Fly ash based geopolymer high-strength grouting material and preparation method thereof

A fly ash and polymer technology, applied in cement production, etc., can solve problems such as the inability to meet the strength requirements of grouting materials, poor volume stability of finished products, etc., and achieve the effects of easy implementation, high fluidity and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

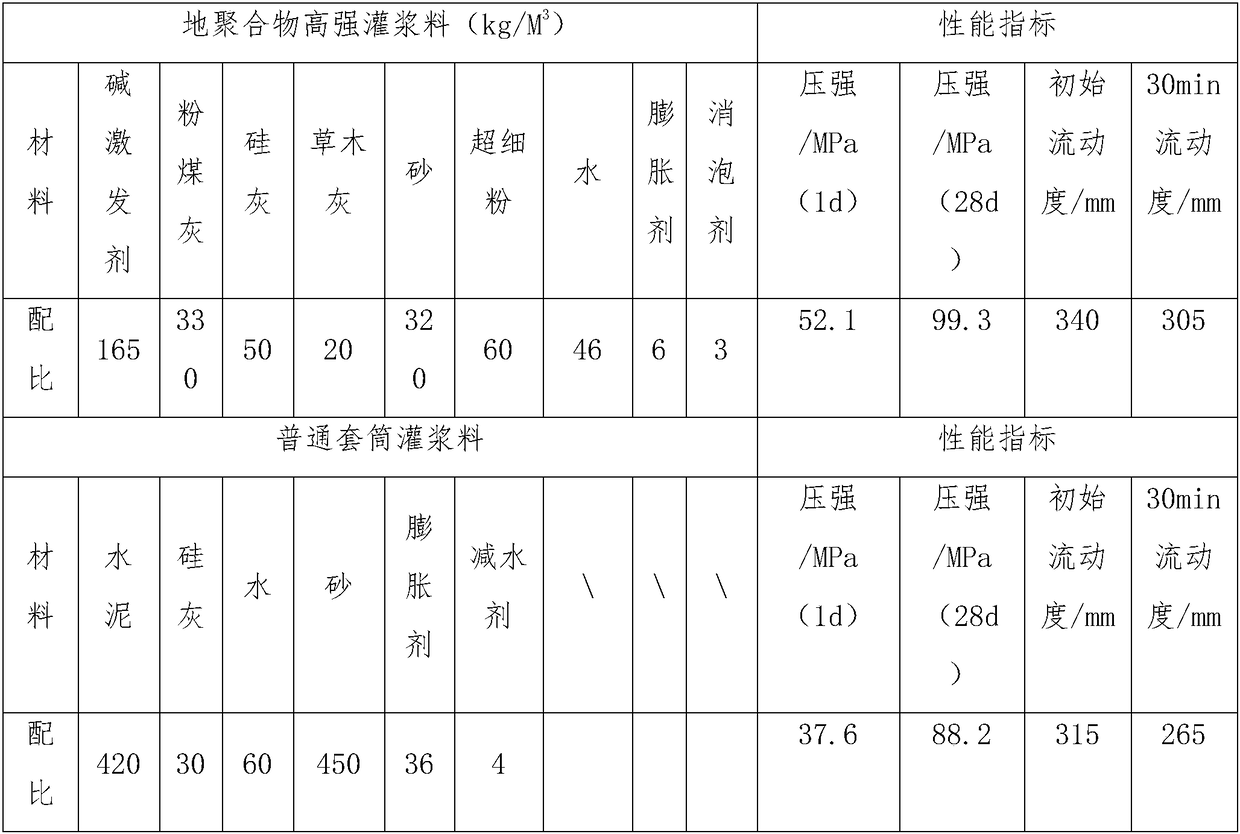

[0031] A fly ash-based polymer high-strength grouting material, comprising the following components and their parts by weight: 10-20 parts of alkali activator, 30-45 parts of fly ash, 2-10 parts of silica fume, 1-5 parts of plant ash, Sand: 30-45 parts, superfine powder: 1-5 parts, expansion agent: 0.1-5 parts, defoamer: 0.1-0.5 parts, water 3-8 parts; Coal ash, silica fume, plant ash and other active materials are used as cementing materials. After being activated by alkali activators, they are mixed with graded sand and then used together with a small amount of expansion agent and defoamer to prepare early strength, rapid hardening, high fluidity, and micro-expansion. high-strength grouting material.

[0032] As a specific scheme, the alkali activator adopts water glass and caustic soda powder with a modulus of 2.0 to 2.5, and is prepared at a mass ratio of 2: 1. The excitation effect of this composite activator is the best. Increasing the caustic soda content will speed up...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| activation index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com