg, superphosphate 5Kg, zinc sulfate 0.2Kg, borax 0.5Kg, sugar 0.5Kg, water 200Kg.

[0044] Put non-commercial watermelon, pumpkin, tomato and cabbage leaves into the fermentation tank after being crushed into puree or shredded into pieces less than 3cm in length;

[0045]Put yeast, urea, potassium sulfate, superphosphate, zinc sulfate, borax, brown sugar and water into the fermentation tank and mix well;

[0046] After the fermentation tank is covered with a tank cover, and then covered with a layer of plastic film to seal, carry out natural fermentation for 6 days, during which the tank cover is uncovered and stirred 2-3 times to stir the raw material components floating on the surface into the bottom of the tank , to carry out uniform fermentation;

[0047] After raising the ferment...

Embodiment 2

[0050] Watermelon 20Kg, pumpkin 50Kg, tomato 15Kg, cabbage leaves 35Kg, yeast 1Kg, urea 3Kg, potassium sulfate 2Kg, superphosphate 8Kg, zinc sulfate 0.5Kg, borax 1.5Kg, sugar 1Kg, water 350Kg.

[0051] Put non-commercial watermelon, pumpkin, tomato and cabbage leaves into the fermentation tank after being crushed into puree or shredded into pieces less than 3cm in length;

[0052] Put yeast, urea, potassium sulfate, superphosphate, zinc sulfate, borax, brown sugar and water into the fermentation tank and mix well;

[0053] After the fermentation tank is covered with a tank cover, and then covered with a layer of plastic film to seal, carry out natural fermentation for 10 days, during which the tank cover is uncovered and stirred 2-3 times to stir the raw material components floating on the surface into the bottom of the tank , to carry out uniform fermentation;

[0054] After raising the fermentation temperature of the fermentation tank to 55°C, and continuing to ferment for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com